Method for synthesizing silicalite-1 zeolite membranes

A synthetic method and technology of molecular sieves, applied in the direction of molecular sieve compounds, molecular sieves and base exchange compounds, chemical instruments and methods, etc., to achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The aluminum oxide with a thickness of 2 mm and a diameter of 20 mm is used as a carrier, its porosity is 45%, and the average diameter of the void is 0.2 μm. Carrier pretreatment: smooth one side of the carrier with 1000-mesh sandpaper, ultrasonic cleaning, and dry at 40°C for two days. stand-by.

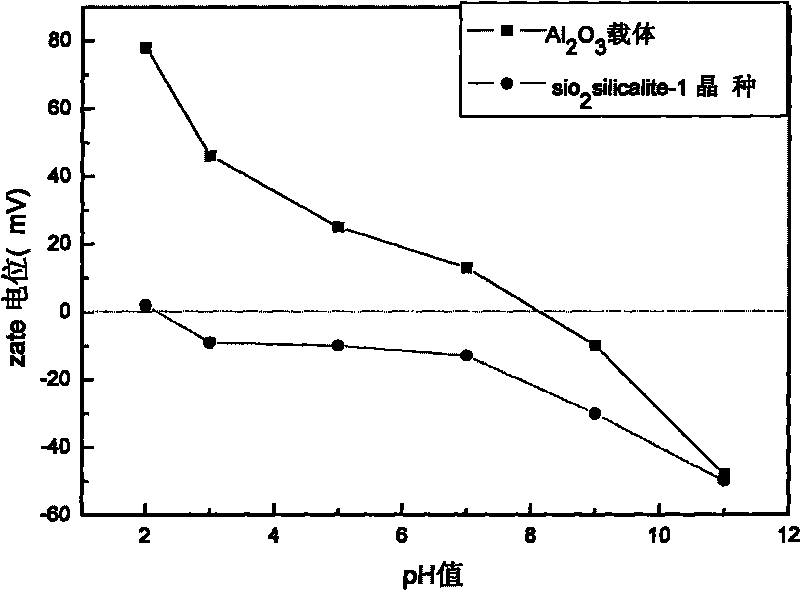

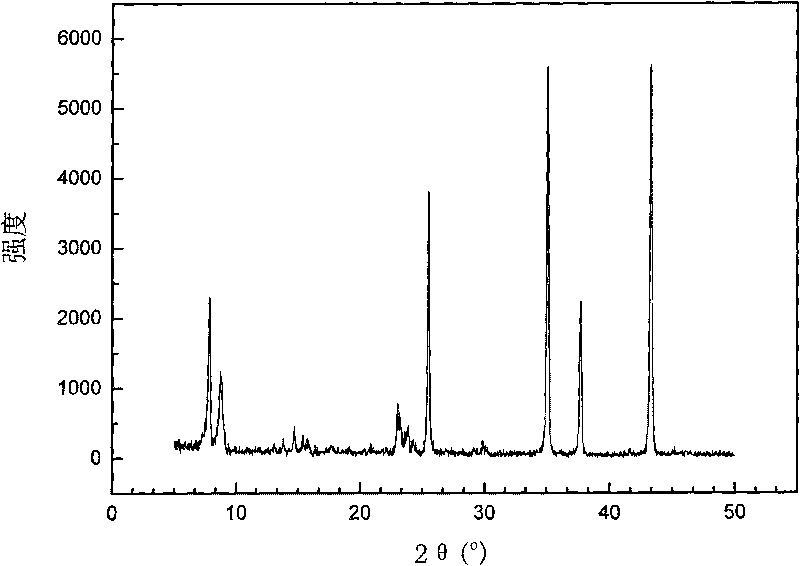

[0029] Put the TPAOH (1M) solution in a sealable polytetrafluoroethylene conical flask, and dissolve sodium hydroxide in the solution, heat to 80°C, and at 500rpm, put the fumed silica at a speed of 0.2g per minute This was added in portions to the solution to give a clear solution in the ratio 1 g (silica): 5 ml (TPAOH): 0.7 g (sodium hydroxide). Cool naturally to room temperature and age for 3 hours. Pour the synthesis liquid into a reaction kettle, conduct hydrothermal crystallization at 120° C. for 0.5 days, prepare the obtained seed crystals into a 10-50% solution, and adjust the pH value to about 10.

