Antibacterial master batch and application thereof

A technology of antibacterial masterbatch and graphene, which is applied in the field of antibacterial masterbatch and its application, can solve the problems of susceptibility to bacterial contamination and lack of antibacterial properties, and achieve the effect of inhibiting bacterial growth and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

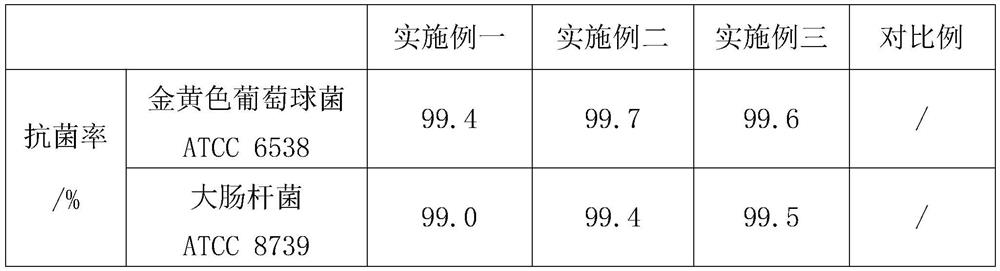

Embodiment 1

[0025] An antibacterial masterbatch, comprising the following raw materials in parts by weight: 70 parts by weight of polypropylene resin, 3 parts by weight of graphene loaded with nano-silver, 1 part by weight of polyvinylpyrrolidone, and 0.4 parts by weight of calcium stearate. The preparation process of the antibacterial masterbatch is as follows: Weigh the raw materials in various parts by weight, add them into a high-speed mixer to fully mix them evenly, and then melt and extrude the mixture through a twin-screw extruder at high temperature to obtain antibacterial masterbatches. Set the process parameters of the twin-screw extruder. The temperatures in each zone from the feeding port to the outlet of the machine head are 175-185°C, 195-210°C, 195-210°C, 185-200°C, and 200-210°C. Antibacterial masterbatches can be prepared by melt granulation within the temperature range. The specific process parameters of the twin-screw extruder in this example are set as follows: the tem...

Embodiment 2

[0033] A kind of antibacterial masterbatch, comprise each raw material of following weight part: 80 weight parts polypropylene resin, the graphene of 5 weight parts loading nano-silver, 2 weight parts N, N'-ethylene bis stearamide, 0.6 weight part hard Zinc fatty acid. The preparation process of the antibacterial masterbatch is as follows: Weigh the raw materials in various parts by weight, add them into a high-speed mixer to fully mix them evenly, and then melt and extrude the mixture through a twin-screw extruder at high temperature to obtain antibacterial masterbatches. The specific process parameters of the twin-screw extruder are set as follows: the temperatures of each zone from the feeding port to the outlet of the die head are 180°C, 200°C, 205°C, 195°C, and 205°C.

[0034] The preparation process of the graphene loaded with nano-silver is as follows:

[0035] S1, preparation of modified graphene oxide:

[0036] Disperse graphene oxide in deionized water, the amount ...

Embodiment 3

[0040] An antibacterial masterbatch, comprising the following raw materials in parts by weight: 90 parts by weight of polypropylene resin, 6 parts by weight of graphene loaded with nano-silver, 3 parts by weight of polyvinylpyrrolidone, and 0.8 parts by weight of silicone. The preparation process of the antibacterial masterbatch is as follows: Weigh the raw materials in various parts by weight, add them into a high-speed mixer to fully mix them evenly, and then melt and extrude the mixture through a twin-screw extruder at high temperature to obtain antibacterial masterbatches. The specific process parameters of the twin-screw extruder are set as follows: the temperatures in each zone from the feeding port to the exit of the die are 185°C, 210°C, 210°C, 200°C, and 210°C.

[0041] The preparation process of the graphene loaded with nano-silver is as follows:

[0042] S1, preparation of modified graphene oxide:

[0043] Disperse graphene oxide in deionized water, the amount of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com