Auxiliary jig for manipulator

A technology of manipulators and fixtures, applied in manipulators, manufacturing tools, metal processing, etc., can solve the problems of product quality, unequipped parts of products, parts easily stuck in sockets, etc., to ensure product quality and complete assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

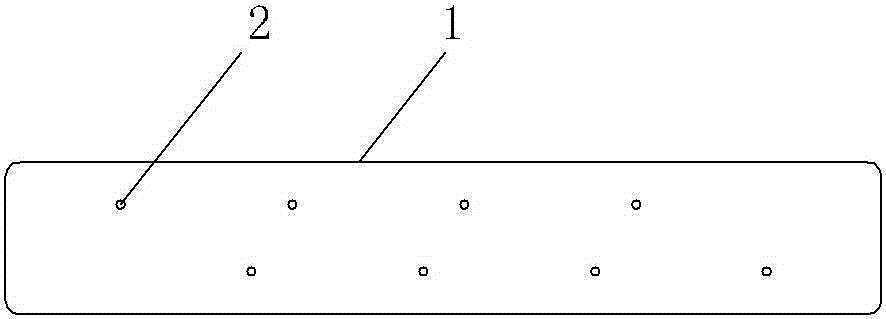

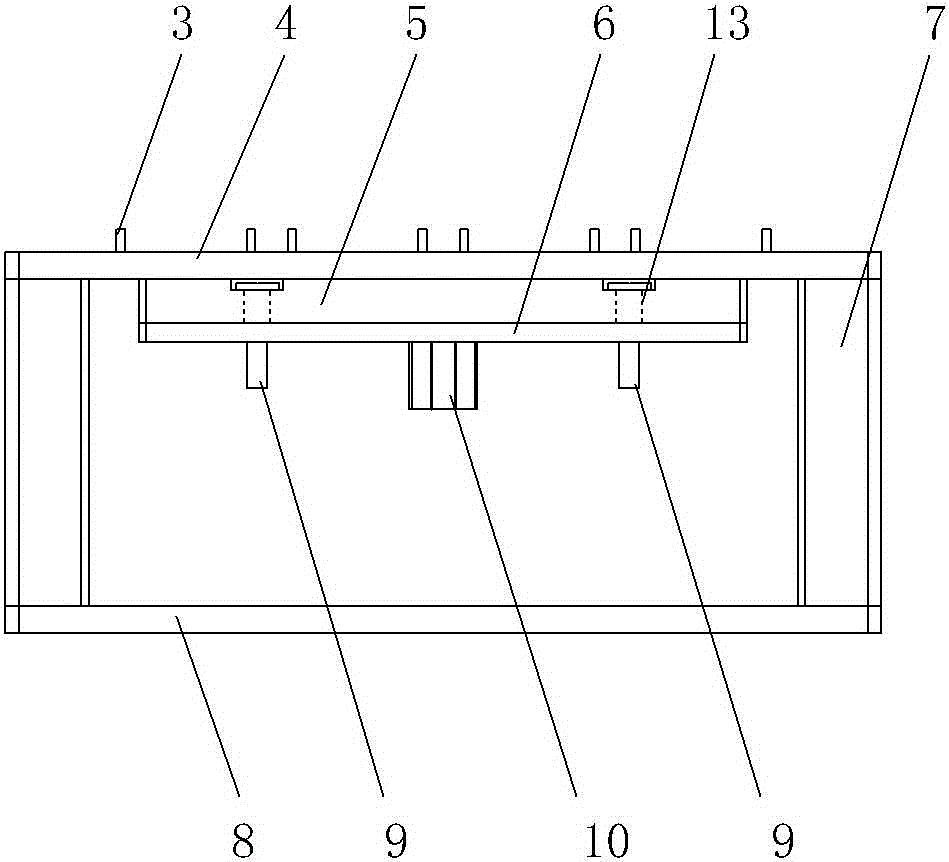

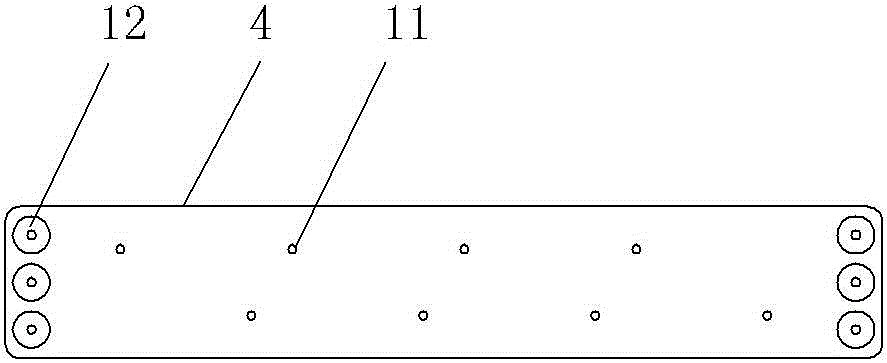

[0013] Such as figure 2 and image 3 As shown, the auxiliary jig for the manipulator includes a mounting plate. The mounting plate 4 has a socket 11, and also includes a bracket and an ejection structure. The bracket includes a support block 7 and a bottom plate 8. Side, the lateral sides of the mounting plate 4 are fixed on the two support blocks 7 of the bracket, the socket 11 is a perforation through the mounting plate 4, the ejection structure includes the top plate and the lifting drive device 10, and the lifting drive device 10 is installed on the bottom plate 8 , the top plate is fixedly connected to the output end of the lifting drive device 10, the top plate is located directly below the mounting plate 4, and is provided with a thimble 3 facing the jack, the thimble 3 moves up and down in the jack through the drive of the lifting drive device, The top plate includes a drive plate 6 and a fixed plate 5, the drive plate 6 is fixedly connected to the output end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com