Ammoniated ultrathin graphite-phase carbonitride photocatalyst and preparation method thereof

A graphite phase carbon nitride, phase carbon nitride light technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve unfavorable carbon dioxide adsorption and reduction, reduced catalytic performance, difficult to obtain effect and other problems, to achieve the effect of low production cost, no equipment, and excellent photocatalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Precursor treatment: Dissolve melamine solid in anhydrous ethanol solution to form a clear solution, then add 0.5M nitric acid solution dropwise, a white precipitate is formed, then filter the white precipitate and vacuum dry it for later use;

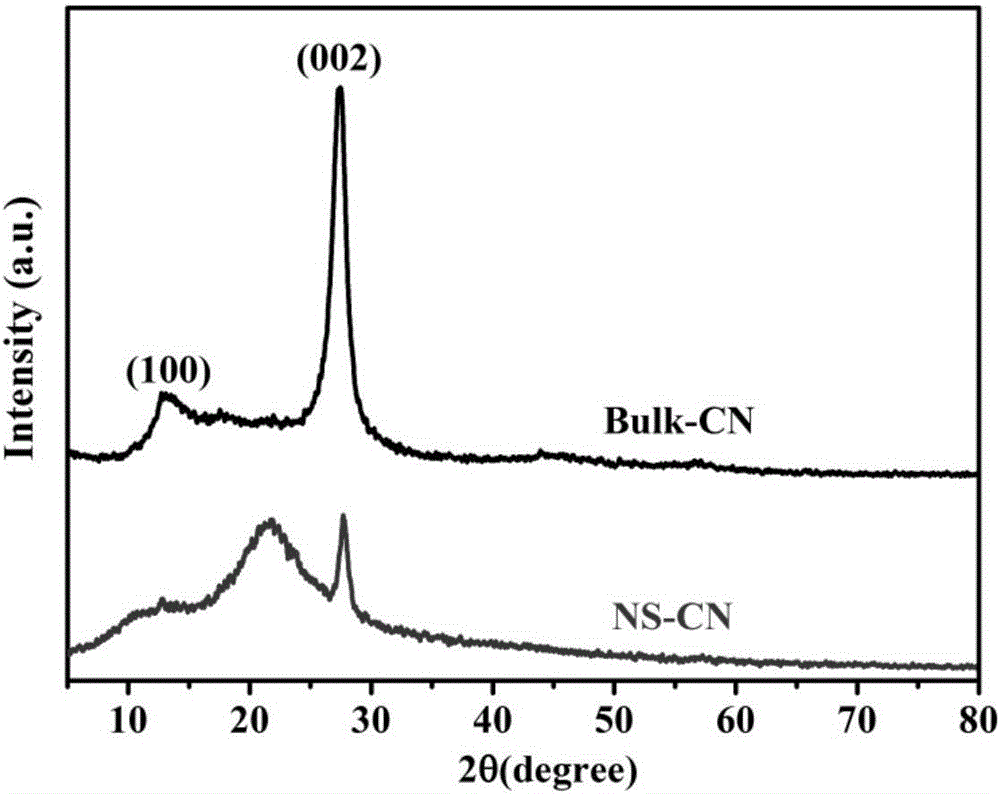

[0038] 2) Preparation of bulk graphitic carbon nitride (g-C 3 N 4 ) Photocatalyst material: move the white precipitate obtained in step 1) into a crucible, then place the crucible in a muffle furnace to raise the temperature to 550°C at a heating rate of 20°C / min, keep it warm for 3h, and obtain a light yellow color after cooling solid;

