Preparation of toluene shape-selective disproportionation without adhesive

A binder-free and catalyst-free technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of complicated operation process, difficult industrial application, long process time, etc., and achieve simple process, environmental protection, The effect of fewer modification times and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

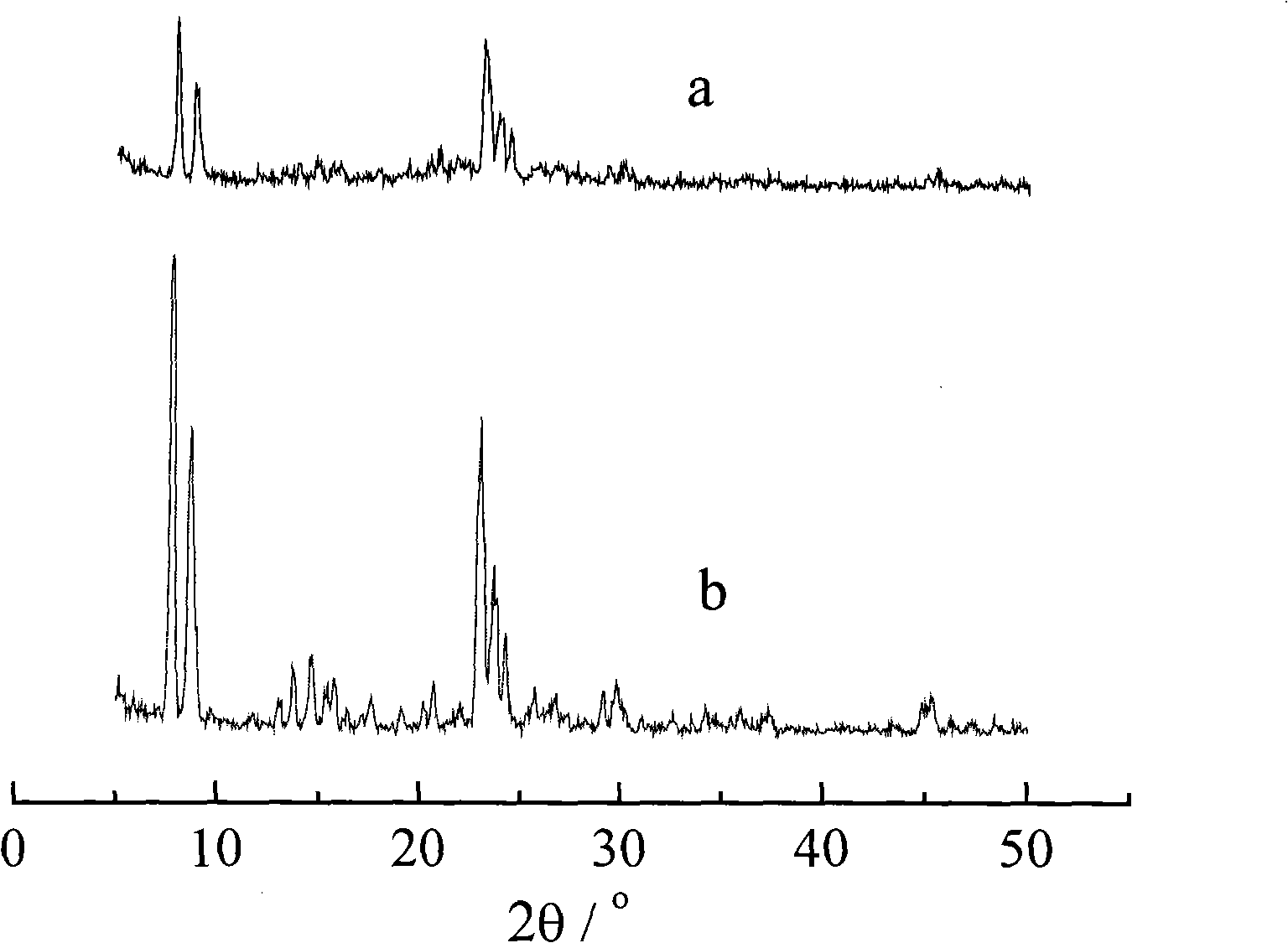

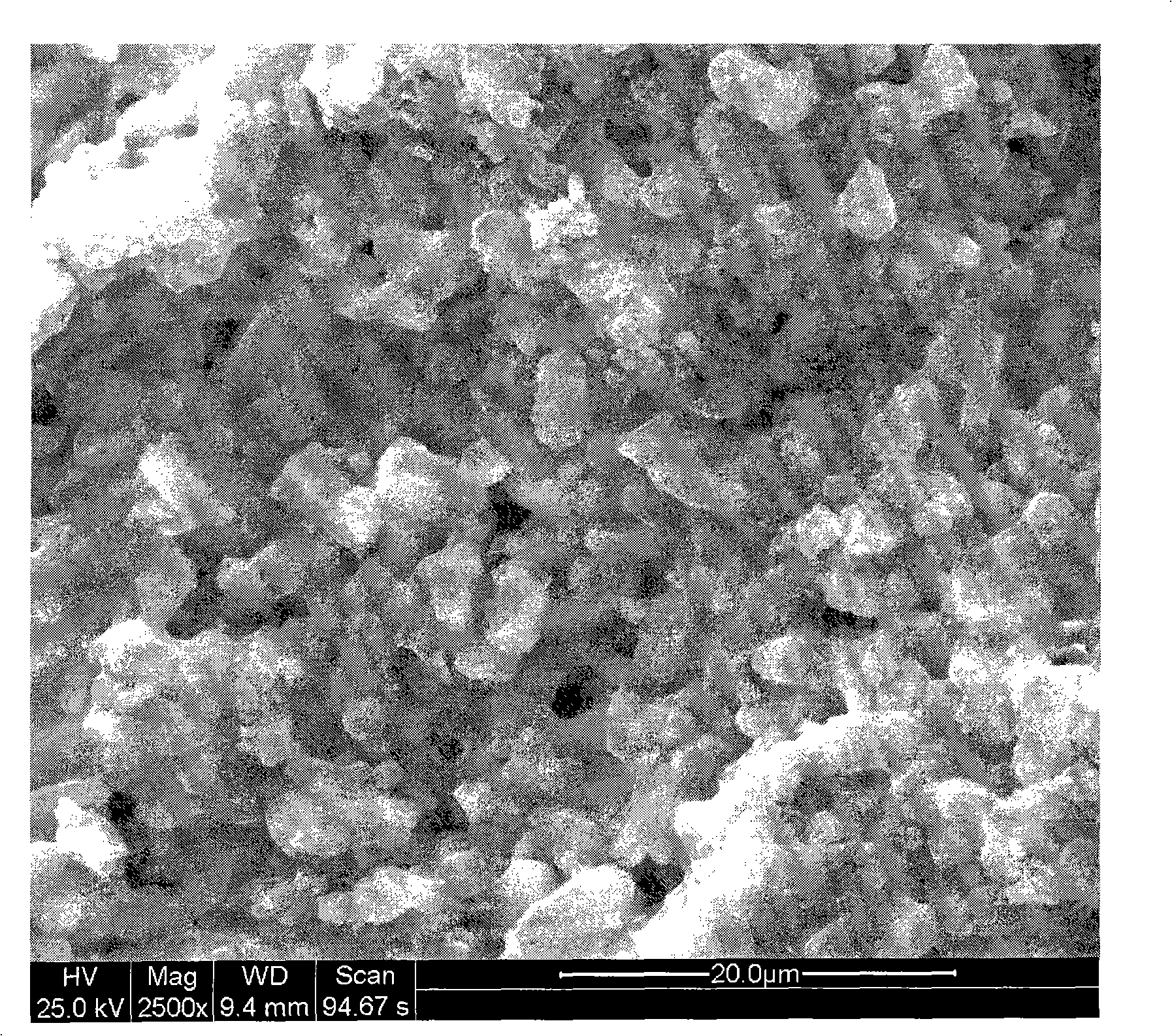

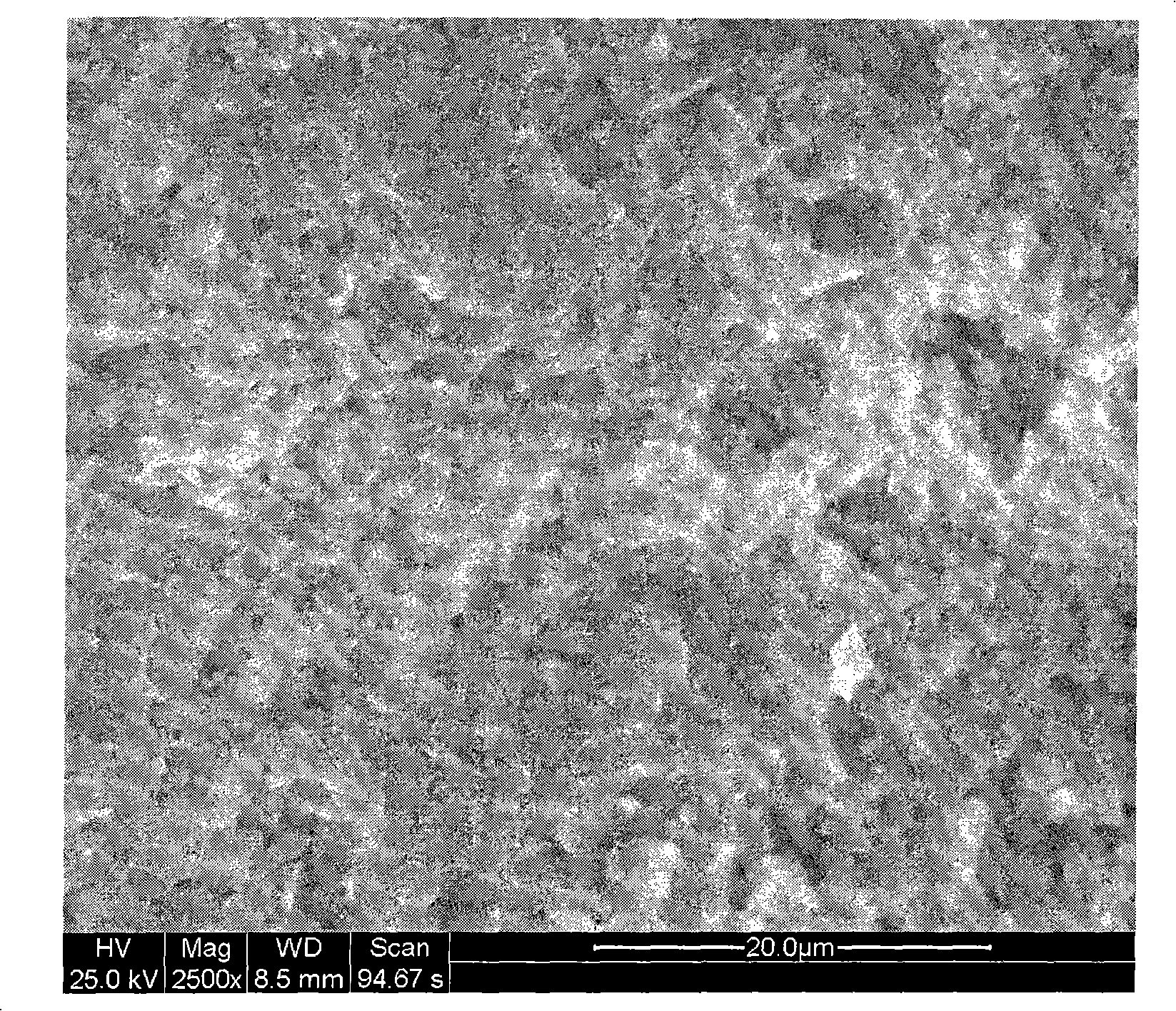

[0023] Take 80 parts by weight of ZSM-5 zeolite with a silicon-aluminum ratio of 38 and 20 parts of silica sol (calculated as silicon dioxide) and mix, then add 1 part of kale powder and water to knead and extrude into strips, dry it, Calcined at a high temperature of 550° C. for 3 hours to obtain a shaped catalyst with a length of 10 mm and a diameter of 2 mm. Put 10 g of shaped catalyst into 10 g of 60% ethanol-NaOH solution with a pH of 12, and crystallize at 190° C. for 48 h. Take out the solid sample after crystallization, wash to neutrality with deionized