Production method of cellulose non-woven fabric with functions of mildew proofing, antibiosis and deodorization through wet-type meltbrown

A technology of cellulose and natural cellulose, applied in the direction of single-component cellulose rayon, wet spinning, non-woven fabrics, etc., can solve the problems of natural environment decomposition, environmental adverse impact, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment one (i.e. sample number 1~12 of the present invention):

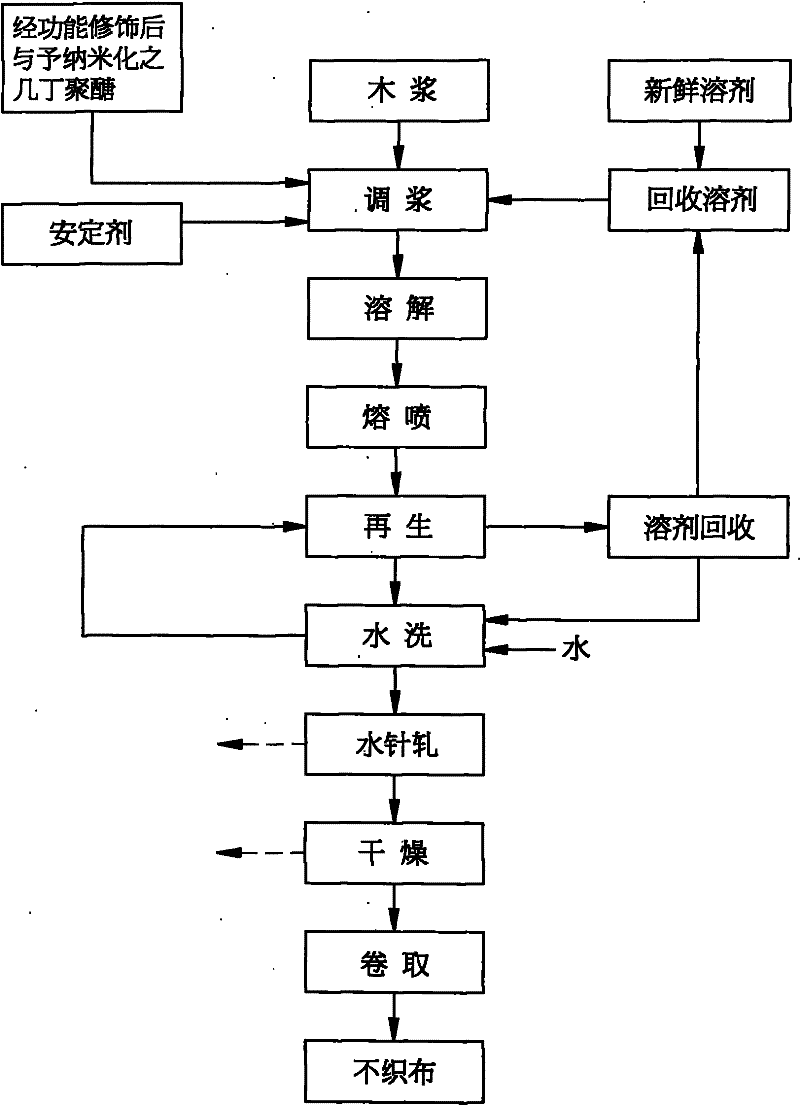

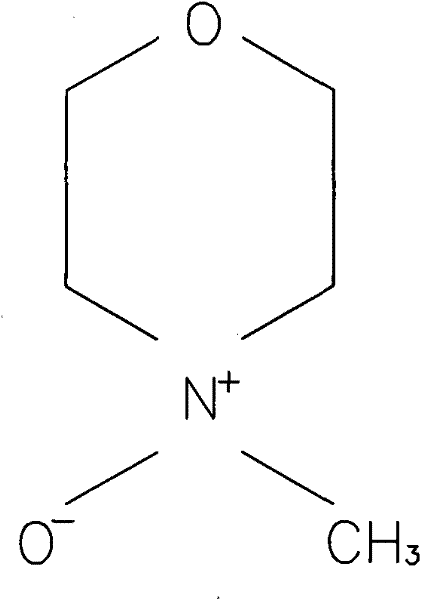

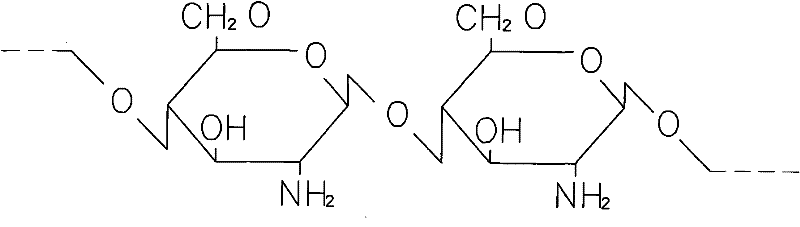

[0047] Take wood pulp cellulose with a degree of polymerization of 650 and add chitosan macromolecule (chitosan) with a degree of deacetylation of 87% and 95% after functional modification and nanonization, accounting for 0.1wt% to 5.0wt% of the fiber , mixed with the solvent oxidized methyl marin in a good proportion of the slurry, and then use a vacuum thin film evaporator to evaporate the excess water, heat at 80°C to 120°C, and remove the water to 5% to 13% within 5 minutes, then the Cellulose dissolves into mucus (dope), and the composition of mucus is shown in Table 1. Then the mucus is sent to the melt-blown machine with a metering pump for melt-blowing, sprayed out through the spinning nozzle to form a non-woven mesh, solidified with water mist and regenerated, and then washed with water, water-needled, dried and coiled to complete the process in Table 1. Table of each mucus composition of sam...

Embodiment 2

[0051] Embodiment two (i.e. sample number 13~24 of the present invention):

[0052] Take wood pulp cellulose with a degree of polymerization of 1050 and add chitosan macromolecule (chitosan) with a degree of deacetylation of 87% and 95% after functional modification and nanotechnology, accounting for 0.1wt% to 5.0wt% of the fiber , mixed with the solvent oxidized methyl marin in a good proportion of the slurry, and then use a vacuum thin film evaporator to evaporate the excess water, heat at 80°C to 120°C, and remove the water to 5% to 13% within 5 minutes, then the Cellulose dissolves into mucus (dope), and the composition of mucus is shown in Table 2. The slime is sent to the melt-blown machine with a metering pump for melt-blowing. The melt-blown nonwoven fabric is regenerated in a coagulation bath, and then washed with water, needle-rolled, dried and coiled to complete the slimes of samples 13 to 24 in Table 2. Composition table.

[0053] Table 2 The mucus composition of...

Embodiment 3

[0055] Embodiment 3 (evaluation of anti-mold function):

[0056] The evaluation of the anti-mold function uses Staphylococcus aureus subsp.Aureus 10451 as the test strain, and the number of bacteria is first cultivated to 5-70E +5 (number of bacteria / milliliter), get 0.2ml of test bacterium liquid and spread evenly on the sample of 0.2g, place in a sterilized capped sample bottle, and cultivate at 35°C for 18 hours. Then add 20ml of sterilized buffered saline, shake vigorously for 30 times, let the test bacteria disperse in the solution, take the solution after appropriate dilution, take 1ml for agar broth culture, the culture condition is 35°C for 48 hours, and then count the colonies The number of growth, and finally the number of bacteria on the sample can be calculated according to the dilution factor and volume. The above experiment was repeated 6 times. After calculating the average number of total bacteria, the anti-mold effect of the sample can be judged according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com