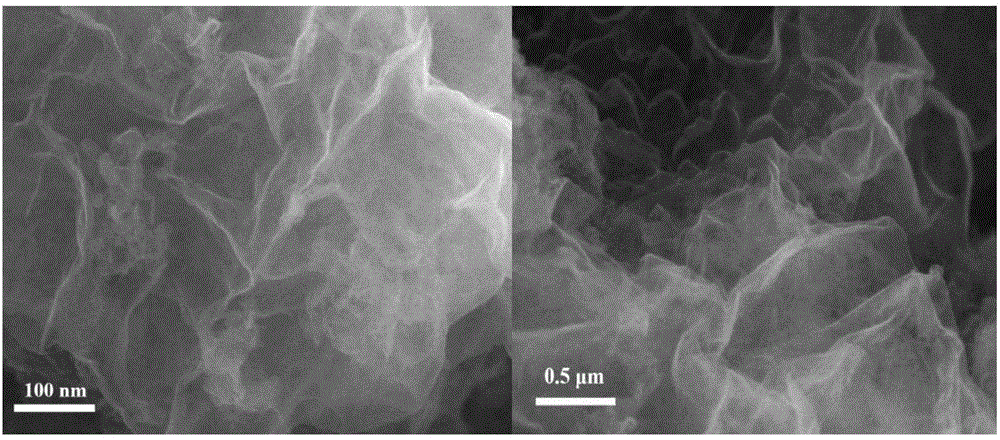

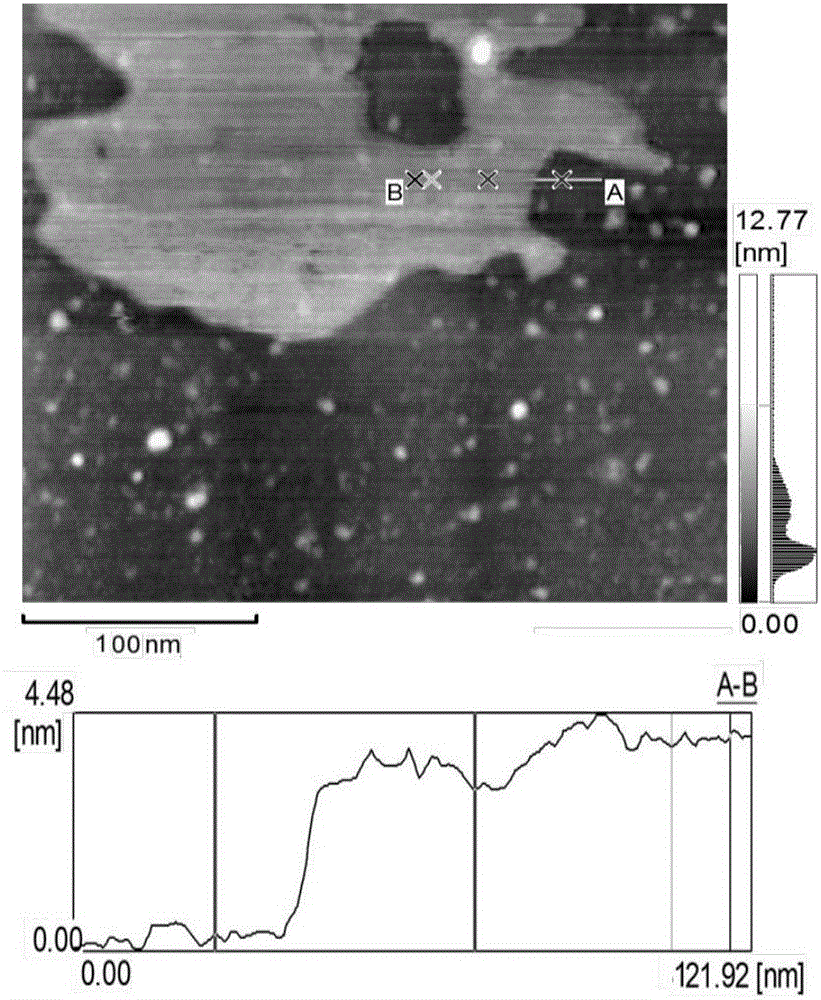

[0039] 3) Preparation of graphitic carbon nitride (g-C 3 N 4 ) photocatalyst material superfine powder: the pale yellow bulk graphite phase carbon nitride (g-C) gained in step 2) 3 N 4 ) is placed in a beaker, and a certain amount of alcohol is added under stirring conditions to form an emulsion with a concentration of 1 g / ml, and then the emulsion is placed in a ball mill for ball mill...

Embodiment 2

[0069] In Example 2, the concentration of nitric acid to treat the precursor was changed. When 0.1M nitric acid was used to treat the melamine precursor, a white flocculent precipitate was obtained. This type of precipitate has poor crystallization performance, and the carbon nitride powder obtained after calcination has There are too many components of polymerization, which is not good for further thinning.

Embodiment 3

[0081] 1) Precursor treatment: Dissolve melamine solid in anhydrous ethanol solution to form a clear solution, then add 0.5M nitric acid solution dropwise, a white precipitate is formed, then filter the white precipitate and vacuum dry it for later use;

[0082] 2) Preparation of bulk graphitic carbon nitride (g-C 3 N 4 ) Photocatalyst material: move the white precipitate obtained in step 1) into a crucible, then place the crucible in a muffle furnace to raise the temperature to 530°C at a heating rate of 20°C / min, keep it warm for 4h, and obtain a light yellow color after cooling solid;

[0083] 3) Preparation of graphitic carbon nitride (g-C 3 N 4 ) photocatalyst material superfine powder: the pale yellow bulk graphite phase carbon nitride (g-C) gained in step 2) 3 N 4 ) is placed in a beaker, and a certain amount of alcohol is added under stirring conditions to form an emulsion with a concentration of 1.5 g / ml, and then the emulsion is placed in a ball mill for ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com