Composite visible-light-responding photocatalyst material, and preparation method and application thereof

A photocatalyst and visible light technology, used in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of expensive preparation of basic materials, limited development and wide application, and short service life of photocatalysts. , to achieve the effects of improved photocatalytic degradation efficiency, improved photocatalytic degradation efficiency, and significant absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

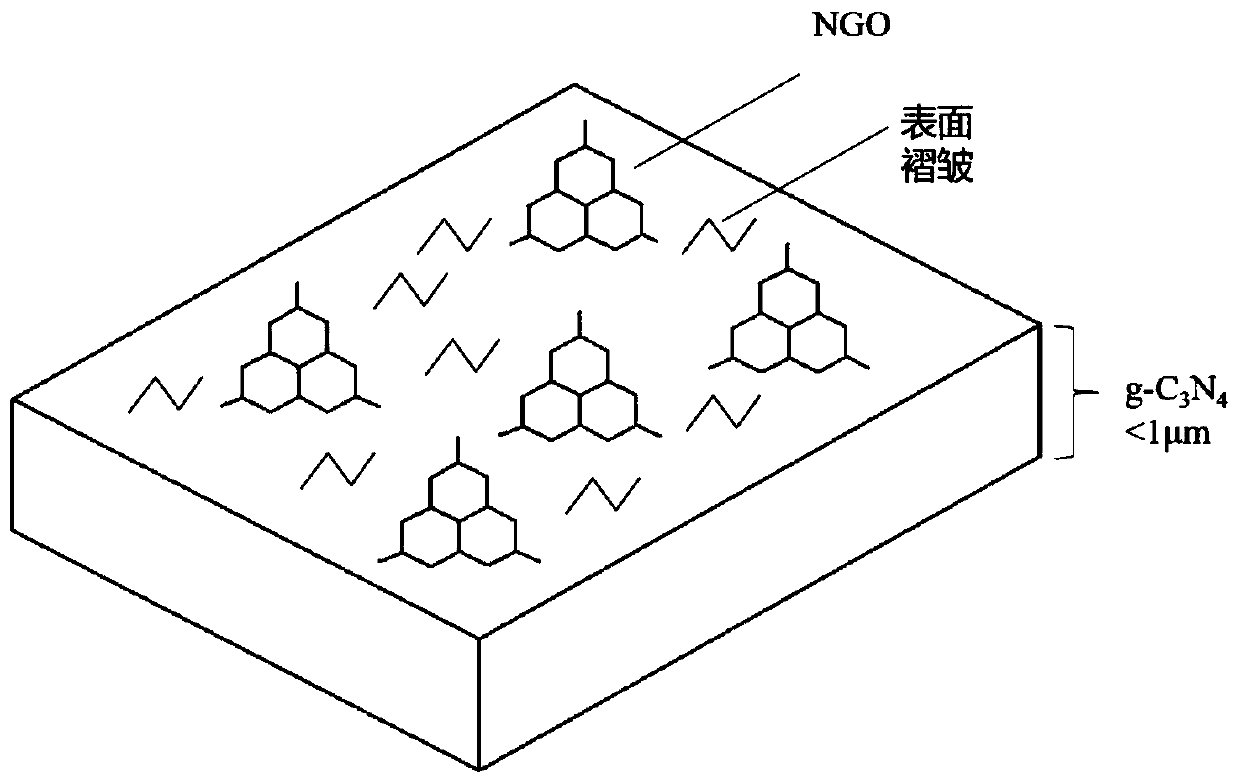

