Preparation method of injection molding grade UHMWPE (Ultra-High Molecular Weight Polyethylene)

A technology of ultra-high molecular weight and polyethylene, which is applied in the field of polymer compound modification processing, can solve the problem of poor flow modification effect, etc., and achieve the reduction of van der Waals force, increase of fluidity and mechanical properties, and high flow performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

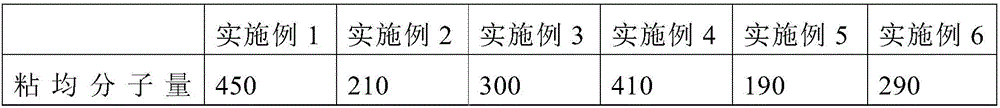

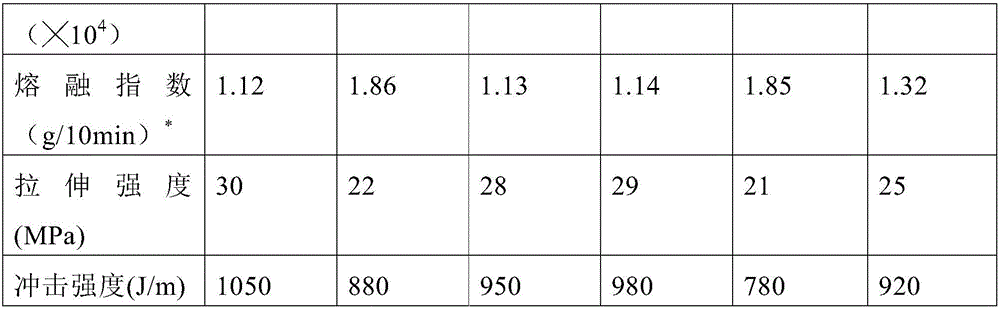

Examples

Embodiment 1

[0026] a. Heat the reactor to the reaction temperature of 70°C, vacuumize and dry, then replace with nitrogen, add 90 parts of 120# gasoline, 1 part of white oil and 0.001 part of alkylaluminum / TiCl 4 Catalyst, feed 100 parts of ethylene under the stirring condition of 400r / min, control the pressure to 0.5MPa, and react at the reaction temperature for 5 hours. After drying, obtain ultra-high molecular weight polyethylene resin containing solvent naphtha;

[0027] b. Dilute 0.01 part of vinyl siloxane with 0.04 part of ethanol, stir 5 parts of ultrafine molybdenum disulfide powder with a high-speed mixer, and spray the diluted vinyl siloxane on it until the spray is evenly wet, and then put The mixture is air-dried;

[0028] c. Mix 0.7 parts of antioxidant 1010, 5 parts of high-density polyethylene, 5 parts of low-density polyethylene, 5 parts of polyethylene wax, 100 parts of the resin obtained in step a and the mixture obtained in step b at 10°C for 10 minute;

[0029] d. ...

Embodiment 2

[0032] a. Heat the reactor to the reaction temperature of 90°C, vacuumize and dry, then replace with nitrogen, add 200 parts of hexane, 20 parts of kerosene and 0.005 parts of alkylaluminum / TiCl 4 Catalyst, feed 100 parts of ethylene under the stirring condition of 1200r / min, control the pressure at 0.8MPa, react at the reaction temperature for 1 hour, after the reaction is completed, quickly cool to 50°C, filter the hexane to obtain a slurry, and dry the slurry After obtaining the ultra-high molecular weight polyethylene resin containing solvent naphtha;

[0033] b. Dilute 0.05 parts of vinyl siloxane with 0.1 part of ethanol, stir 5 parts of graphite and 5 parts of ultrafine molybdenum disulfide powder with a high-speed mixer, and spray the diluted vinyl siloxane on it until the spray is uniform and wet until the mixture is air-dried;

[0034] c. 0.4 parts of antioxidant 168, 10 parts of high-density polyethylene, 100 parts of the resin obtained in step a and the mixture ob...

Embodiment 3

[0038] a. Heat the reactor to the reaction temperature of 80°C, vacuumize and dry, then replace with nitrogen, add 100 parts of heptane, 10 parts of paraffin oil and 0.002 parts of alkylaluminum / TiCl 4 Catalyst, feed 100 parts of ethylene under the stirring condition of 1000r / min, control the pressure to 0.6MPa, react at the reaction temperature for 4 hours, after the reaction is completed, quickly cool to 30°C, filter the heptane to obtain a slurry, and dry the slurry After obtaining the ultra-high molecular weight polyethylene resin containing solvent naphtha;

[0039] b. Dilute 0.02 parts of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate with 0.2 parts of ethanol, stir 3 parts of montmorillonite and 3 parts of talcum powder with a high-speed mixer, and put on top Spray diluted isopropyl dioleate (dioctyl phosphate acyloxy) titanate until the spray is evenly wet, then allow the mixture to air dry;

[0040] c. Mix 0.5 parts of antioxidant 1076, 5 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com