Superimposed assembled type underground pipe gallery system and construction and manufacturing process

An underground pipe gallery and prefabricated technology, used in artificial islands, water conservancy projects, underwater structures, etc., can solve the problems of low production efficiency and small transportation volume, and achieve low production efficiency, low workload and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

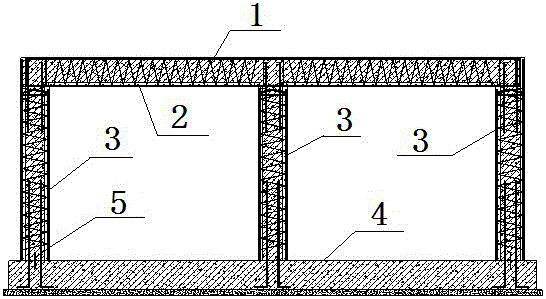

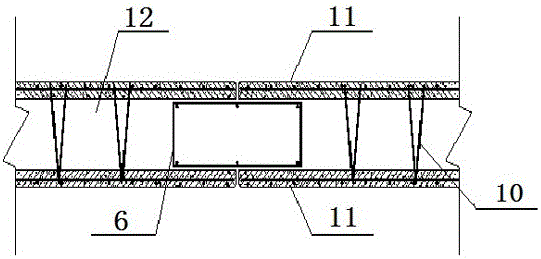

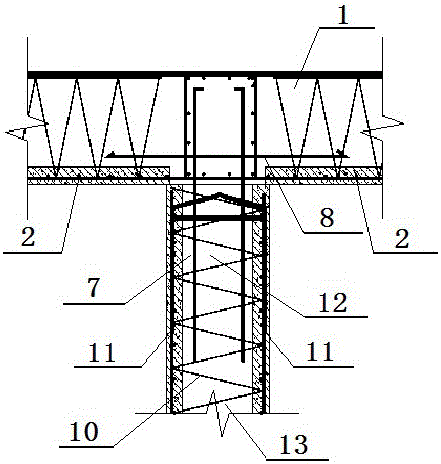

[0044]Referring to the accompanying drawings, for the composite assembled underground pipe gallery system of the present invention, its bottom plate is a cast-in-place bottom plate on the cushion layer of the underground pipe gallery, its side walls or side walls and intermediate walls are prefabricated sandwich laminated walls, and its top plate is Prefabricated laminated panels, the bottom plate, side walls or side walls, the middle wall, and the roof are connected by cast-in-place to form an integral underground pipe gallery. The connecting steel bars inside, the roof includes the prefabricated roof layer and the cast-in-place layer of the roof, the prefabricated sandwich laminated wall includes the prefabricated layers of the prefabricated sandwich laminated walls on both sides and the middle cast-in-place layer, the prefabricated sandwich laminated wall The prefabricated layer is pre-embedded with steel mesh, and the steel mesh in the prefabricated layer on both sides is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com