Preparation method for few-layer graphene

A technology of graphene and a few layers, which is applied in the field of graphene prepared by ultrasonic-assisted supercritical carbon dioxide technology combined with micro-spraying, which can solve the problem of low graphene production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

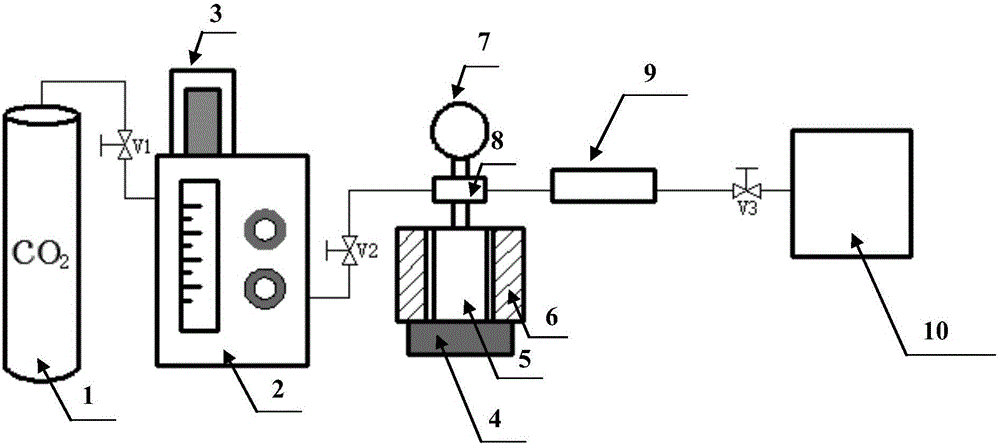

Method used

Image

Examples

Embodiment 1

[0025] (1) Weigh 1g of high-temperature pyrolytic graphite powder and place it in a 200ml autoclave 5;

[0026] (2) In the autoclave 5, the material is heated to 80°C, and the CO 2 Inject into the autoclave 5, when the pressure in the autoclave 5 reaches 16 MPa, the ultrasonic probe 4 starts to work under a power of 100 W, and at the same time, the stirring device 8 is turned on to start stirring.

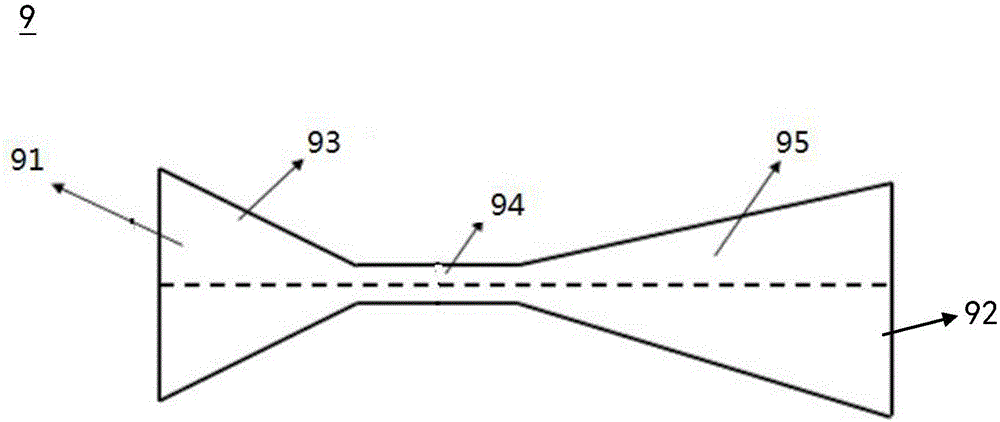

[0027] (3) After the ultrasonic and stirring time in the autoclave 5 reaches 120 minutes, open the valve between the autoclave 5 and the micro-jet stripping device 9. After the high-pressure material comes out of the autoclave 5, it is sprayed into the micro-jet stripping device 9 A rapid pressure relief process is performed in the atmospheric receiving tank 10 to obtain a graphene product.

