Nano-reinforced water-based acrylic modified epoxy bottom surface integrated anti-corrosion baking paint coating and preparation method thereof

A water-based acrylic and modified technology, used in the field of coatings, can solve the problems of poor solvent resistance and decoration, environmental and human harm, and achieve the effect of reducing construction technology, non-yellowing coating film, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

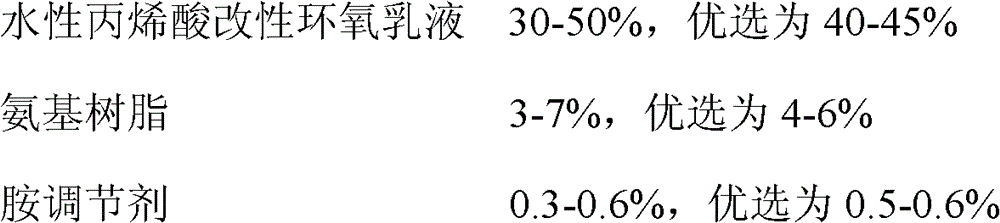

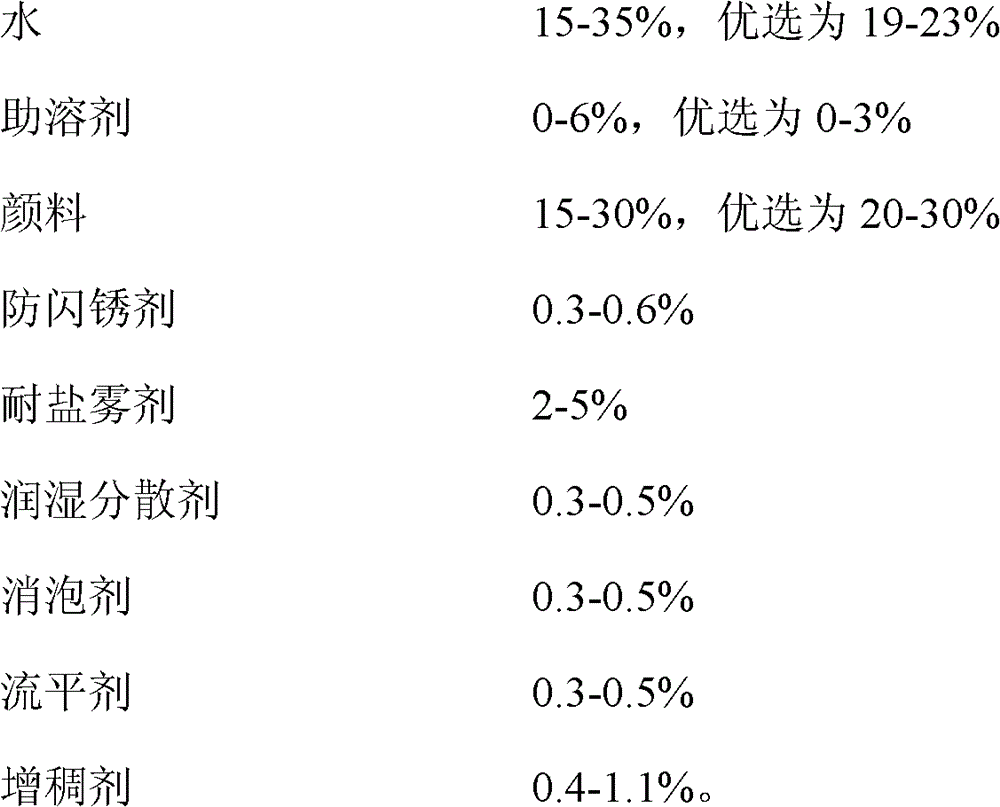

[0029] The purpose of the present invention is to provide a nano-reinforced water-based acrylic modified epoxy bottom surface that is easy to use, beneficial to environmental protection, excellent in mechanical properties, excellent in corrosion resistance, good in decoration, and capable of fast curing (only 30s at 220°C) An all-in-one anti-corrosion baking varnish coating and a preparation method thereof. The present invention improves the prior art, and provides a water-based acrylic modified epoxy bottom surface integrated anti-corrosion baking varnish coating, which comprises the following raw material components in terms of weight percentage: 30-50% of water-based acrylic modified epoxy emulsion, Amino resin 3-7%, amine regulator 0.3-0.6%, water 15-35%, cosolvent 0-6%, pigment 15-30%, anti-flash rust agent 0.3-0.6%, salt spray resistance 2-5% %, wetting and dispersing agent 0.3-0.5%, defoamer 0.3-0.5%, leveling agent 0.3-0.5% and thickener 0.4-1.1%

[0030] Each compone...

