High-frequency radar level meter capable of sweeping dust

A radar level meter and high-frequency technology, which is applied in the direction of engine lubrication, cleaning methods and tools, cleaning methods using tools, etc., can solve problems such as complex operation, hidden safety hazards in the cleaning process, frequent cleaning operation cycles, etc., to achieve Improved measurement accuracy and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

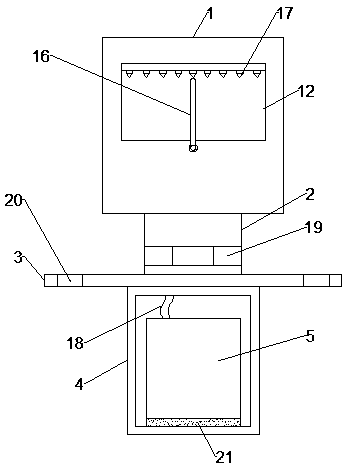

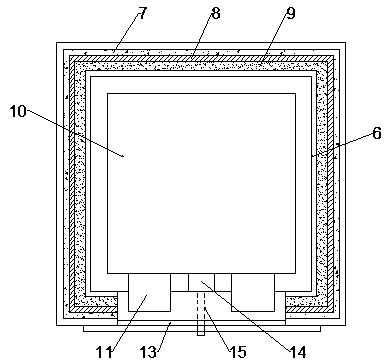

[0023] Such as Figure 1-2 As shown, the high-frequency radar level gauge according to the embodiment of the present invention includes an outer shell 1, the bottom end of the outer shell 1 is provided with a connecting body 2, and the bottom end of the connecting body 2 is provided with a flange 3, The bottom end of the flange 3 is provided with a box body 4, the inside of the box body 4 is provided with an air source 5, the inside of the outer casing 1 is provided with an inner casing 6, and the inner casing 6 is connected to the An anti-corrosion layer 7, a strength layer 8 and an anti-seismic filling layer 9 are sequentially arranged between the outer casing 1, and a radar level gauge body 10 is arranged inside the inner casing 6, and the radar level gauge body 10 One end is provided with a plurality of detection heads 11, and the outer casing 1 and the inner casing 6 are respectively provided with detection windows 12 on the sides close to the detection heads 11, and the ...

Embodiment 2

[0028] Such as Figure 1-2 As shown, the connecting body 2 and the flange 3 are connected through bolts 19, and the flange 3 is provided with a number of installation holes 20, and the connection between the air source 5 and the box 4 A buffer pad 21 is arranged between them, the rotation angle of the cleaning rod 16 is 270 degrees, the anti-corrosion layer 7 is made of epoxy resin, the strength layer 8 is made of carbon fiber, and the shock-resistant filling layer 9 is made of rubber.

[0029] From figure 1 It can be seen from the figure that the connecting body 2 and the flange 3 are connected through bolts 19, and the flange 3 is provided with a number of installation holes 20, and the gas source 5 and the box body 4 is provided with a buffer pad 21, the design of the bolt 19, the mounting hole 20 and the buffer pad 21 is relatively conventional, so no detailed description will be given.

[0030] In order to facilitate the understanding of the above-mentioned technical so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com