A unilateral prestressed fully assembled self-resetting steel frame joint

A prestressed, fully assembled technology, applied in protective buildings/shelters, building types, buildings, etc., can solve problems such as weakening columns, and achieve the effects of reducing risk, reducing labor costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific examples, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the protection scope of the present invention.

[0031] In the present invention, unless stated otherwise, the used orientation words such as "upper and lower" usually refer to the definition based on the drawings of the corresponding drawings, and "inner and outer" refer to the contours of the corresponding parts. inside and out.

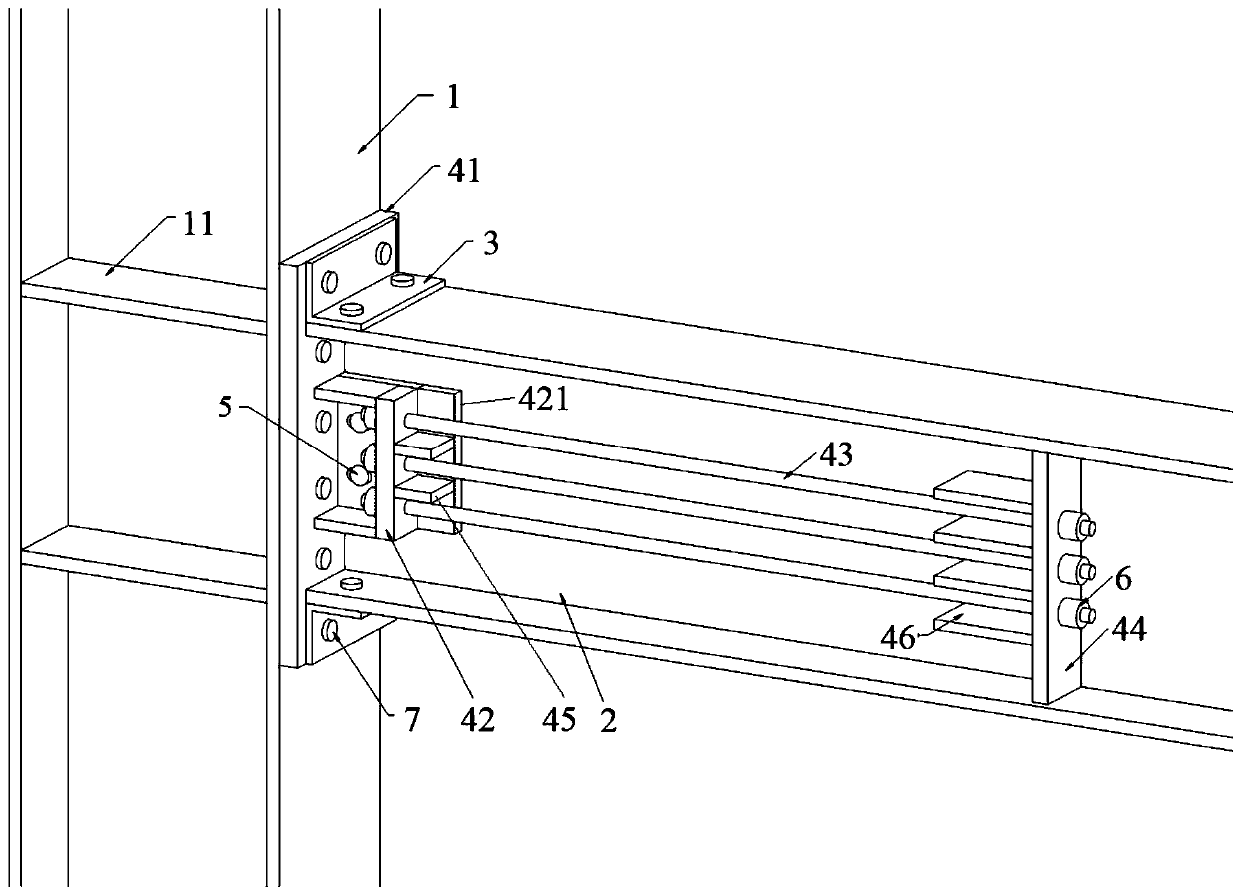

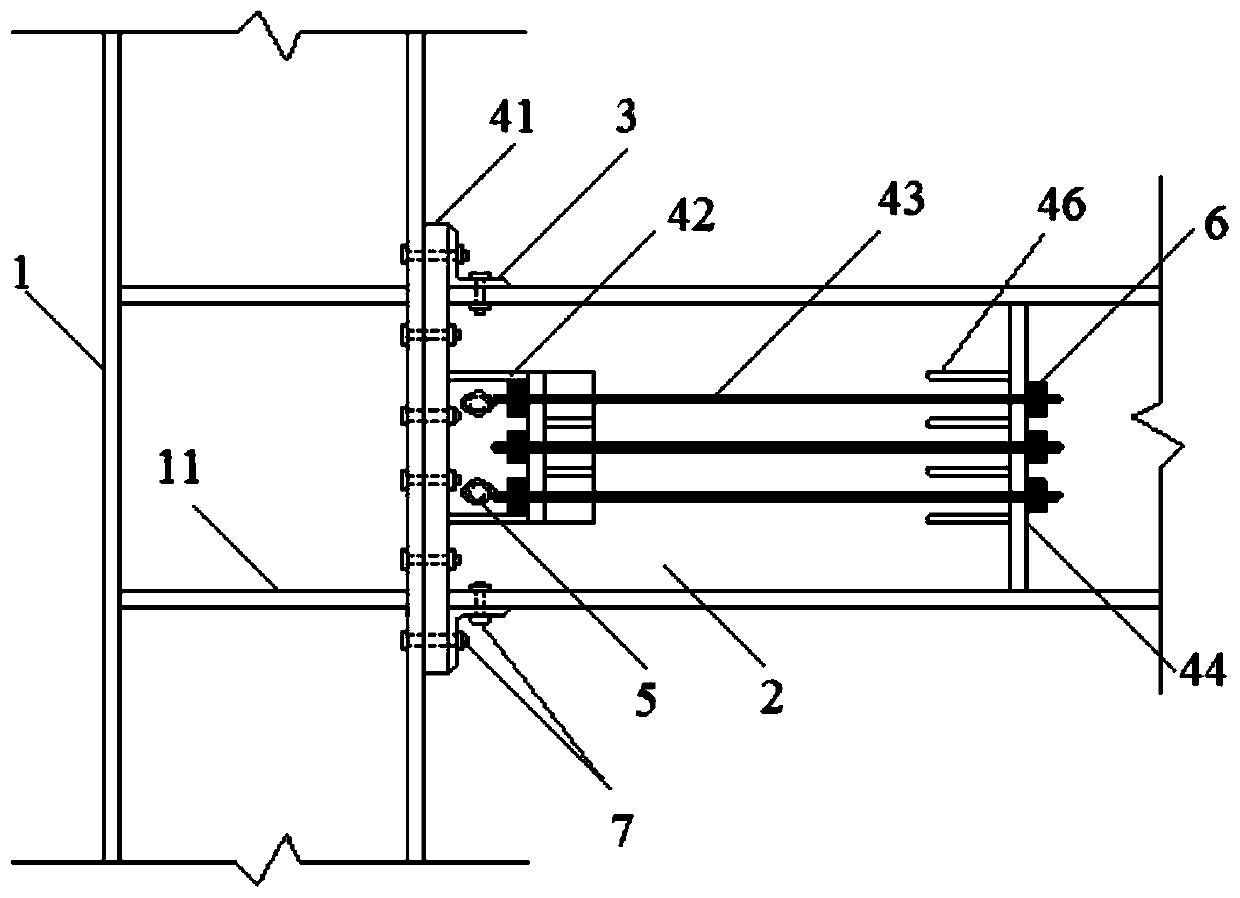

[0032] Such as figure 1 and 2 As shown, the present invention discloses a unilateral prestressed fully assembled self-resetting steel frame node, including H-shaped steel columns 1, H-shaped steel beams 2, energy-dissipating parts 3 and connecting parts, the connecting parts include end plates 41, grooves Type connector 42, prestressed steel strand 43 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com