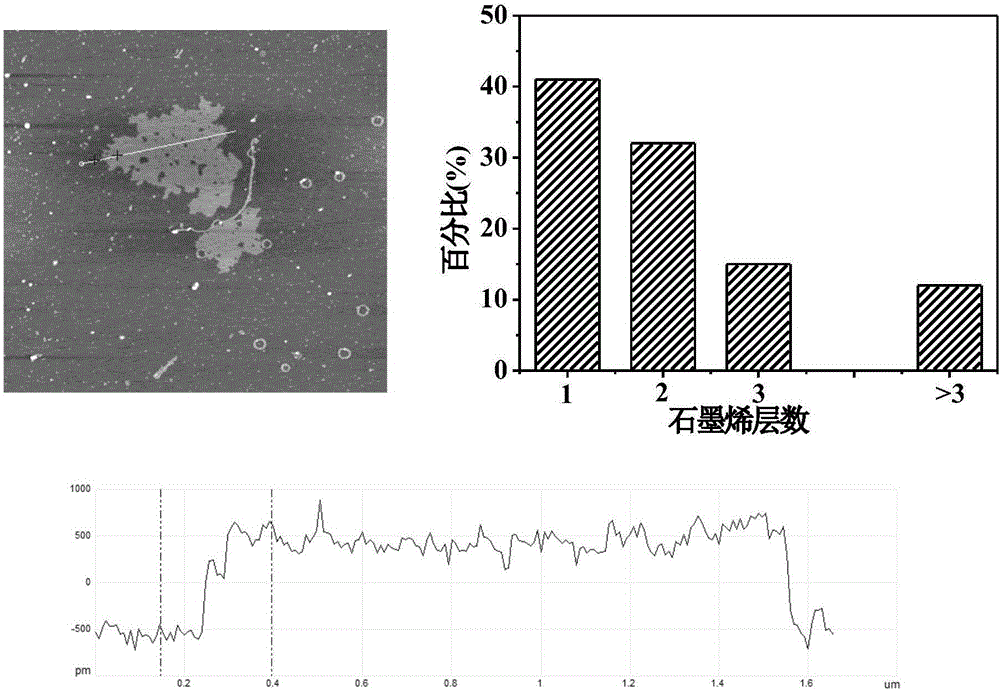

[0028] Through testing and characterization, the sample has less than 3 layers of graphene accounting for 88%, of which single-layer graphene accounts for 41%. See image 3 .

Embodiment 2

[0030] (1) Weigh 0.5g of natural graphite powder and place it in a 200ml autoclave 5;

[0031] (2) In the autoclave 5, the materials are heated to 60℃, and the CO 2 Inject into the autoclave 5, when the pressure in the autoclave 5 reaches 8Mpa, the ultrasonic probe 4 starts to work at a power of 300W, and at the same time, the stirring device 8 is turned on to start stirring.

[0032] (3) After the ultrasonic and stirring time in the autoclave 5 reaches 60 minutes, open the valve between the autoclave 5 and the micro-jet stripping device 9. After the high-pressure material comes out of the autoclave 5, it is sprayed into the normal temperature through the micro-jet stripping device 9 A rapid pressure relief process is performed in the pressure receiving tank 10 to obtain a graphene product.

[0033] Through testing and characterization, the sample has less than 3 layers of graphene accounting for 94%, of which single-layer graphene accounts for 45%. Figure 4 .

Embodiment 3

[0035] (1) Weigh 0.2g of expanded graphite powder and place it in a 200ml autoclave 5;

[0036] (2) In the autoclave 5, the materials are heated to 40℃, and the CO 2 Inject into the autoclave 5, when the pressure in the autoclave 5 reaches 13Mpa, the ultrasonic probe 4 starts to work under 1000W power, and at the same time the stirring device 8 is turned on to start stirring.

[0037] (3) After the ultrasonic and stirring time in the autoclave 5 reaches 30 minutes, open the valve between the autoclave 5 and the micro-jet stripping device 9. After the high-pressure material comes out of the autoclave 5, it is sprayed into the normal temperature through the micro-jet stripping device 9 The pressure in the pressure receiving tank 10 is quickly released to obtain a graphene product.

[0038] Through testing and characterization, the sample has less than 3 layers of graphene accounting for 91%, of which single-layer graphene accounts for 43%, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com