Photoresist stripper composition

A technology of photoresist and stripping solution, which is applied in the processing of photosensitive materials, etc., can solve the problems that the photoresist film cannot be removed cleanly and the corrosion of the substrate is aggravated, and achieves excellent stripping effect, low implementation temperature, The effect of cost minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

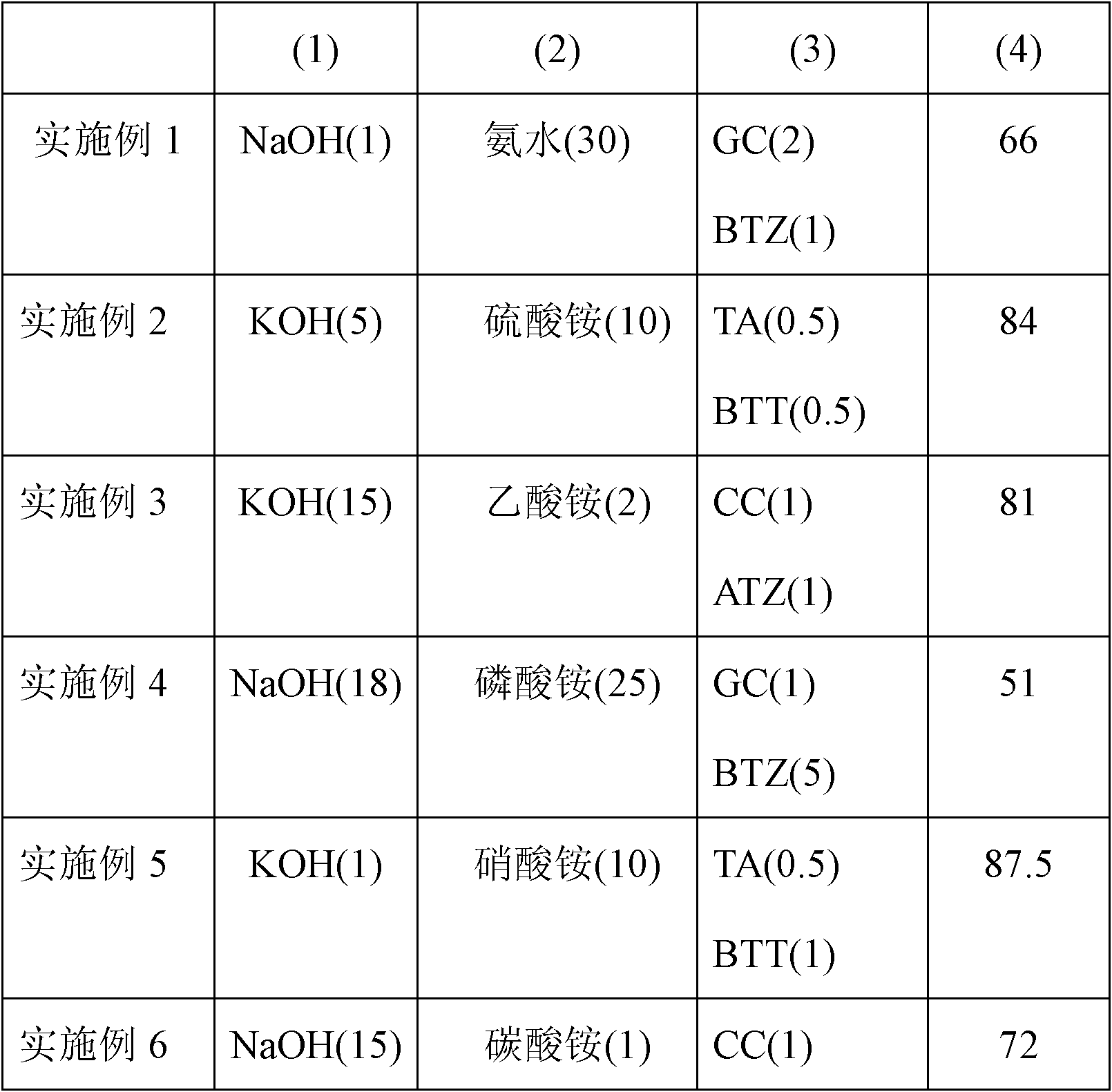

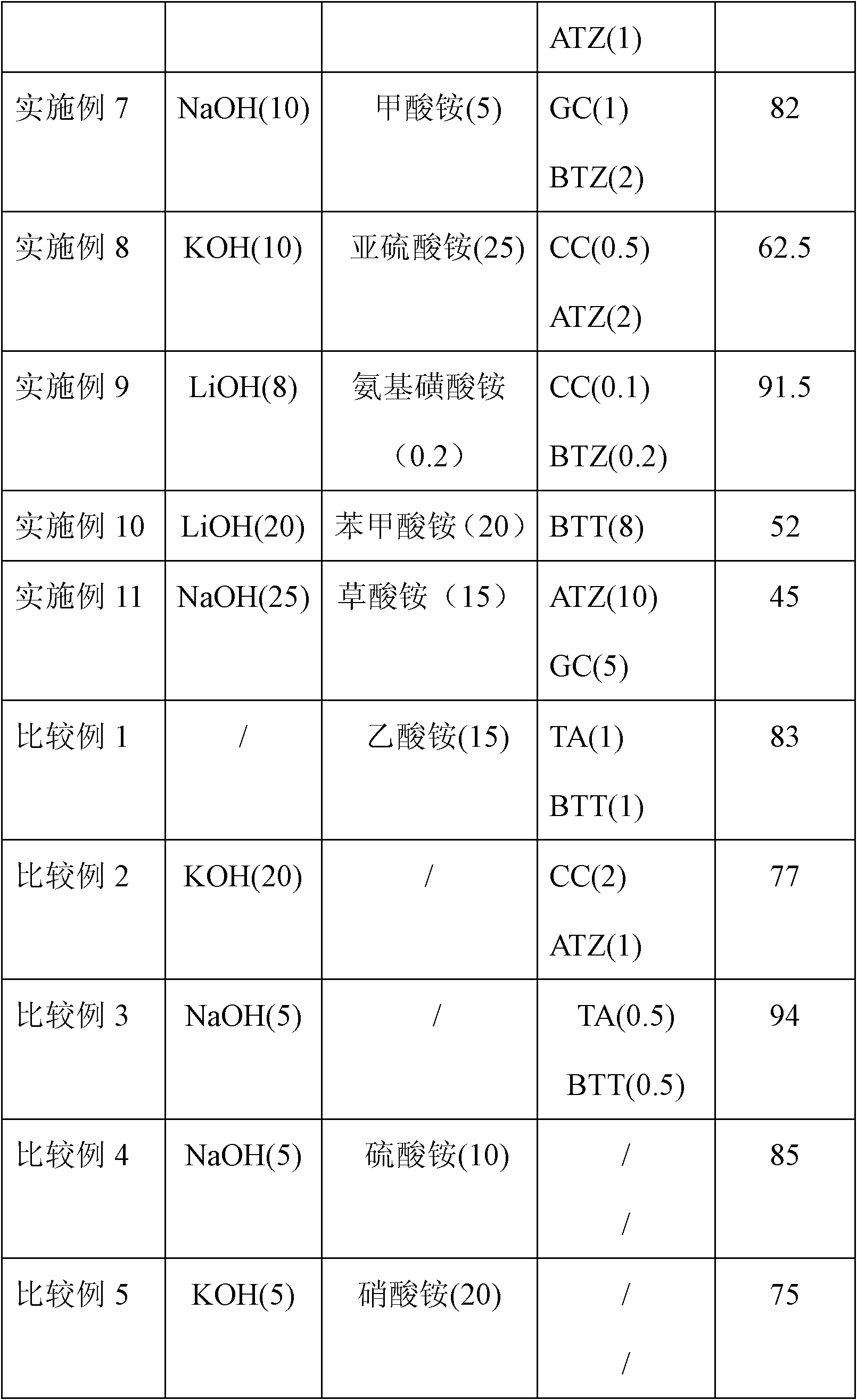

Examples

Embodiment Construction

[0031] The photoresist stripper composition of the present invention is a composition containing an inorganic base, at least one of ammonia water and ammonium salt, a corrosion inhibitor, and water.

[0032] The inorganic base described in the present invention includes one or two of sodium hydroxide, potassium hydroxide and lithium hydroxide. The content of the inorganic base is 1wt%-25wt%, preferably 5-20wt%, more preferably 8-15wt%. When the concentration is less than 1wt%, the effect of effectively stripping the photoresist film cannot be achieved; greater than 25wt% , it will aggravate the corrosion of the base material.

[0033] The ammonia water or / and the ammonium salt described in the present invention act synergistically to strip the photoresist film. The ammonium salt is selected from ammonium sulfate, ammonium bisulfate, ammonium sulfite, ammonium bisulfite, ammonium nitrate, ammonium carbonate, ammonium bicarbonate, ammonium chloride, ammonium bromide, ammonium f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com