Preparation method and application of magnetically-separatable TNTs/g-C3N4 nano-composite material

A nanocomposite material, g-c3n4 technology, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc., can solve problems such as limitations, difficult solid-liquid separation, low photocatalytic activity, etc. and hole separation efficiency, solving recycling difficulties, and expanding the visible light response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

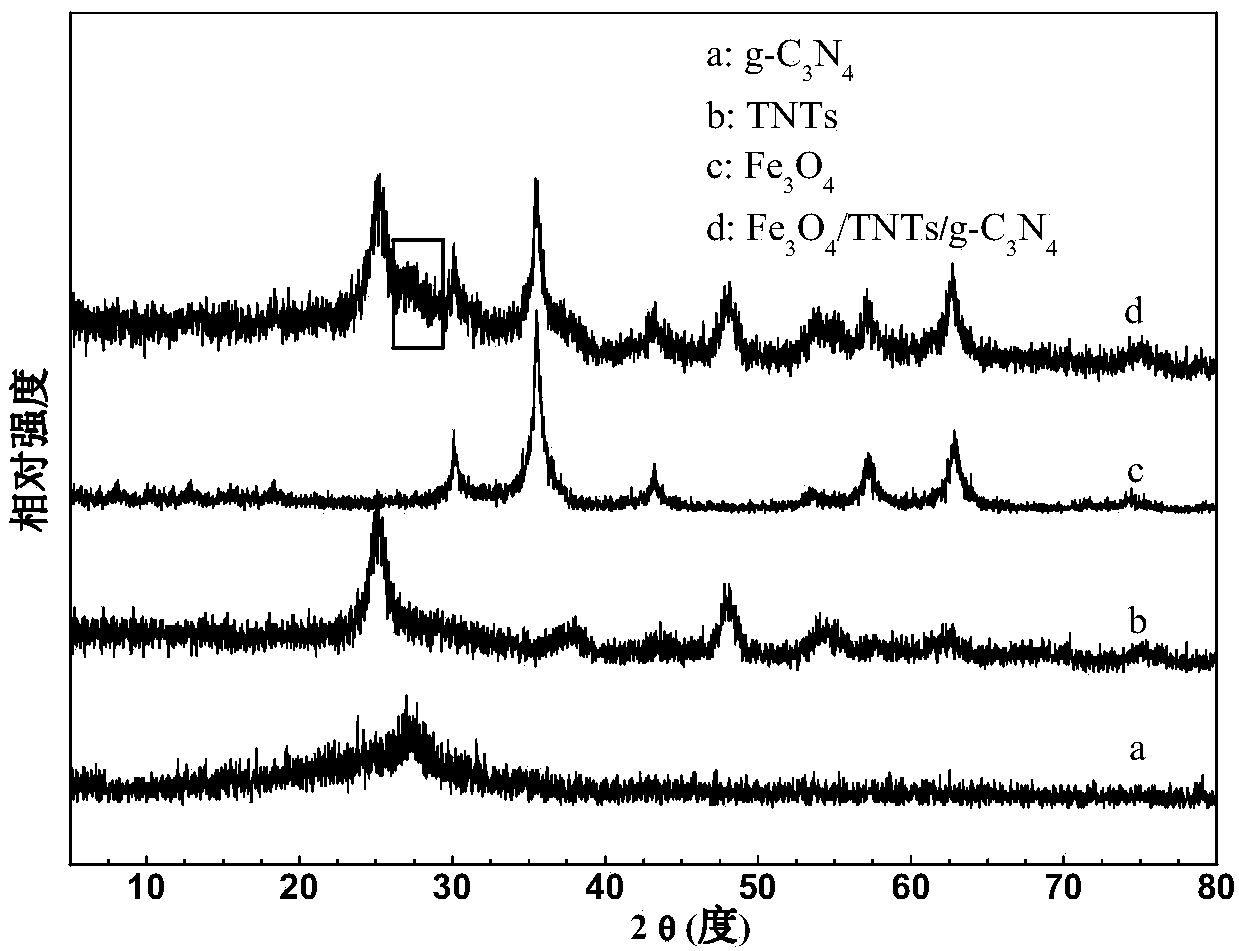

[0019] The invention discloses a magnetically separable TNTs / g-C 3 N 4 The preparation method of nanocomposite material, comprises the following steps, takes a certain amount of g-C 3 N 4 Disperse in 50ml deionized water and sonicate for 1 hour to obtain a uniform dispersion, and stir a certain amount of P 25 Slowly add g-C 3 N 4 In the dispersion, continue ultrasonication for 0.5h, stir for 0.5h to ensure complete mixing, and then add a certain amount of FeCl with a molar ratio of 2:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for another 15 minutes and stir for 15 minutes to ensure complete mixing. 1M NaOH solution was added dropwise to the above mixture to make the pH of the solution equal to 10, and then a certain amount of NaOH was added to transfer the mixture into a hydrothermal reaction kettle, and then the reaction kettle was heated at 120° C. for 24 hours. After cooling, wash with deionized water until neutral, then soak with 0.01M HCl solution ...

Embodiment 2

[0039] A magnetically separable TNTs / g-C 3 N 4 The preparation method of nanocomposite material, comprises the following steps, takes a certain amount of g-C 3 N 4 Disperse in 50ml deionized water and sonicate for 0.8 hours to obtain a uniform dispersion, and stir a certain amount of P 25 Slowly add g-C 3 N 4 In the dispersion, continue ultrasonication for 0.4h, stir for 0.4h to ensure complete mixing, and then add a certain amount of FeCl with a molar ratio of 2.5:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for 12 minutes, stir for 15 minutes to ensure complete mixing; add 0.8M NaOH solution dropwise to the above mixture to make the pH of the solution equal to 10, then add a certain amount of NaOH to transfer the mixture to a hydrothermal Then heat the reactor at 100°C for 24 hours; wash it with deionized water until it is neutral, and soak it with 0.01M HCl solution for 0.8 hours; finally wash it with deionized water several times, and then wash it with...

Embodiment 3

[0043] A magnetically separable TNTs / g-C 3 N 4 The preparation method of nanocomposite material, comprises the following steps, takes a certain amount of g-C 3 N 4 Dispersed in 50ml of deionized water and ultrasonically treated for 1.2 hours to obtain a uniform dispersion, a certain amount of P 25 Slowly add g-C 3 N 4 In the dispersion, continue ultrasonication for 0.6h, stir for 0.6h to ensure complete mixing, and then add a certain amount of FeCl with a molar ratio of 3.5:1 3 ·6H 2 O and FeSO 4 ·7H 2 O, then continue to sonicate for 16 minutes, stir for 15 minutes to ensure complete mixing; add 1.2M NaOH solution dropwise to the above mixture to make the pH of the solution equal to 10, then add a certain amount of NaOH to transfer the mixture to a hydrothermal Then heat the reactor at 140°C for 24 hours; wash it with deionized water until it is neutral, and soak it with 0.01M HCl solution for 1.2 hours; finally wash it with deionized water several times, and then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com