Embodiment 1

[0055] Embodiment 1: Synthetic method of water-based acrylic acid modified epoxy emulsion

[0056] The formula of water-based acrylic modified epoxy emulsion is:

[0057] Epichlorohydrin 29.4kg (29.4%)

[0058] Bisphenol A46.2kg (46.1%)

[0059] Butyl acrylate 10kg (10%)

[0060] Methyl methacrylate 10kg (10%)

[0061] Dimethylethanolamine vinylbenzenesulfonate 1.2kg (1.2%)

[0062] Styrene 3kg (3%)

[0063] Initiator Epoxy-M 0.3kg (0.3%)

[0064] Preparation:

[0065] (8) Take 0.3% initiator, vacuumize at 0-5° C.-fill with nitrogen for 10 cycles, and seal with nitrogen;

[0066] (9) Add 2% styrene and 10% butyl acrylate, mix and stir, and irradiate for 1 hour with a 150W ultraviolet lamp (200-400nm) broad band under vertical irradiation at a distance of 10cm;

[0067] (10) Add 10% methyl methacrylate and irradiate for 1 hour;

[0068] (11) Add 1.2% vinylbenzenesulfonic acid dimethylethanolamine salt (the molar ratio of vinylbenzenesulfonic acid and dimethylethanolami...

Embodiment 2

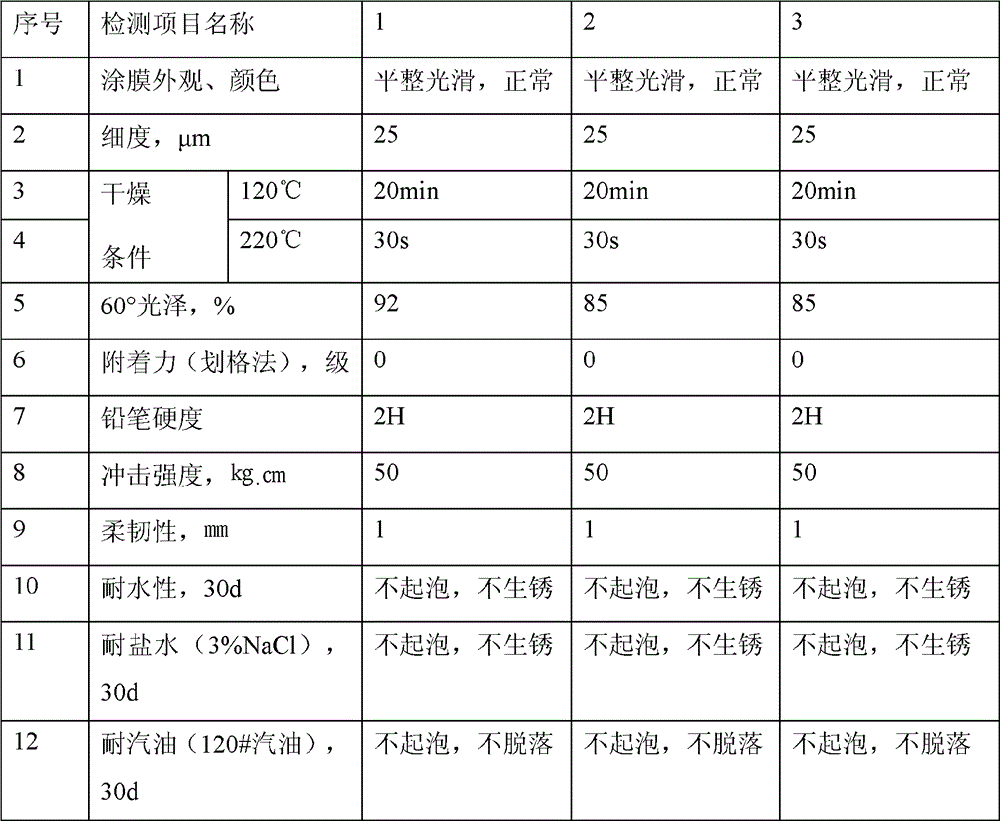

[0076] The formula of one-component water-based acrylic modified epoxy bottom-surface-integrated anti-corrosion baking paint is:

[0077] Water-based acrylic modified epoxy emulsion (self-made) 45kg (45%)

[0078] Amino resin (Cymel303, cyanotech Co., Ltd.) 5.4kg (5.4%)

[0079] Amine regulator (DMEA, BASF Applied Chemicals Co., Ltd.) 0.5kg (0.5%)

[0080] Tap water 20kg (20%)

[0081] Cosolvent (benzyl alcohol, Shenzhen Jiadida Chemical Co., Ltd.) 3kg (3%)

[0082] Wetting and dispersing agent (PE-100, Shenzhen Haichuan Chemical Co., Ltd.) 0.4kg (0.4%)

[0083] Defoamer (BYK-020, BYK Chemical Company) 0.3kg (0.3%)

[0084] Leveling agent (Levaslip W-409, Elements Special Chemicals) 0.3kg (0.3%)

[0085] Thickener (TT-935, Rohm and Haas Co., Ltd.) 0.6kg0.6%)

[0086] Anti-flash rust agent (CT-08 of Shanghai Citong New Material Company) 0.5kg (0.5%)

[0087] Salt spray resistance agent (CTP-606 of Shanghai Citong New Material Co., Ltd.) 3kg (3%)

[0088] Iron oxide red ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com