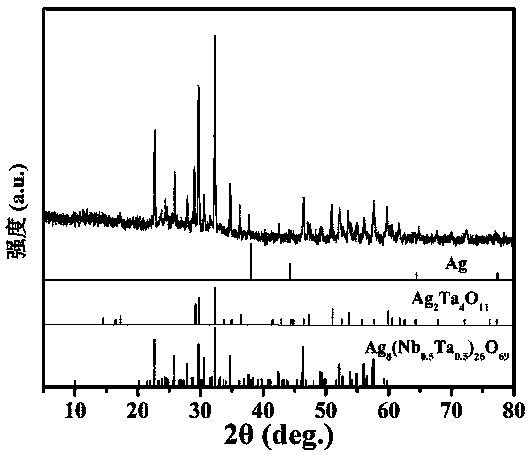

Preparation method of visible light catalyzing material silver tantalite for completely and rapidly degrading formaldehyde and benzene of indoor environment

A technology for rapid degradation and catalytic materials, applied in chemical instruments and methods, separation methods, catalysts for physical/chemical processes, etc., can solve the problems of high recombination rate of photogenerated electrons and holes, low catalytic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

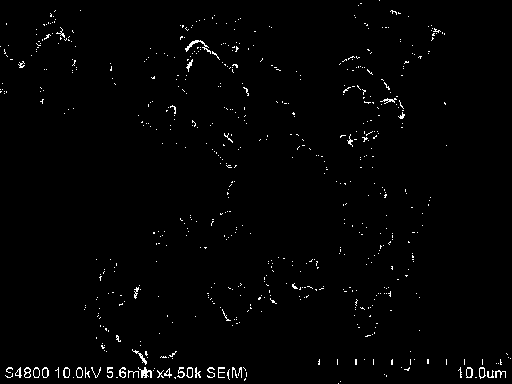

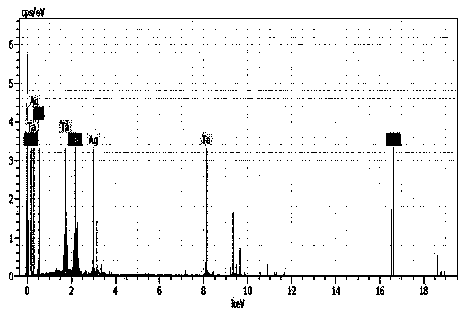

Method used

Image

Examples

Embodiment

[0018] Embodiment: 15 milligrams of the three-phase catalyst of synthesis are uniformly dispersed on the glass surface by ethanol, and after drying, put it in a reactor with a volume of 2 liters, equipped with an air circulation device, and the light source is a 300W xenon lamp with a visible light filter (wavelength greater than 420 nm). Formaldehyde and benzene in the reactor are brought into the reaction device by air bubbling, the concentration is controlled by adjusting the airflow, and the changes of substances in the reaction gas are detected by gas infrared detector and gas chromatography. Degradation see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com