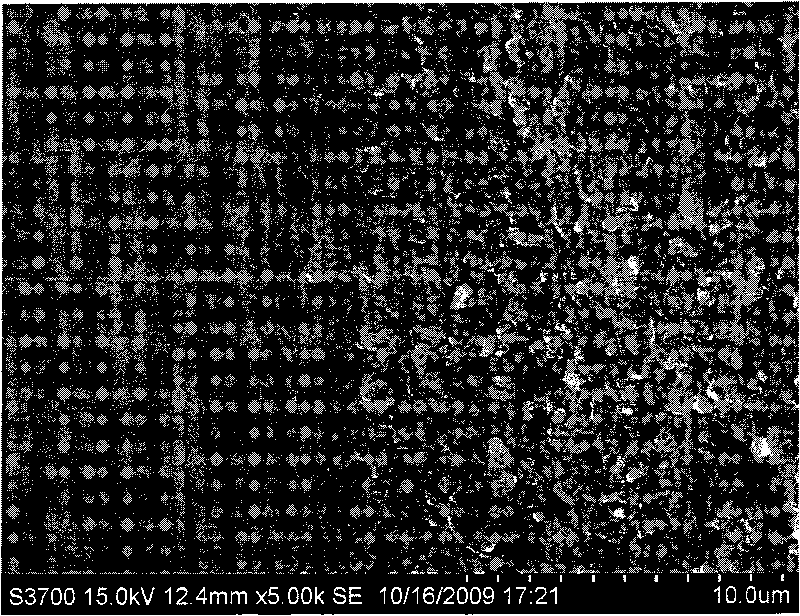

[0030] A small amount of the above seed crystal solution was tak...

Embodiment 2

[0033] In this experiment, aluminum oxide with a thickness of 2 mm and a diameter of 20 mm was used as a carrier, and its porosity was 45%, and the average diameter of the voids was 0.2 microns. Carrier pretreatment: smooth one side of the carrier with 1000-mesh sandpaper, ultrasonic cleaning, and dry at 40°C for two days. stand-by.

[0034] Put the TPAOH (1M) solution in a sealable polytetrafluoroethylene conical flask, and dissolve sodium hydroxide in the solution, heat to 80°C, and at 500rpm, put the fumed silica at a rate of 0.2g per minute This was added in portions to the solution to give a clear solution in the ratio 1 g (silica): 5 ml (TPAOH): 0.7 g (sodium hydroxide). Cool naturally to room temperature and age for 3 hours. Pour the synthesis solution into a reaction kettle, conduct hydrothermal crystallization at 120° C. for 1 day, prepare the obtained seed crystals into a 10-50% solution, and adjust its pH value to about 10.

[0035]A small amount of the above see...

Embodiment 3

[0038] In this experiment, aluminum oxide with a thickness of 2 mm and a diameter of 20 mm was used as a carrier, and its porosity was 45%, and the average diameter of the voids was 0.2 microns. Carrier pretreatment: smooth one side of the carrier with 1000-mesh sandpaper, ultrasonic cleaning, and dry at 40°C for two days. stand-by.

[0039] Put the TPAOH (1M) solution in a sealable polytetrafluoroethylene conical flask, and dissolve sodium hydroxide in the solution, heat to 80°C, and at 500rpm, put the fumed silica at a rate of 0.2g per minute This was added in portions to the solution to give a clear solution in the ratio 1 g (silica): 5 ml (TPAOH): 0.7 g (sodium hydroxide). Cool naturally to room temperature and age for 3 hours. Pour the synthesis solution into a reaction kettle, conduct hydrothermal crystallization at 120° C. for 2 days, prepare the obtained seed crystals into a 10-50% solution, and adjust its pH value to about 10.

[0040] A small amount of the above s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com