Amphiphilic graphene oxide and preparation method thereof and application in waterborne coating thereof

A technology of water-based coatings and stone oxide, which is applied in the direction of epoxy resin coatings, chemical instruments and methods, anti-corrosion coatings, etc., can solve problems such as the limitation of graphene oxide, and achieve the effects of slowing down agglomeration, increasing interlayer spacing, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method for amphiphilic graphene oxide, comprising the steps of:

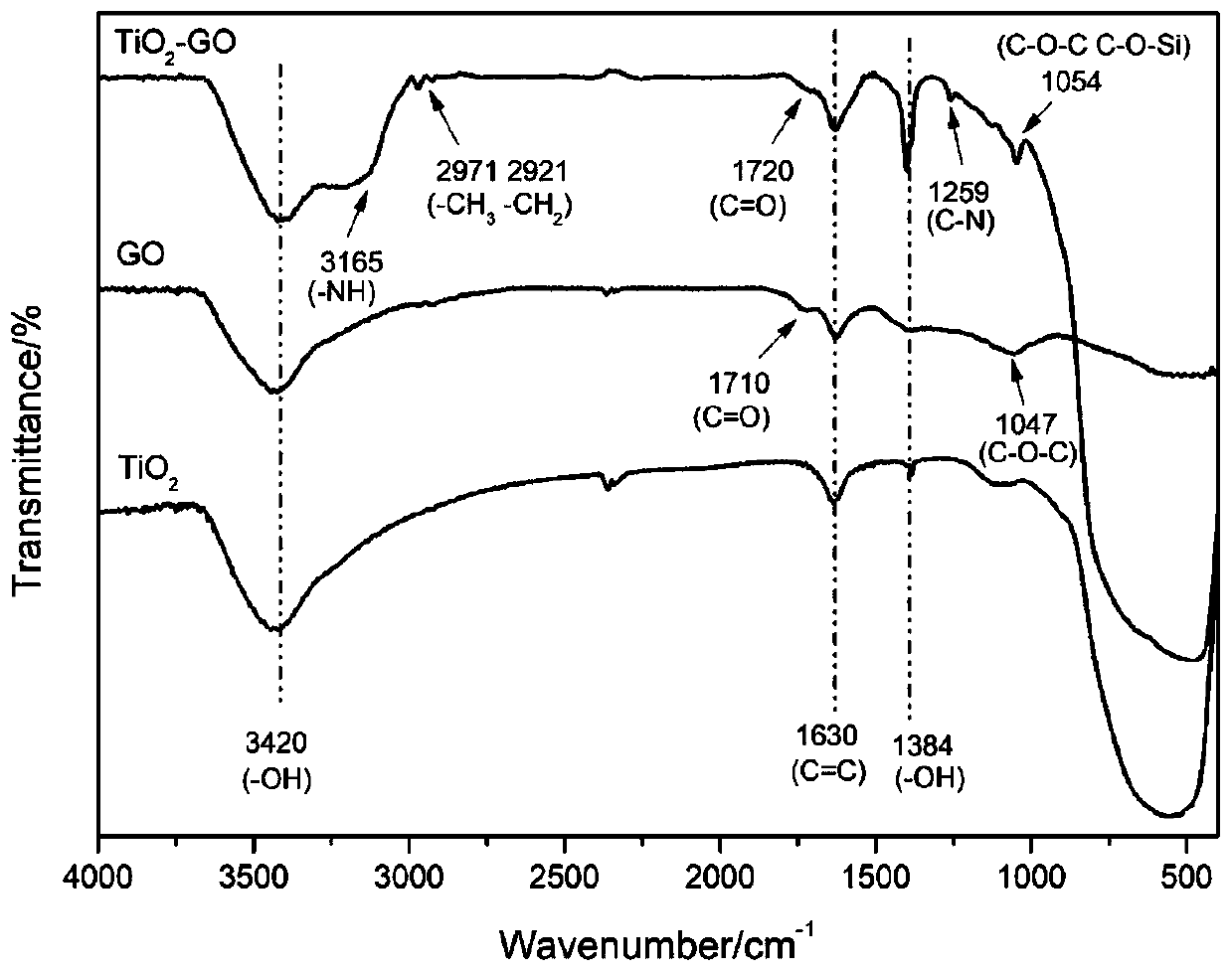

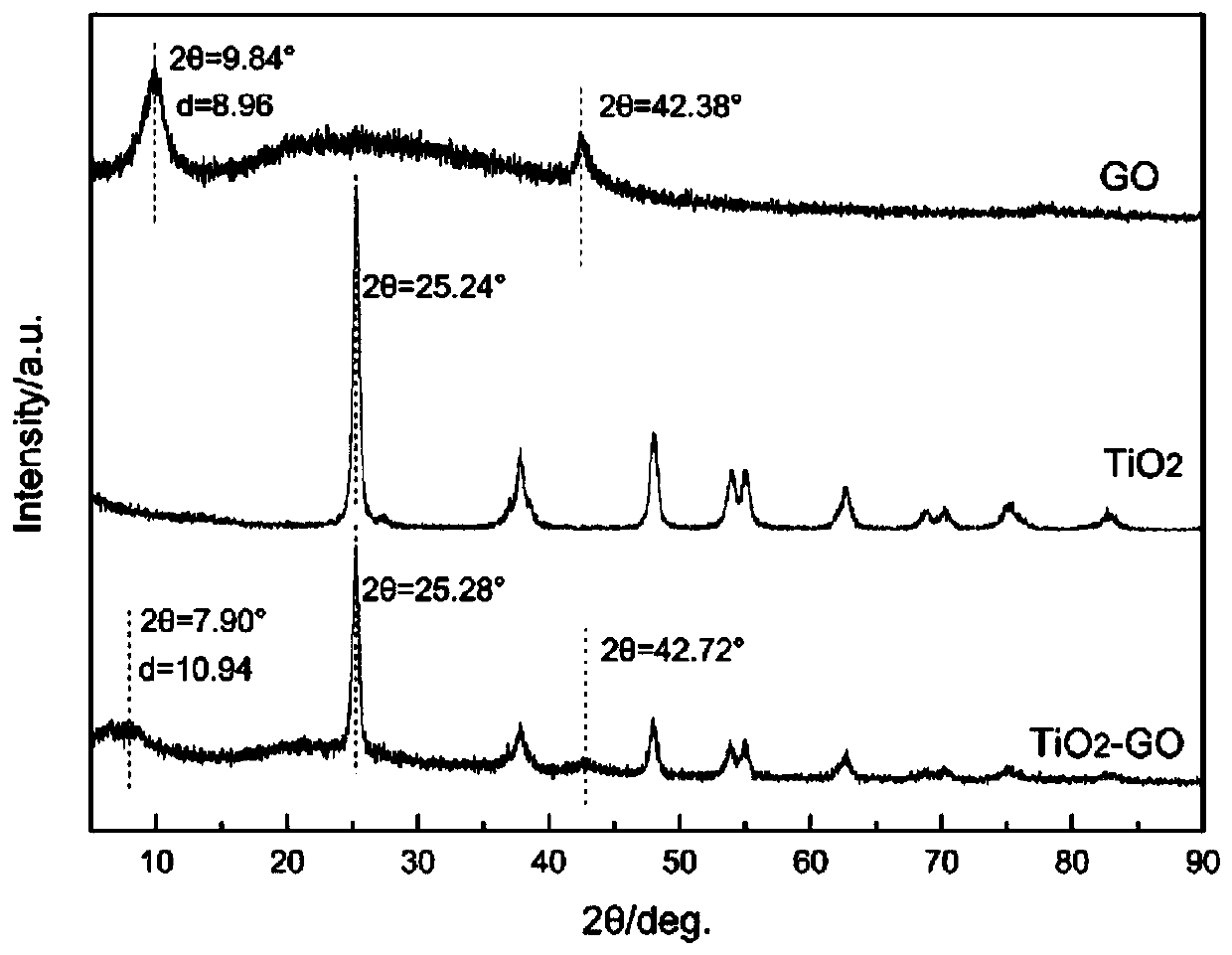

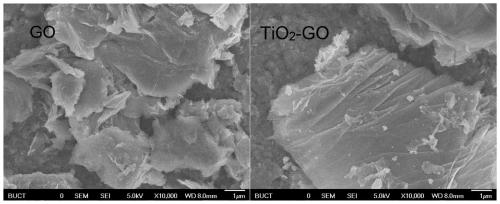

[0052] (1) Weigh 1g of 3-isocyanatopropyltrimethoxysilane into a clean dry beaker, add 0.1g of graphene oxide, seal the mouth of the beaker with a safety film to prevent air from entering, sonicate for 20min; then add 50ml of N, N -Dimethylformamide, then heated in an oil bath (105°C) and stirred magnetically for 2 hours, then centrifuged to remove the supernatant, washed the obtained solid product with ethanol for 3 times, and put it into liquid nitrogen to freeze for 10 minutes to ensure that the product was frozen After being applied, freeze-dry for 72 hours to obtain modified graphene oxide;

[0053] (2) Add the modified graphene oxide prepared in step (1) to 25ml of ethanol to make an alcoholic solution, ultrasonic 20min, and set aside;

[0054] (3) Weigh 0.03g nano-TiO 2 Add 25ml deionized water to make TiO 2 Aqueous solution, ultrasonic 20min, standby;

[0055] (4) In the case of ...

Embodiment 2

