Method for synthesizing lithium nickel cobalt manganese oxide used as anode material for lithium ion battery by template method

A technology of lithium-nickel-cobalt-manganese-manganate and lithium-ion batteries, which is applied in the field of lithium-ion battery anode material nickel-cobalt-manganese-oxide synthesis by the template method, can solve problems such as unfavorable lithium ion diffusion, and achieve the benefits of intercalation and extraction, and reduce precipitation and deposition The effect of speed and small particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

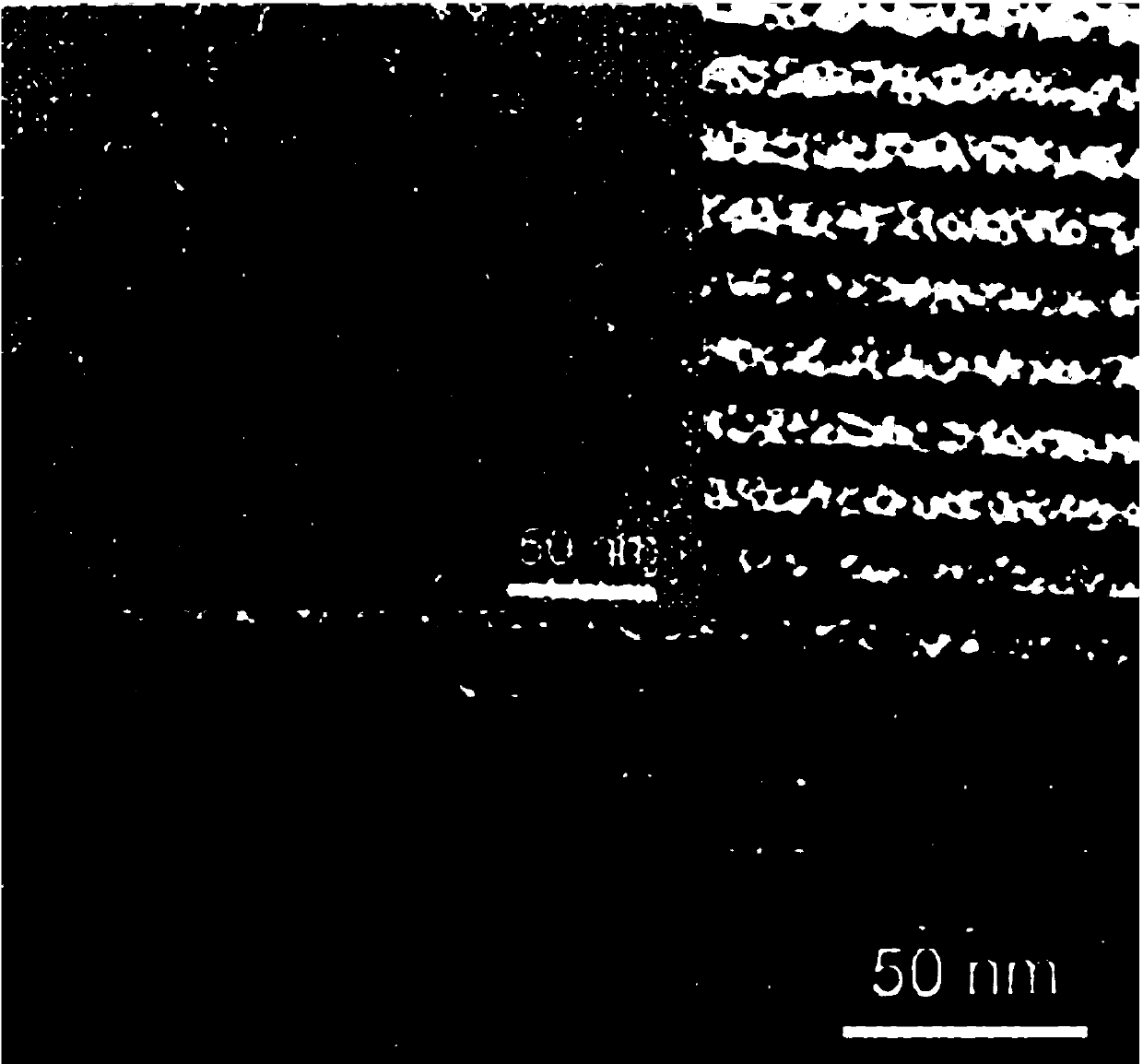

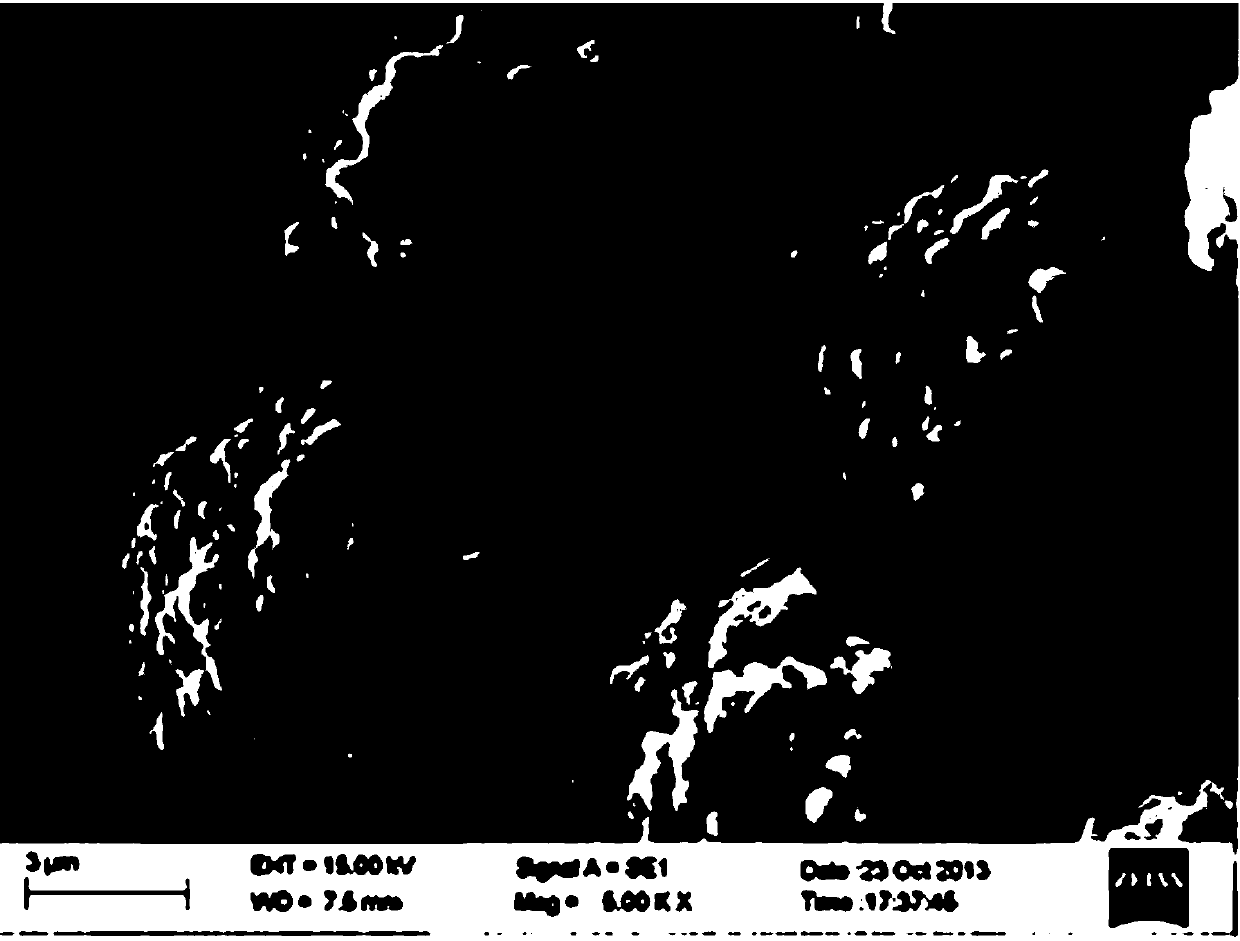

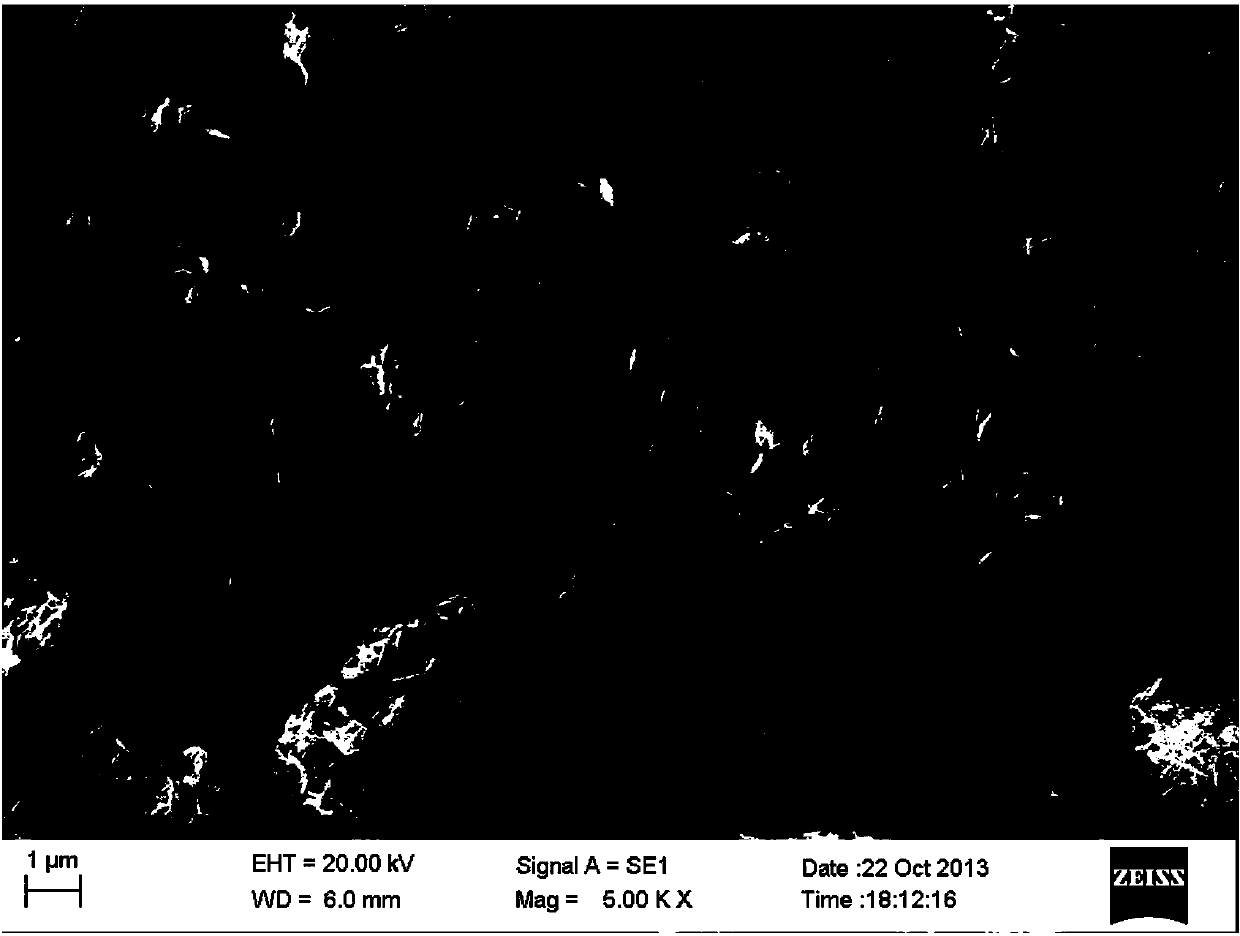

[0037] The present invention as figure 1 , 2 , Shown in 3, 4, a kind of template synthesis method of lithium ion battery cathode material nickel cobalt manganese oxide lithium, it is characterized in that: concrete steps are as follows:

[0038] (1) Dissolve lithium salt, nickel salt, cobalt salt, and manganese salt in water-organic solvent in molar ratio to form a metal solution. The molar ratio of lithium to nickel, cobalt, and manganese is 1.1:1 / 3:1 / 3: 1 / 3, the total molar concentration of lithium, nickel, cobalt, and manganese ions is 3-4mol / L, and in the water-organic solvent mixture, the mass ratio of water to the mixture is 10-40wt%;

