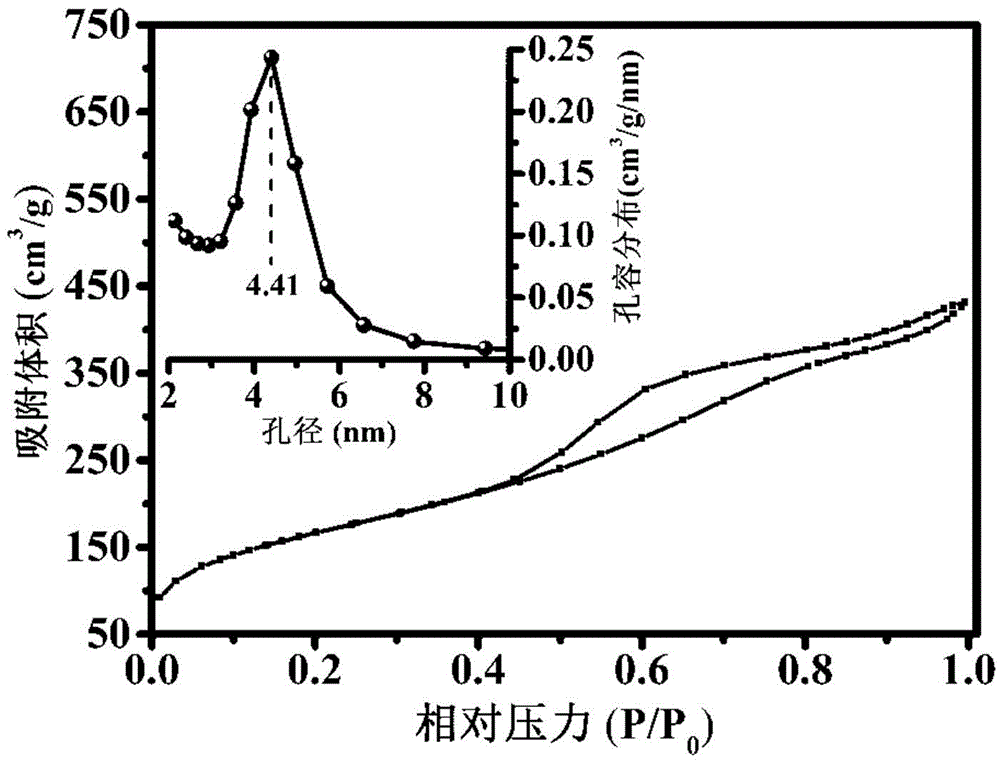

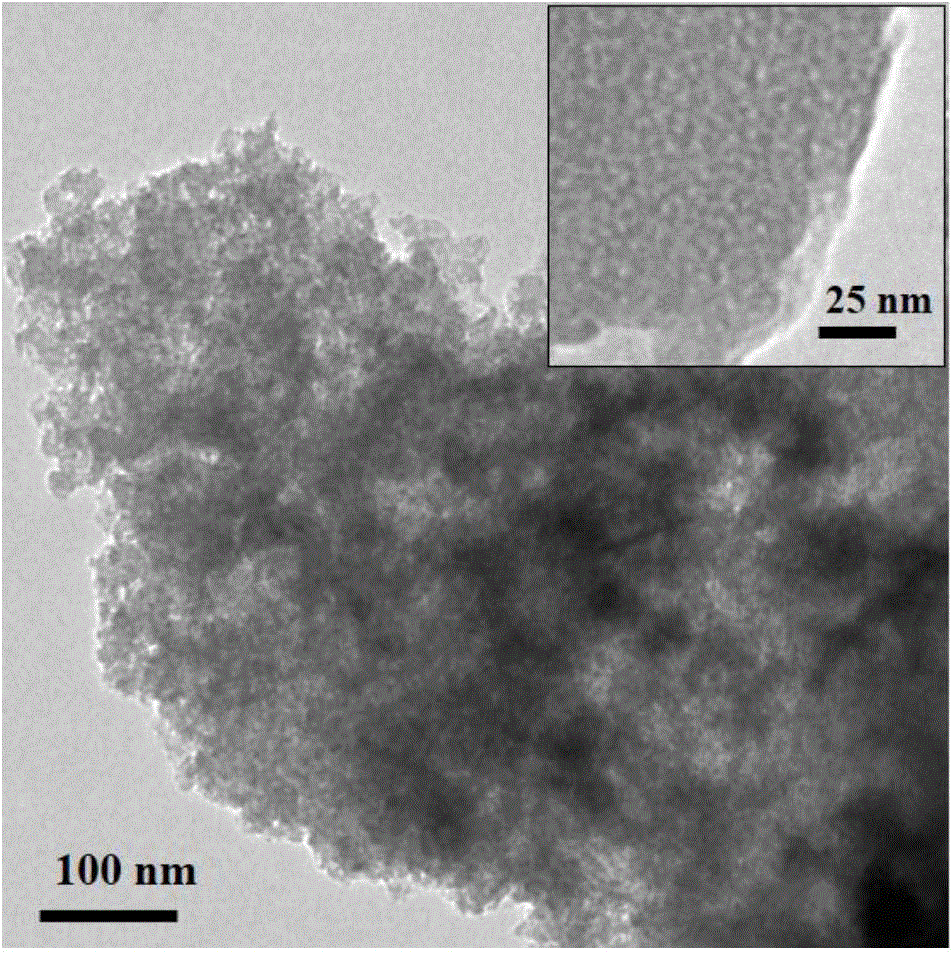

Preparation method of kaolin-based mesoporous silica material

A kaolin-based mesoporous technology, applied in the field of mesoporous materials, can solve the problem of low specific surface area and achieve the effects of simple production process, wide application prospects and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a kaolin-based mesoporous silicon oxide material, comprising the steps of:

[0030] (1) Calcination activation: place the kaolin in the calcination equipment and calcine it at 850°C for 2 hours, then take it out after cooling the equipment to obtain amorphous metakaolin;

[0031] (2) Hydrothermal alkali activation: Mix metakaolin obtained in step (1) with 4mol / L sodium hydroxide solution at a ratio of 1kg:20L, stir and react at 80°C for 0.5h, then filter and use Wash the obtained solid product with ionic water to neutrality, and then dry it at 110°C to remove water to obtain metakaolin after alkali activation (hydrothermal alkali activation);

[0032] (3) Acid etching: mix the alkali-activated metakaolin obtained in step (2) with 5mol / L HCl solution at a ratio of 1kg:20L, stir and react for 6h at 100°C, then filter and use The obtained solid product was washed with deionized water to neutrality, and then dried at 110° C. to remove water to obta...

Embodiment 2

[0035] A preparation method for a kaolin-based mesoporous silicon oxide material, comprising the steps of:

[0036] (1) Calcination activation: place kaolin in a calcination equipment and calcine at 600°C for 12 hours, then sample directly at high temperature to obtain amorphous metakaolin;

