N-rich mesoporous carbon material and template-free preparation method thereof as well as method for manufacturing working electrode and application of working electrode

A technology of nitrogen-rich mesoporous and working electrodes, which is applied in the preparation/purification of carbon, etc., can solve the problem that the structure and composition of nitrogen-rich mesoporous carbon materials lack effective control of the arrangement and orientation of mesoporous surface atoms, and achieve low cost, The effect of large pore volume and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Preparation of nitrogen-rich mesoporous carbon

[0031] The structural formula of the building block used in the implementation case:

[0032]

Embodiment 1

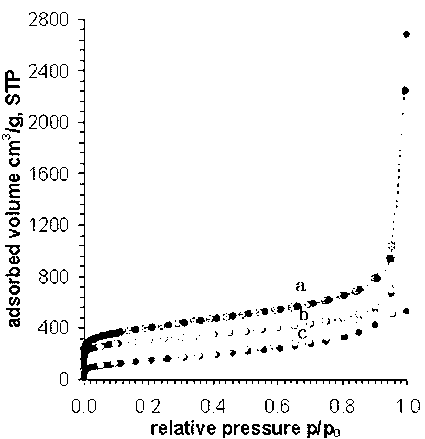

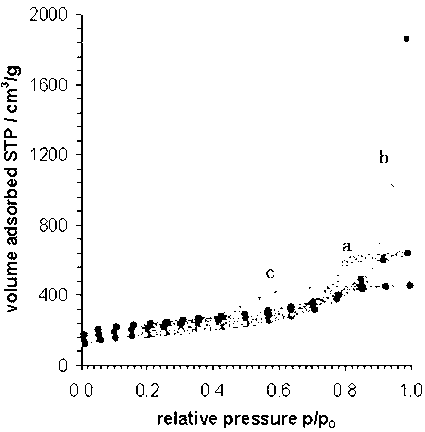

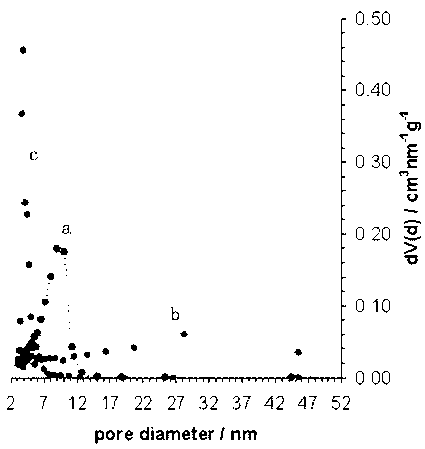

[0034] 307mg of melamine and 500mg of terephthalaldehyde (molar ratio 1:1.5) were placed in a three-necked flask, and 16mL of dimethyl sulfoxide solution was added to fully dissolve them. Heat to reflux at 180 °C for 72 hours under an inert atmosphere. After cooling to room temperature, the precipitate was filtered and separated by Buchner funnel and THF was extracted by Soxhlet to obtain a three-dimensional mesoporous polyimide white powder prepared by Schiff base chemical adjustment, with a yield of 61% and a pore volume of 1.01cm 3 g -1 , pore size 3.3nm, specific surface area 1377m 2 g -1 , where the nitrogen adsorption-desorption isotherm belongs to Type IV (such as figure 1 Shown in a), elemental analysis proves that the molar ratio of carbon to nitrogen in nitrogen-rich mesoporous carbon is 1:1.

[0035] Low-temperature calcination under argon or nitrogen to obtain a polyimide precursor with a high degree of polymerization, wherein the low-temperature calcination te...

Embodiment 2

[0037] 231 mg of melamine and 500 mg of p-naphthalene dicarbaldehyde ((molar ratio 1:1.5)) were placed in a three-necked flask, and 11 mL of dimethyl sulfoxide solution was added to fully dissolve them. Heat to reflux at 180 °C for 72 hours under an inert atmosphere. After cooling to room temperature, the precipitate was filtered and separated by Buchner funnel and THF was extracted by Soxhlet to obtain a light yellow powder of three-dimensional mesoporous polyimide prepared by Schiff base chemical adjustment, with a yield of 66% and a pore volume of 0.73 cm 3 g -1 , pore size 3.8nm, specific surface area 1032m 2 g -1 , where the nitrogen adsorption-desorption isotherm belongs to Type IV (such as figure 1 Shown in b), elemental analysis proves that the molar ratio of carbon to nitrogen in nitrogen-rich mesoporous carbon is 1:1.

[0038] Low-temperature calcination under argon or nitrogen to obtain a polyimide precursor with a high degree of polymerization, wherein the low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com