Catalyst for elimination of formaldehyde at room temperature and preparation method thereof

A technology for eliminating formaldehyde and catalysts, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that non-precious metal catalysts cannot completely catalyze the oxidation of formaldehyde, formaldehyde catalytic oxidation has not been further studied, poor moisture resistance and other problems, to achieve excellent formaldehyde adsorption capacity and moisture resistance, excellent stability and moisture resistance, simple use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

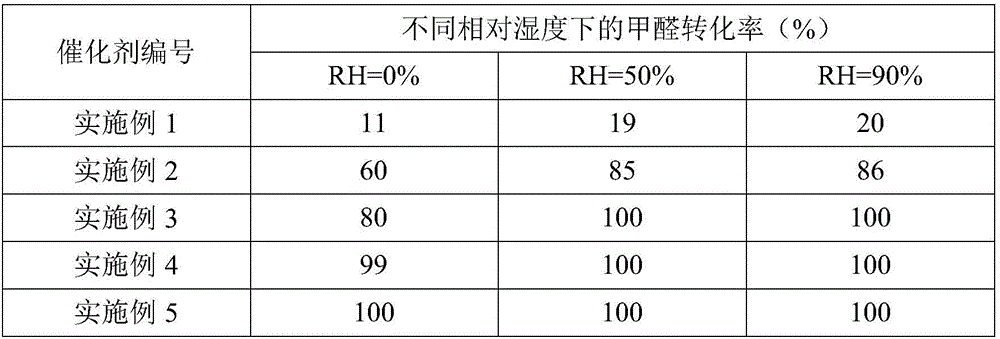

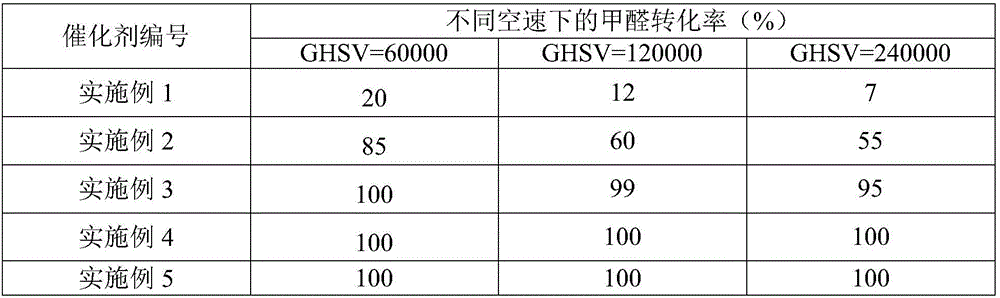

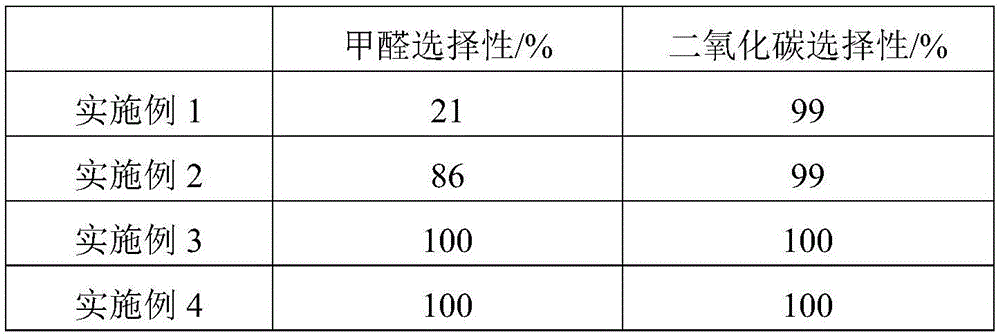

Examples

preparation example Construction

[0037] The preparation method of the exemplary Beta molecular sieve carrier-loaded catalyst for room temperature formaldehyde purification comprises the steps:

[0038] (1) According to the published synthesis method, the Beta molecular sieve was synthesized by the template-free seed crystal method.

[0039] (2) The molecular sieve is treated, and a certain amount of Beta molecular sieve is ion-exchanged with a certain amount of ammonium nitrate, potassium nitrate or sodium nitrate, filtered, washed, and dried. Repeat 2 to 3 times.

[0040] (3) Template-free seed crystal method Beta is used as a carrier, and the carrier is pretreated by calcination, and the calcination temperature is 400-600°C.

[0041] (4) Impregnation method: impregnate a certain amount of Beta synthesized by the template-free seed crystal method after a certain amount of roasting in a certain amount of aqueous solution of noble metal active components, ultrasonic for 5 to 30 minutes, stirred for 1 to 4 hou...

Embodiment 1

[0047] The Beta molecular sieve is synthesized by the organic template-free seed crystal method, and the Beta molecular sieve is ion-exchanged with ammonium nitrate, then filtered, washed, and dried; repeating 2-3 times, and the obtained sample is roasted at 400°C. Immerse the roasted Beta molecular sieve in an aqueous solution containing chloroplatinic acid, ultrasonicate for 30 minutes, stir for 4 hours, and age overnight; stir the mixed solution with a glass rod at 120°C, evaporate the water in the mixed solution to make the active group Evenly load on the Beta molecular sieve, continue to dry at 150 ° C for 5 hours; then move to the muffle furnace under air conditions, and bake at 400 ° C for 5 hours to obtain a catalyst with platinum as the active component. The mass of the active component is The content is 0.1%. .

[0048] Before use, the catalyst is first placed in a hydrogen atmosphere, heat-treated at 200° C. for 4 hours, and then sieved into particles with a size o...

Embodiment 2

[0050] The rest are the same as in Example 1, except that the percentage of platinum removal is 0.2%, and the heat treatment is controlled at 400° C. for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com