water, XRD result shows, the crystallinity of sample increases, and silica has been converted into the zeolite of MFI structure in above-mentioned hydrothermal system (see attached figure 1 ), with figure 2 and 3 The SEM results show that the binder after hydrothermal crystallization has been transformed into a zeolite with a small-grained MFI structure, and is well covered on the surface of the procatalyst.

Embodiment 2

[0025] Take 70 parts by weight of ZSM-5 zeolite with a silicon-aluminum ratio of 38 and 30 parts of white carbon black, add 2 parts of citric acid and an appropriate amount of water, knead and extrude it, dry it, and bake it at a high temperature of 600 ° C for 2 hours. A shaped catalyst with a length of 10 mm and a diameter of 2 mm was obtained. Put 10 g of the shaped catalyst into 20 g of 40% ethanol-KOH solution with a pH of 13, and crystallize at 160° C. for 120 h. The solid sample after crystallization was taken out, washed with deionization until neutral, and XRD characterization showed that the crystallinity of the sample increased, and the silica had been transformed into a zeolite with MFI structure.

Embodiment 3

[0027] Take 60 parts by weight of ZSM-5 zeolite with a silicon-aluminum ratio of 38, 39 parts of silica sol (calculated as silica), and 1 part of aluminum hydroxide sol (calculated as alumina) and mix them, and add 1 part of fiber It was kneaded and extruded by plain and appropriate amount of water, dried and calcined at 400°C for 8 hours to obtain a molded catalyst with a length of 10 mm and a diameter of 2 mm. Put 10 g of shaped catalyst into 20 g of 80% ethanol-NaOH solution with a pH of 13, and crystallize at 200° C. for 48 h. The solid sample after crystallization was taken out and washed with deionization to neutrality. The XRD characterization showed that the crystallinity of the sample increased, and the binder had been transformed into a zeolite with MFI structure.

[0028] Example 3

[0029] Get 70 parts by weight of ZSM-5 zeolite with a silicon-aluminum ratio of 38, 29.5 parts of silica sol (calculated as silicon dioxide), and 0.5 part of aluminum sulfate (calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com