[0039] (2) Prepare a mixed aqueous solution of ammonia water, ammonium carbonate and polyethylene glycol, the concentration of ammonia water is 0.5-2mol / L, and the concentration of ammonium carbonate is 3-5 mol / L;

[0040] (3) Add the solution in (1) to silica molecular sieve, add the mixed aqueous solution in step (2) dropwise into the...

Embodiment 1

[0049] (1) Configure a mixed solution of lithium hydroxide, nickel sulfate, cobalt sulfate, and manganese sulfate. The molar ratio of lithium hydroxide, nickel sulfate, cobalt sulfate, and manganese sulfate is 1.1:1 / 3:1 / 3:1 / 3. The total concentration of nickel sulfate, cobalt sulfate and manganese sulfate in the mixed solution is 2mol / L, the solvent is a water-ethanol mixture, and the mass percentage of water is 20%;

[0050] (2) Prepare a mixed aqueous solution of ammonia, ammonium carbonate and polyethylene glycol, the concentration of ammonia is 1mol / L, the concentration of ammonium carbonate is 4mol / L, and polyethylene glycol accounts for 3% of the total mass of the mixed lye;

[0051] (3) Add a certain quality of SBA-15 molecular sieve to the solution in (1), and drop the mixed aqueous solution in step (2) into the solution under mechanical stirring conditions, so that the metal solution, SBA-15 and mixed lye are fully Mix and mechanically stir for 10 hours to obtain the...

Embodiment 2

[0057] (1) Configure a mixed solution of lithium hydroxide, nickel sulfate, cobalt sulfate, and manganese sulfate. The molar ratio of lithium hydroxide, nickel sulfate, cobalt sulfate, and manganese sulfate is 1.1:1 / 3:1 / 3:1 / 3. The total concentration of nickel sulfate, cobalt sulfate and manganese sulfate in the mixed solution is 2mol / L, the solvent is a water-ethanol mixture, and the mass percentage of water is 40%;

[0058] (2) Prepare a mixed aqueous solution of ammonia water, ammonium carbonate and polyethylene glycol, the concentration of ammonia water is 1mol / L, the concentration of ammonium carbonate is 4mol / L, and polyethylene glycol accounts for 5% of the total mass of the mixed lye;

[0059] (3) Add a certain quality of SBA-15 molecular sieve to the solution in (1), and add the mixed aqueous solution in step (2) dropwise to the solution under mechanical stirring conditions, so that the metal solution, SBA-15 and mixed lye are fully Mix and mechanically stir for 10 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com