[0037] (2) Hydrothermal alkali activation: Mix the metakaolin obtained in step (1) with 1mol / L sodium hydroxide solution at a ratio of 1kg:50L, stir and react at 70°C for 12h, then centrifuge and deionize Wash the obtained solid product with water to neutrality, and then dry it at 110°C to remove water to obtain alkali-activated metakaolin;

[0038] (3) Acid etching: the alkali-activated metakaolin obtained in step (2) and 1mol / L of H 2 SO 4 The solution was mixed at a ratio of 1kg:50L, stirred and reacted at 40°C for 1h, then filtered and washed with deionized water until the solid product was neutral, and then dried at 110°C to remove water to obtain kaolin prepared by the template-free...

Embodiment 3

[0041] A preparation method for a kaolin-based mesoporous silicon oxide material, comprising the steps of:

[0042] (1) Calcination activation: place kaolin in a calcination equipment and calcine at 950°C for 0.5h, then take samples directly at high temperature to obtain amorphous metakaolin;

[0043] (2) Hydrothermal alkali activation: Mix the metakaolin obtained in step (1) with 9mol / L sodium hydroxide solution in a ratio of 1kg:4L and place it in an alkali-resistant container, stir and react at 80°C for 0.5 h, then filter and wash the obtained solid product with deionized water to neutrality, then dry at 110°C to remove moisture, and obtain metakaolin after alkali activation;

[0044] (3) Acid etching: the alkali-activated metakaolin obtained in step (2) was mixed with 2mol / L HNO 3 Mix with a mixed solution of 1mol / L HCl at a ratio of 1kg:4L, stir and react at 60°C for 10h, then filter and wash the obtained solid product with deionized water until neutral, and then dry at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com