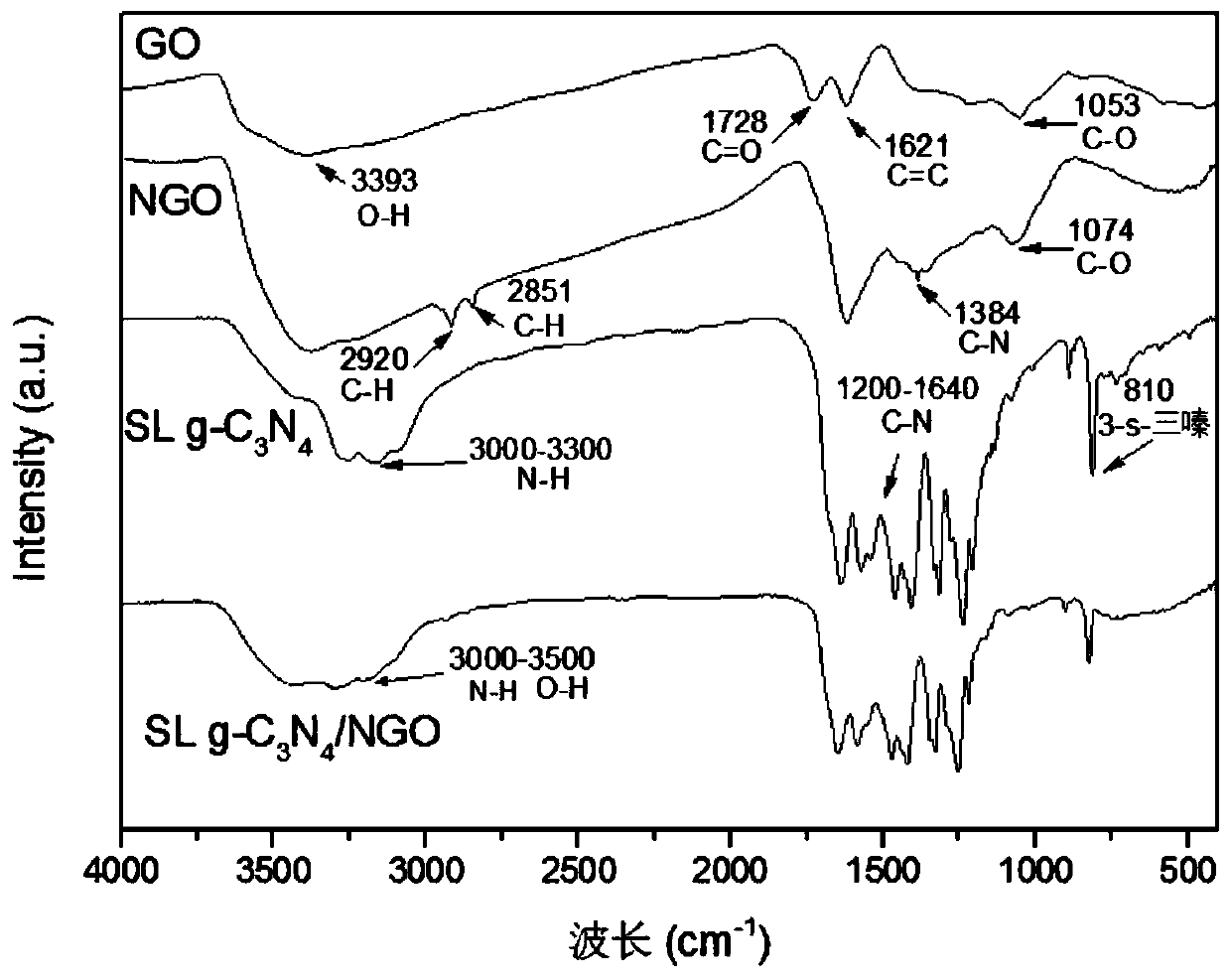

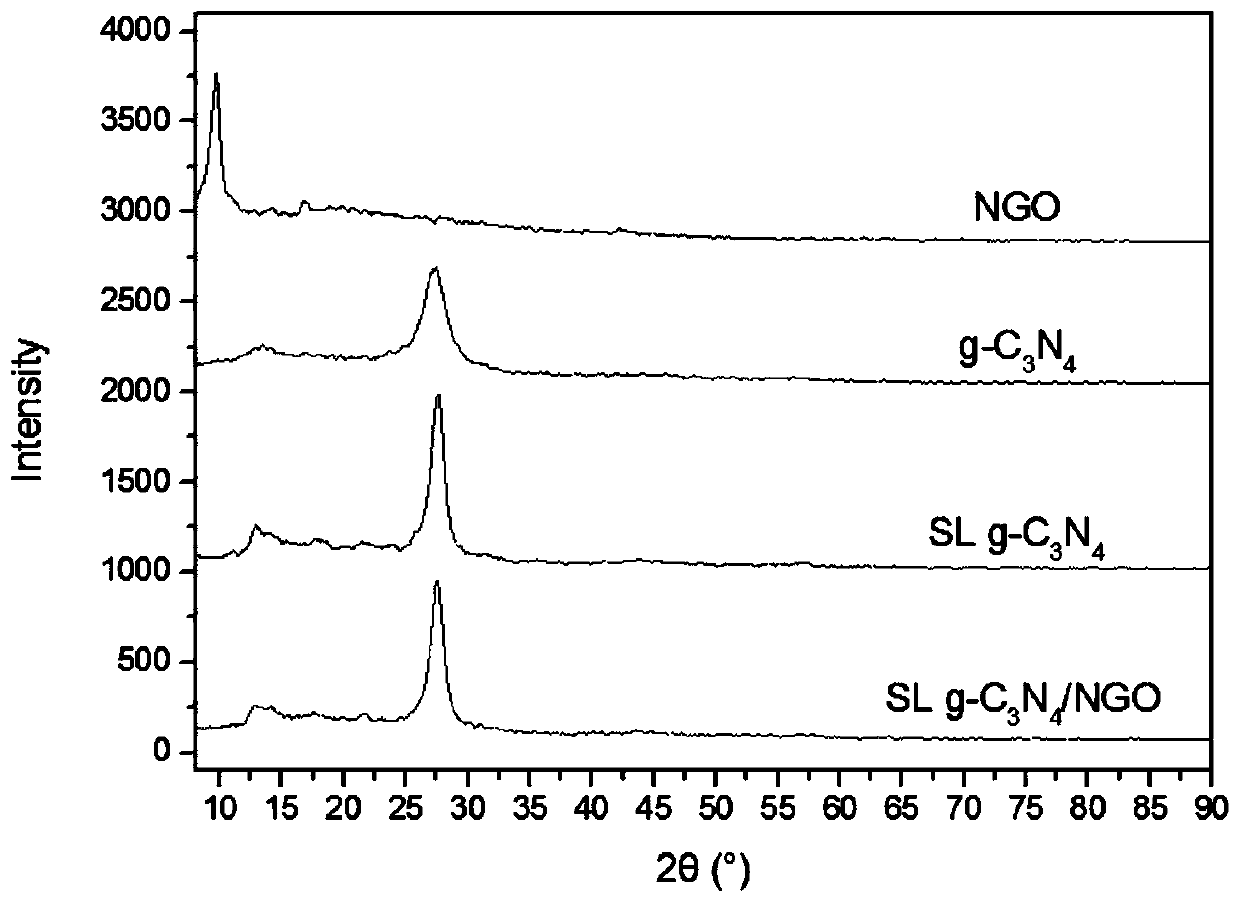

[0056] (1) Nanosheet structure SLg-C 3 N 4 Preparation of:

[0057] Preparation of nanosheet g-C by secondary calcination 3 N 4 (Abbreviation: SL g-C 3 N 4 ): Dissolve urea and melamine in a mass ratio of 6:1, then dry the mixed solution at 80°C, grind the obtained powder and put it into an alumina crucible, then place the crucible in a muffle furnace, The rate of ℃ / min-15℃ / min is raised to 250℃-350℃ and kept for 60-100min to obtain block g-C 3 N 4 ;Take block g-C 3 N 4 Put it into a crucible after grinding, place the crucible in a muffle furnace for secondary calcination, raise the temperature at a rate of 10°C / min-15°C / min to 350°C-520°C and keep it for 60-100min to obtain g-C 3 N 4 Powder; finally put it in isopropanol and ultrasonically peel it for 1h-3h, centrifuge and dry to get nanosheet g-C 3 N 4 , which is SL g-C 3 N 4 ;

[0058] (2) Preparation of aminated graphene oxide NGO:

[0059] Preparation of aminated graphene oxide NGO using ethylenediamine: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com