[0057] A preparation method for a water-based paint, comprising the steps of: adding the amphiphilic graphene oxide prepared in Example 1 to the water-based epoxy resin paint and stirring evenly, the addition of the amphiphilic graphene oxide is 0.1% of the water-based paint quality. %; then add the curing agent (F705), the mass ratio of the water-based epoxy resin to the curing agent is 1:2, then add the auxiliary agent, stir evenly, to obtain final product; the auxiliary agent includes: wetting agent BYK-348 , dispersant DISPERBYK-2062, leveling agent BYK-381, defoamer BYK-021, each added in an amount of 0.05wt% of the water-based paint mass.

Embodiment 3

[0059] A preparation method for water-based paint, comprising the steps of:

[0060] (1) Weigh 1.5g of 3-isocyanatopropyltrimethoxysilane into a cleaned dry beaker, add 0.13g of graphene oxide, seal the mouth of the beaker with a safety film to prevent air from entering, ultrasonic for 25min; then add 60ml of N, N-dimethylformamide, then heated in an oil bath (100°C) and stirred magnetically for 2.5 hours, then centrifuged to remove the supernatant, washed the obtained solid product with ethanol for 5 times, and put it into liquid nitrogen to freeze for 10 minutes to ensure After the product is frozen, freeze-dry for 75 hours to obtain modified graphene oxide;

[0061] (2) Add the modified graphene oxide prepared in step (1) to 35ml of ethanol to make an alcoholic solution, ultrasonic 15min, and set aside;

[0062] (3) Weigh 0.03g nano-TiO 2 Add 25ml deionized water to make TiO 2 Aqueous solution, ultrasonic 15min, standby;

[0063] (4) In the case of magnetic stirring, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com