Construction-used art curtain wall insulation board made of thermoset nonmetallic composite and construction-used art curtain wall insulation board preparation method

A composite material and non-metallic technology, applied in thermal insulation, building components, chemical instruments and methods, etc., can solve problems such as single waterproof performance and thermal insulation performance, difficult to balance waterproof and thermal insulation, and unfavorable building energy saving, etc., to achieve The overall effect is beautiful, light in weight and energy consumption is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

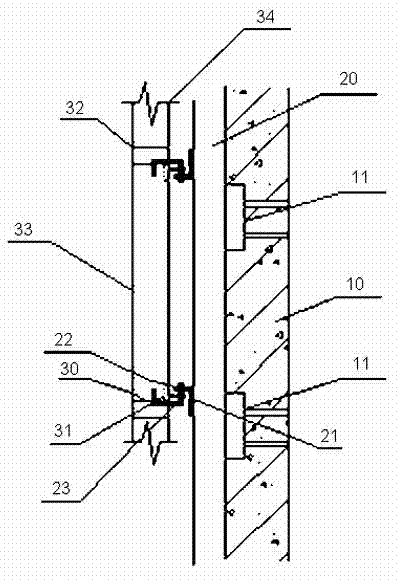

Image

Examples

preparation example Construction

[0031] Adopt the preparation method of thermosetting non-metallic composite art curtain wall thermal insulation board for architectural decoration of the present invention mainly comprises the following steps:

[0032] Step 1, kneading vinyl resin, inorganic fiber, aluminum hydroxide, initiator, curing agent and color paste into a mass mixed material according to the proportion;

[0033] Step 2, adding the above-mentioned mixed material to the metal mold of the curtain wall panel through an injection molding machine or a die-casting machine;

[0034] Step 3, heating the metal mold of the curtain wall panel to 120°C~180°C, so that the above-mentioned mixed material is heated and solidified in the mold;

[0035] Step 4, open the mold, and take out the formed curtain wall panel shell;

[0036] Step 5, loading or pressurizing into the above-mentioned shell a class A flame-retardant foam material, curing and molding at room temperature, to obtain a curtain wall insulation board; ...

Embodiment 1

[0039] The following raw materials by weight percentage:

[0040] Vinyl resin produced by Showa Polymer (Shanghai) Co., Ltd. 20%;

[0041] 20% wollastonite with aspect ratio of 20~40:1 produced in Qinghai;

[0042] Magnesium whiskers produced in Qinghai Salt Lake 10%;

[0043]Ultra-fine aluminum hydroxide produced by Japan Showa Electronics Co., Ltd. 48%;

[0044] Curing agent methyl ethyl ketone peroxide 1%;

[0045] The weight ratio of tert-butyl peroxybenzoate and benzoyl peroxide is 1:2 initiator 1%;

[0046] Fully mix and stir the above-mentioned raw materials in the mixer according to the above-mentioned formula quantity, fill the mixed raw materials into the barrel of the injection molding machine, and use the injection molding machine to inject the composite material in the barrel into the metal mold of the curtain wall panel; The metal mold of the panel is heated to 120 ° C ~ 180 ° C, so that the composite material is heated and solidified in the mold; open the mo...

Embodiment 2

[0049] The following raw materials by weight percentage:

[0050] Vinyl resin produced by Showa Polymer (Shanghai) Co., Ltd. 30%;

[0051] 25% wollastonite with aspect ratio of 20~40:1 produced in Qinghai;

[0052] 45% superfine aluminum hydroxide produced by Japan Showa Electronics Co., Ltd.;

[0053] Curing agent methyl ethyl ketone peroxide 2%;

[0054] The weight ratio of tert-butyl peroxybenzoate and benzoyl peroxide is 1:2 initiator 1%;

[0055] Color paste 2%;

[0056] According to the above formula, the above raw materials are fully mixed and stirred in the mixer, and after drying, the mixed raw materials are added to the metal mold of the curtain wall panel through a die-casting machine; the metal mold of the curtain wall panel is heated to 120 ℃ ~ 180 ℃, heat and solidify the composite material in the mold; open the mold, take out the molded curtain wall panel shell with a box-like structure; pressurize and inject inorganic phase change foam material into the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Barcol hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com