Method for template-free hydrothermal synthesis of one-dimensional nano-Bi2Fe4O9

A bi2fe4o9, hydrothermal synthesis technology, applied in chemical instruments and methods, inorganic chemistry, iron compounds, etc., can solve the problems of harsh experimental environment, high reaction temperature, and precise control of reaction pH, achieving feasibility and controllability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

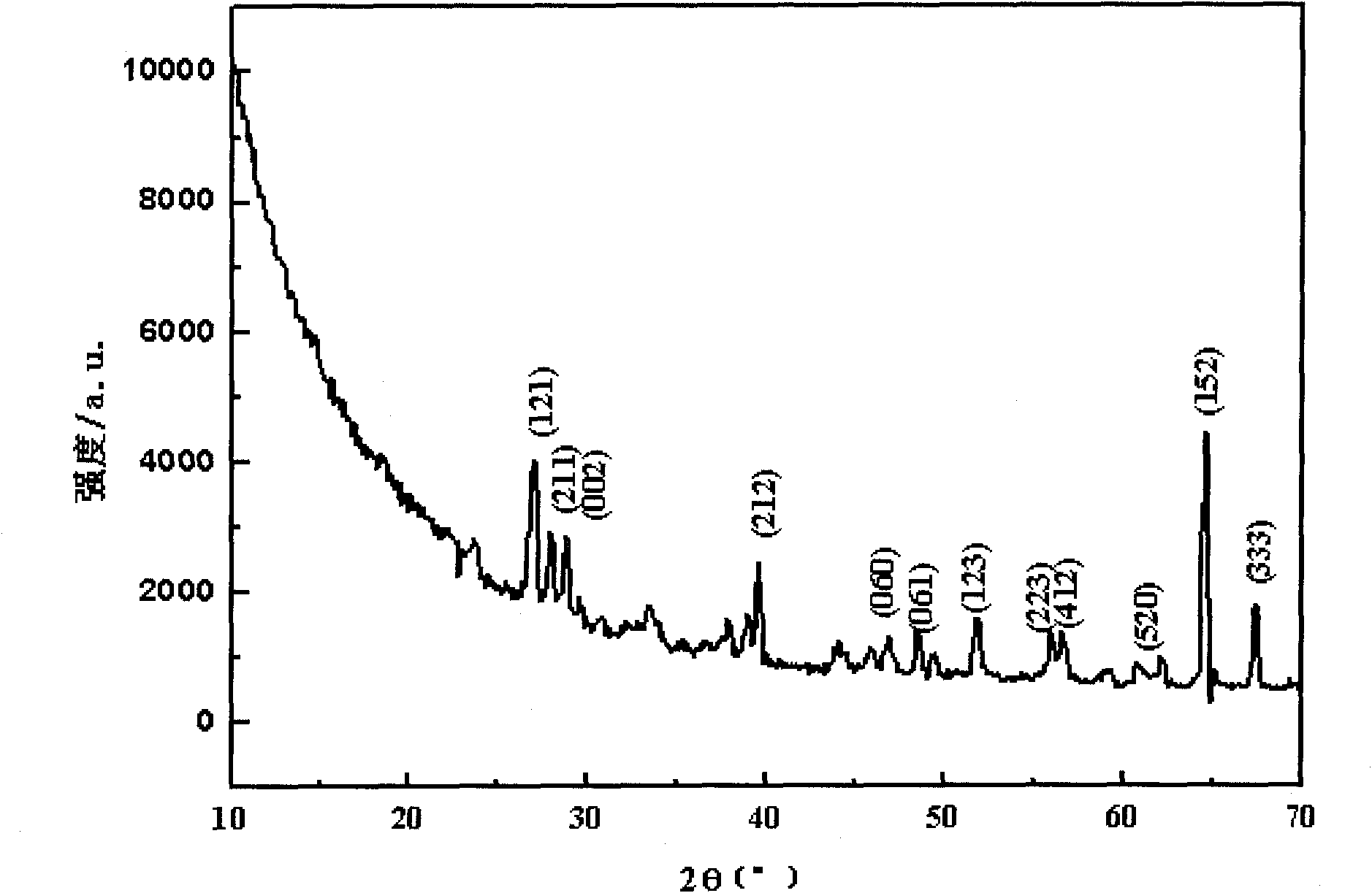

[0029] Bi(NO 3 ) 3 ·5H 2 O (1.94 g) and Fe (NO 3 ) 3 9H 2 O (1.616 g) was dissolved in 0.1 normal concentration of nitric acid, then titrated with 12 mol / L NaOH solution until the precipitation was complete, then filtered and washed with water until the solution was neutral, and the Na in it was also washed away. + and NO 3 -. The precipitate that is obtained is dissolved in the NaOH solution that concentration is 8 mol / liter, is made into 40 milliliters of solutions; Bi(NO 3 ) 3 ·5H 2 The concentration of O is 100 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 100 mmol / L, quickly pour it into a 50 ml reaction kettle and add a titanium sheet, place it in an oven at 160°C for 72 hours, take out the titanium sheet and rinse it with deionized water and alcohol, and put it in an oven at 60°C After 4 hours, the final product obtained on the titanium sheet is one-dimensional nano-Bi 2 Fe 4 o 9 crystals.

