Rubber elastomer-based rapid forming material

A rubber elastic body, fast technology, applied in the direction of additive processing, etc., can solve the problems of low production speed, difficulty in meeting the requirements of rubber products, high production cost, etc., achieve low cost, simple and easy preparation method, and good product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

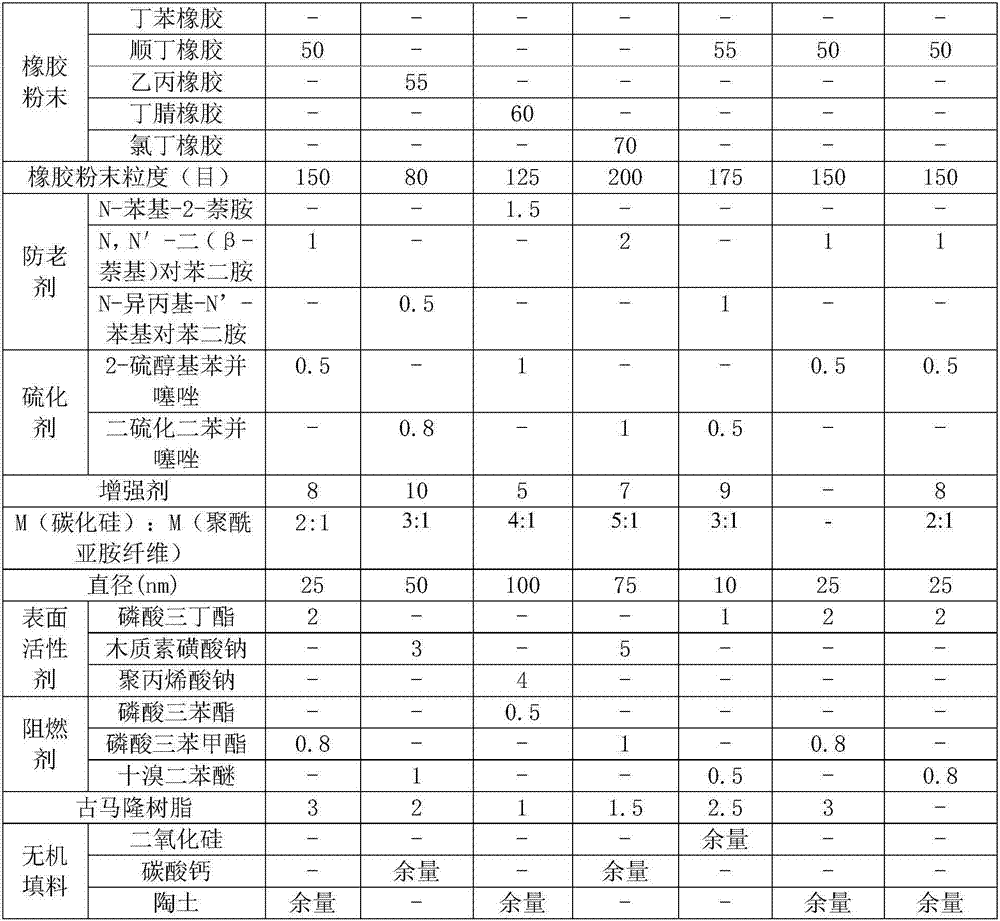

Embodiment 1

[0022] A kind of rapid prototyping raw material based on rubber elastic body, by weight percentage, comprises following components: 100 mesh styrene-butadiene rubber powder 55%, N-phenyl-2-naphthylamine 1%, 2-thiol benzothiazole 0.5%, nano-silicon carbide whiskers and polyimide fibers are mixed at a weight ratio of 3:1, 5% of reinforcing agent with a diameter of 20nm, 3% of tributyl phosphate, 0.5% of triphenyl phosphate, Guma Long resin 1%, silicon dioxide balance.

[0023] The preparation method of the described rapid prototyping raw material based on rubber elastic body, comprises the steps:

[0024] (1) After mixing the rubber powder, anti-aging agent, reinforcing agent, surfactant, flame retardant, plasticizer and inorganic filler according to the predetermined ratio, put them into the open mixer for mixing, and control the temperature at 40°C. Mixing for 10-20min;

[0025] (2) After mixing evenly, discharge the material to the tablet press and add vulcanizing agent, ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com