Preparation method of nitrogen-phosphorus co-doped carbon nanosheet and application of preparation method

A carbon nanosheet, co-doping technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as unfavorable large-scale application, high price, poor stability, etc., and achieve good The effect of methanol resistance, high current density and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

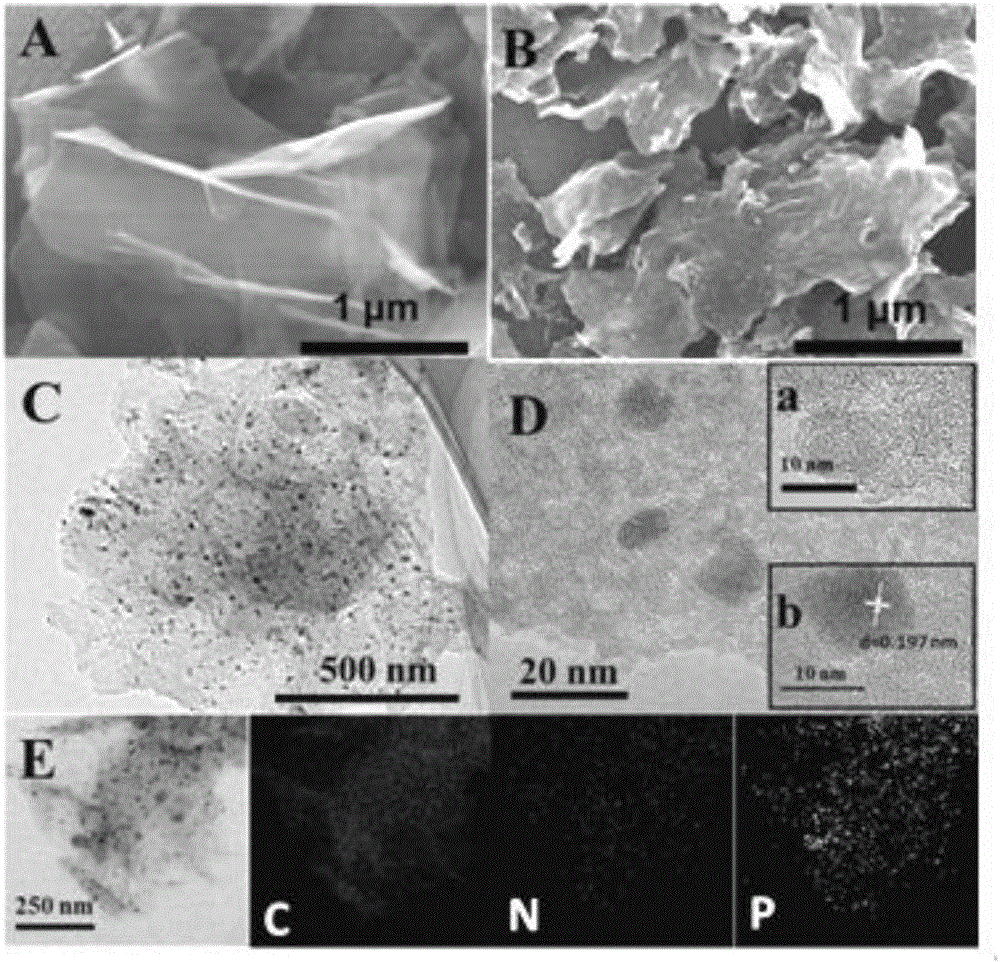

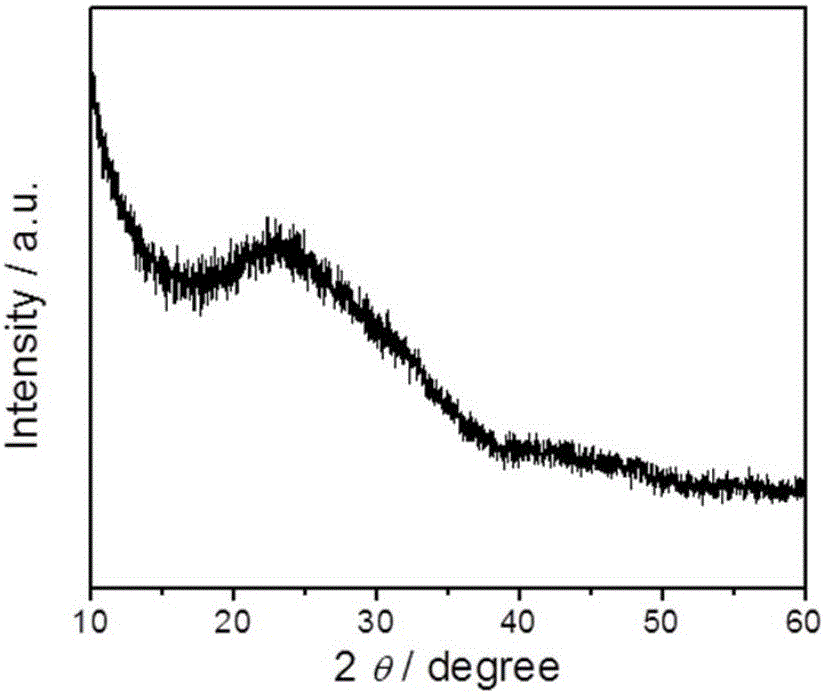

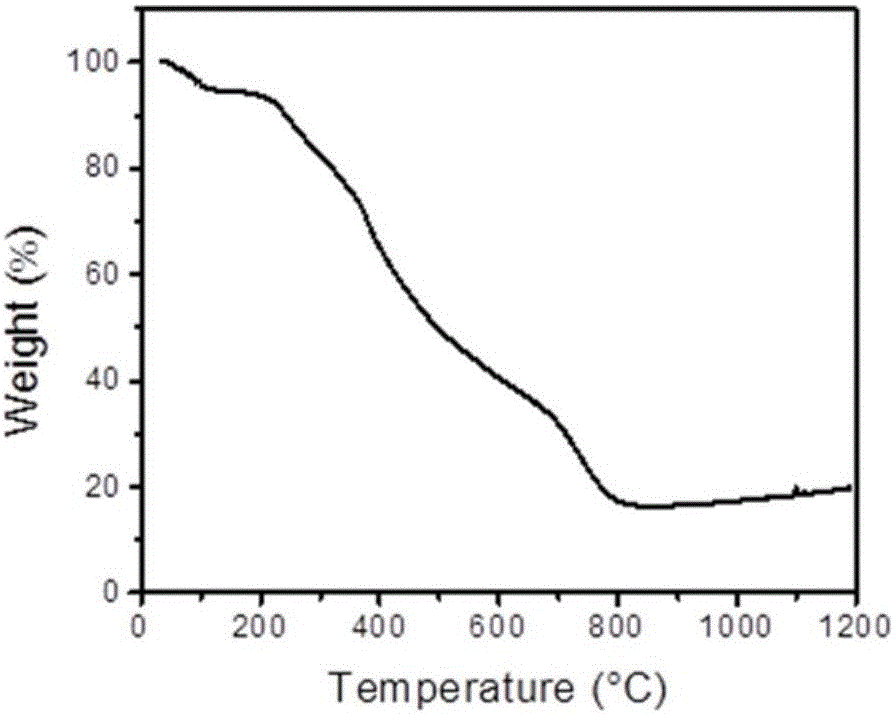

[0030] A preparation method of nitrogen and phosphorus co-doped carbon nanosheets, comprising the following steps:

[0031] 1) Preparation of self-assembled melamine precursor: Weigh 6mmol melamine and add it to 10ml deionized water, stir evenly, add 910uL phytic acid dropwise, stir fully and stand still to obtain a white hydrogel, freeze-dry the product to obtain a white fluffy powder.

[0032] 2) Preparation of nitrogen-phosphorus co-doped carbon nanosheet material (N-P / CNS): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, and heat it at 2 °C min under an argon atmosphere -1 The heating rate was raised to 700-1100°C and roasted for 2 hours to prepare nitrogen-phosphorus co-doped carbon nanosheets named N-P / CNS-700~N-P / CNS-1100, respectively.

Embodiment 2

[0034] A preparation method of nitrogen and phosphorus co-doped carbon nanosheets, comprising the following steps:

[0035] 1) Preparation of self-assembled melamine precursor: weigh melamine and add it to deionized water, stir evenly, add phytic acid dropwise, stir fully and stand still to obtain a white hydrogel, and freeze-dry the product to obtain a white fluffy powder. Wherein, the molar ratio of the melamine, phytic acid and water is 6:1:500.

[0036] 2) Preparation of nitrogen-phosphorus co-doped carbon nanosheet material (N-P / CNS): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, -1 The heating rate was increased to 1000°C for 1.5h to prepare nitrogen and phosphorus co-doped carbon nanosheets.

Embodiment 3

[0038] A preparation method of nitrogen and phosphorus co-doped carbon nanosheets, comprising the following steps:

[0039] 1) Preparation of self-assembled melamine precursor: weigh melamine and add it to deionized water, stir evenly, add phytic acid dropwise, stir fully and stand still to obtain a white hydrogel, and freeze-dry the product to obtain a white fluffy powder. Wherein, the molar ratio of the melamine, phytic acid and water is 6:3:600.

[0040] 2) Preparation of nitrogen-phosphorus co-doped carbon nanosheet material (N-P / CNS): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, -1 The heating rate was increased to 700°C for 2.5h to prepare nitrogen and phosphorus co-doped carbon nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com