Embodiment 2

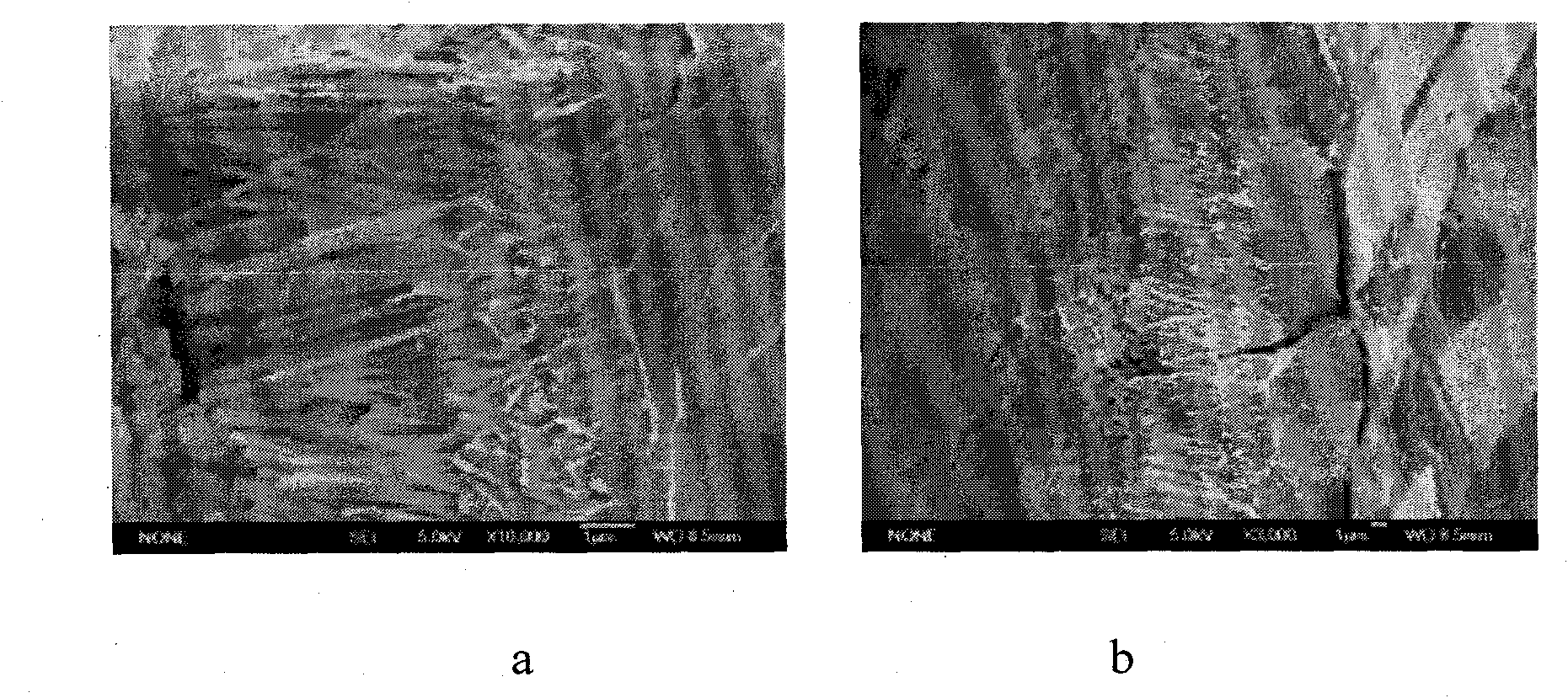

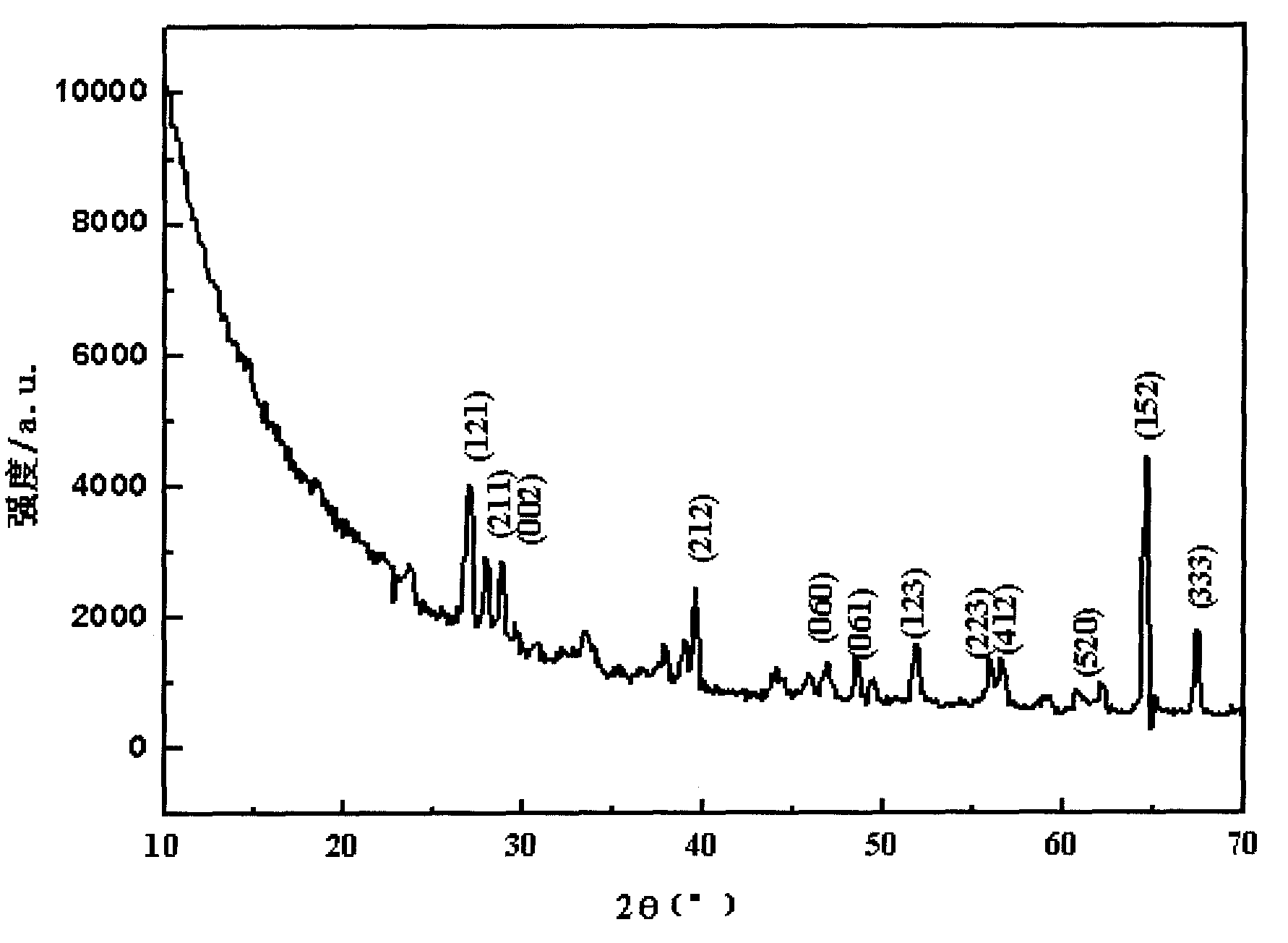

[0031] Equivalent amount of Bi(NO 3 ) 3 ·5H 2 O (970 mg) and Fe (NO 3 ) 3 9H 2 O (808 mg) was dissolved in dilute nitric acid of 0.1 normal concentration, then titrated with 12 mol / L of NaOH until the precipitation was complete, then filtered and washed with water until the solution was neutral, and the Na was also washed away. + and NO 3 - . The precipitate obtained is dissolved in a NaOH solution with a concentration of 20 mol / liter to make 40 milliliters of solution, Bi(NO 3 ) 3 ·5H 2 The concentration of O is 50 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 50 mmol / L, quickly pour it into a 50 ml reaction kettle and add a titanium sheet, place it in an oven at 180°C for 50 hours, take out the titanium sheet and rinse it with deionized water and alcohol, and put it in an oven at 100°C After 2 hours, the final product obtained on the titanium sheet is highly oriented growth nanosheet Bi 2 Fe 4 o 9 . Flake Bi 2 Fe 4 o 9 One-dimensional nano-Bi growth ...

Embodiment 3

[0033] Equivalent amount of Bi(NO 3 ) 3 ·5H 2 O (232.8 mg) and Fe (NO 3 ) 3 9H 2 O (193.9 mg) was dissolved in 0.1 normal concentration of dilute nitric acid, then titrated with 12 mol / L of NaOH until the precipitation was complete, then filtered and washed with water until the solution was neutral, and the Na was also washed away. + and NO 3 - . The precipitate that is obtained is dissolved in the NaOH solution that concentration is 12 mol / liter, is made into 40 milliliters of solutions, Bi(NO 3 ) 3 ·5H 2 The concentration of O is 12 mmol / L, Fe(NO 3 ) 3 9H 2 The concentration of O is 12 mmol / L, quickly pour it into a 50 ml reaction kettle and add a titanium sheet, place it in an oven at 220°C for 50 hours, take out the titanium sheet and rinse it with deionized water and alcohol, and put it in an oven at 80°C After 4 hours, the final product obtained on the titanium sheet is highly oriented growth nanosheet Bi 2 Fe 4 o 9 . Flake Bi 2 Fe 4 o 9 One-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com