Novel electroweldable high-chromium white wear-resistant cast iron and preparation method thereof

A wear-resistant cast iron and high-chromium technology, which is applied in the field of new electric-weldable high-chromium white anti-wear cast iron, to achieve the effect of clean grain boundaries, weakened splitting, and strong bonding force between grains

Active Publication Date: 2022-06-21

CHANGSHA VIBO WEARABLE MATERIAL CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The present invention aims to provide a new electric-weldable high-chromium white wear-resistant cast iron material, which not only has traditional wear-resistant properties, but more importantly, the material can be directly used for electric welding operations due to the solution of its thermal stress problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0020]The new type of electric-weldable high-chromium white wear-resistant cast iron prepared by the above method has been tested, and the mass percentages of chemical elements are: C: 7%, Cr: 28~30%, Mo: ≤2.5%, Ni: ≤2%, Mn: ≤1%, Si: 0.5%, 57%≤Fe≤59%, and the balance includes impurity elements. The Rockwell hardness of the material is HRC68, and the impact value is 8J.

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Login to View More

Abstract

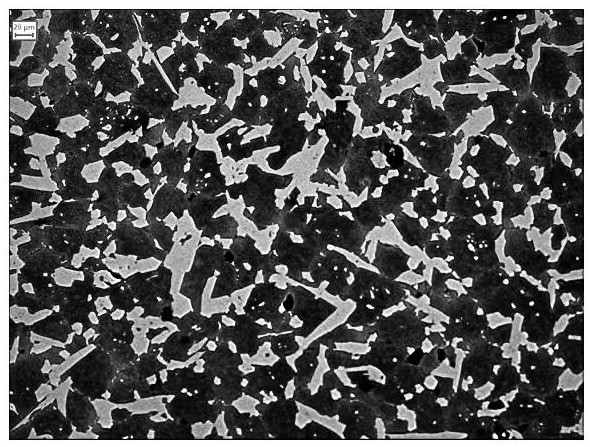

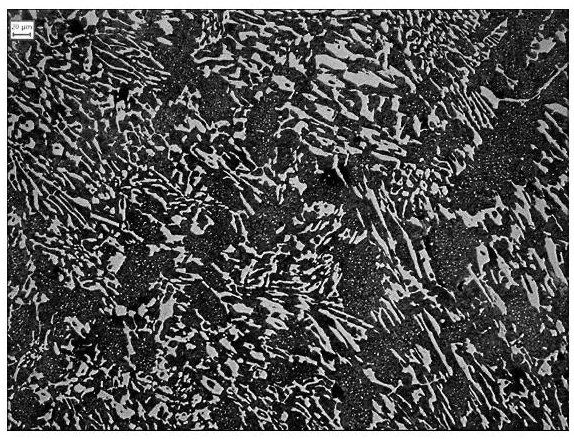

The invention provides novel electroweldable high-chromium white wear-resistant cast iron and a preparation method thereof. The novel electroweldable high-chromium white wear-resistant cast iron comprises the following main chemical elements in percentage by mass: 6-10% of C, 10-40% of Cr and 42.5-82% of Fe, and carbides formed by carbon and chromium in the material are dispersed and distributed in a matrix in a granular form. According to the invention, unique powder is mixed and processed into a porous green body, and then the porous green body is prepared by liquid forging and infiltration processes. The carbon content in the material disclosed by the invention achieves a limit breakthrough and can reach 6% or above, the thermal conductivity coefficient of the material is sharply reduced, and the crack propagation capacity is sharply reduced, so that the problem that the material is extremely easy to crack during heat accumulation is effectively solved; the toughness value of the material can be improved to 5-8 J from 1-2 J of an existing process method while the wear resistance is guaranteed, and the performance of direct electric welding is obtained.

Description

technical field [0001] The invention relates to a cast iron material and a preparation method thereof, in particular to a novel weldable high-chromium white wear-resistant cast iron. Background technique [0002] High chromium white wear-resistant cast iron material has been widely used as the third generation of wear-resistant material. Since there are about 30% carbides in the material and the matrix is mainly martensite, the structure distortion is large and the crack propagation is limited. There are many favorable factors. Once thermal stress exists, the probability of cracking is very high. Therefore, on the one hand, in the actual use or manufacturing process, the high chromium white wear-resistant cast iron material fails or the product scrap rate is high due to uneven heating; on the other hand On the one hand, the long-term understanding of high-chromium white wear-resistant cast iron materials in the industry generally believes that due to the heat concentrated ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C37/10C22C37/08C22C33/08B22F3/03B22D18/02

CPCC22C37/10C22C37/08C22C33/08B22D18/02B22F3/03

Inventor 胡许先许元根刘守礼

Owner CHANGSHA VIBO WEARABLE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com