Porous-heterostructure composite photocatalyst and preparation method thereof

A photocatalyst and heterostructure technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve good photocatalytic degradation of pollutants, simple process, high application prospects and practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

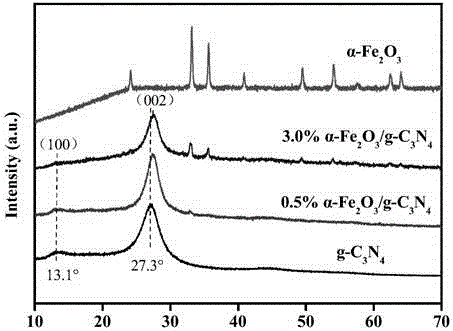

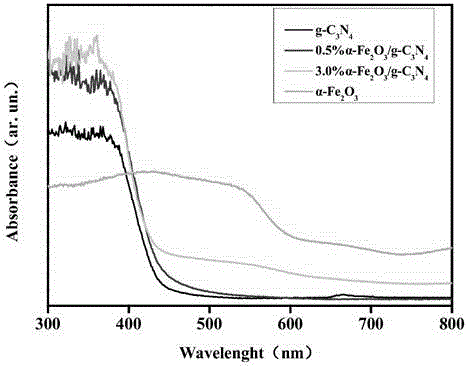

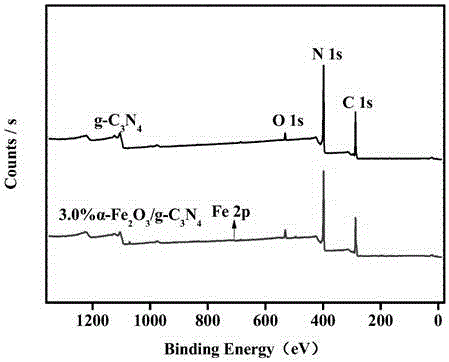

[0042] A porous heterostructure photocatalyst as α-Fe 2 o 3 / g -C 3 N 4 , the preparation method is as follows: take ferric nitrate and urea with a mass fraction of ferric nitrate of 0.5%, and place them in a container filled with distilled water; move the container to a water bath, and stir magnetically at a temperature of 20°C for 10 minutes, Obtain a solution; move the stirred solution in a water bath to an oven, and dry at 60°C for 4 hours to obtain a mixture of ferric nitrate and urea; move the dried mixture to a muffle furnace for calcination, wherein the heating rate during the heating process is 5°C / min, the constant temperature is 520°C, and the constant temperature time is 2h; after calcination, it is naturally cooled and ground to obtain a photocatalyst with a porous heterogeneous structure.

preparation Embodiment 2

[0044] A porous heterostructure photocatalyst as α-Fe 2 o 3 / g -C 3 N 4 , the preparation method is: taking ferric nitrate and urea with a mass fraction of ferric nitrate of 3.0%, placing them in a container filled with distilled water; moving the container to a water bath, stirring magnetically for 120 min at a temperature of 40°C, Obtain a solution; move the stirred solution in a water bath to an oven, and dry it at 100°C for 6 hours to obtain a mixture of ferric nitrate and urea; move the dried mixture to a muffle furnace for calcination, wherein the heating rate during the heating process is 20°C / min, the constant temperature is 580°C, and the constant temperature time is 4h; after calcination, it is naturally cooled and ground to obtain a photocatalyst with a porous heterogeneous structure.

preparation Embodiment 3

[0046] A porous heterostructure photocatalyst as α-Fe 2 o 3 / g -C 3 N 4 , the preparation method is as follows: take ferric nitrate and urea with a mass fraction of ferric nitrate of 1.5%, and place them in a container filled with distilled water; move the container to a water bath, and stir magnetically for 60 minutes at a temperature of 30° C., Obtain a solution; move the stirred solution in a water bath to an oven, and dry at 80°C for 6 hours to obtain a mixture of ferric nitrate and urea; move the dried mixture to a muffle furnace for calcination, wherein the heating rate during the heating process is 17°C / min, the constant temperature is 550°C, and the constant temperature time is 3h; after calcination, it is naturally cooled and ground to obtain a photocatalyst with a porous heterogeneous structure.

[0047] Comparative experiment 1

[0048] Preparation of α-Fe with Porous Heterostructure by Regulating the Ratio of Ferric Nitrate and Urea 2 o 3 / g -C 3 N 4 .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com