Template-free energy consumption steel plate shear wall and construction method thereof

A steel plate shear wall, no formwork technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of poor energy consumption performance, difficult construction, labor and time-consuming supporting formwork, etc., to enhance fire performance and reduce connection welding. Process, the effect of improving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

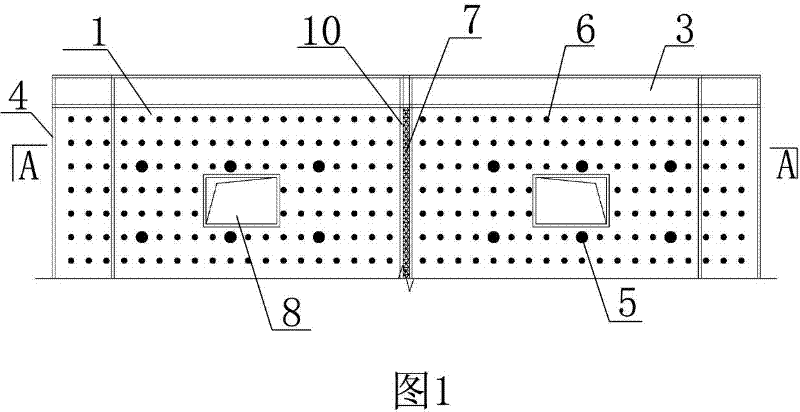

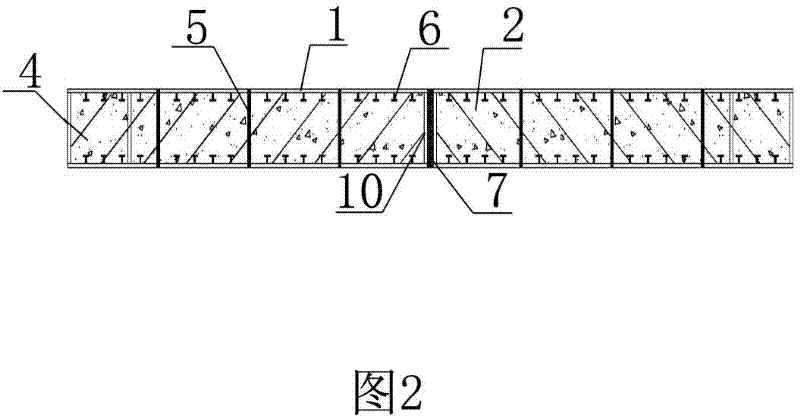

[0042] Embodiment one sees figure 1 and figure 2 As shown, a formwork-free energy-dissipating steel plate shear wall structure is composed of outer edge members and a body. The outer edge members include horizontal members 3 on the top and bottom of the body and vertical members 4 on the side of the body. The horizontal member 3 and the vertical member 4 are welded or bolted to the main body. The main body is composed of an inner core 2 and an outer cladding steel plate 1. The inner core 2 is sandwiched between mutually parallel outer cladding steel plates 1. The steel plates are tied by tension bolts 5, and vertical seams are reserved between the outsourcing steel plates 1 in the same plane, and the outsourcing steel plates are blocked by the sealing steel plates 10 at the vertical seams, and the power consumption is installed in the vertical seams. Part 7 can be connected. The vertical member 4 is a vertical plate or a column. The horizontal member 3 is a transverse stee...

Embodiment 2

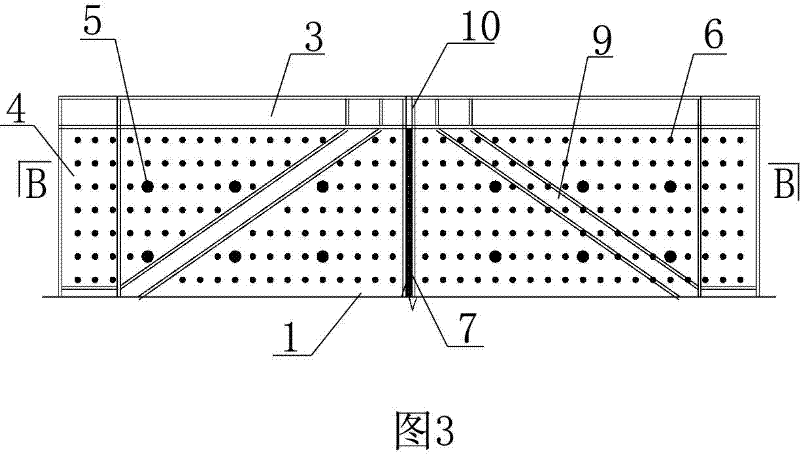

[0043] Embodiment two see image 3 and Figure 4 As shown, the difference from Embodiment 1 is that there is no opening on the body, and oblique stiffeners 9 are provided on the outer surface of the outer cladding steel plate.

Embodiment 3

[0044] Embodiment three see Figure 5 ~ Figure 7 As shown, the difference from the second embodiment is that there is no opening on the body, and the outer surface of the outer cladding steel plate is not provided with oblique stiffeners.

[0045] The specific implementation of the energy dissipation connector 7 can be found in Figure 8 to Figure 16 , Figure 8 The energy-dissipating connector 7 mentioned above is an energy-dissipating block 7.1 formed of filling material. Figure 9 The energy-dissipating connector 7 described in the above is an energy-dissipating block 7.1 formed of filling material, and the plugging steel plate 10 is welded with a stud B13. Figure 10 The energy-dissipating connecting piece 7 described in the above is an energy-dissipating block 7.1 formed of filling material, and a steel bar 15 is welded on the sealing steel plate 10 . The above-mentioned filling material is concrete, cement mortar, gypsum, lime or rubber, and fibers, steel bars or stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com