Lignin functionalized modified graphene and preparation method thereof

A technology of lignin and functionalization, applied in the field of lignin-functionalized modified graphene and its preparation, can solve the problems of easy agglomeration and poor dispersibility of graphene, and achieve high carbon content, excellent anti-corrosion performance, and a wide range of sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Graphene oxide nanosheets were prepared by the improved Hummers method, and a uniform dispersion was obtained after step-by-step centrifugal washing and ultrasonic dispersion. The solid content of graphene oxide was measured to be 3.2 mg / mL;

[0028] (2) Take 17 mL (54.4 mg) of the dispersion in step (1) in 50 mL of deionized water, add 10 mg of sodium lignosulfonate, and ultrasonically disperse for 0.5 hours to obtain a lignosulfonic acid-graphene oxide mixed solution;

[0029] (3) Add 50 mg of polyaniline sulfonate to the sodium lignosulfonate-graphene oxide mixed solution obtained in step (2), stir continuously to make it fully and uniformly contact, then react at 0 °C for 6 hours, and dry to constant weight , that is, lignin functionalized modified graphene powder is obtained, and its SEM image is as follows figure 1 shown. Depend on figure 1 It can be seen that the lignin-functionalized modified graphene has good dispersion and no agglomeration phenomenon occ...

Embodiment 2

[0031] (1) Graphene oxide nanosheets were prepared by the improved Hummers method, and a uniform dispersion was obtained after step-by-step centrifugal washing and ultrasonic dispersion. The solid content of graphene oxide was measured to be 3.2 mg / mL;

[0032] (2) Take 10 mL (32 mg) of the dispersion from step (1) in 50 mL of 0.01 mol / L ammonia solution, add 5 mg of enzymatic lignin, and ultrasonically disperse for 0.5 hours to obtain enzymatic lignin-graphite oxide Alkene mixed solution;

[0033] (3) Add 30 mg of sulfonated diphenylamine polymer to the enzymatic lignin-graphene oxide mixed solution obtained in step (2), stir continuously to make it fully and uniformly contact, then react at 5 °C for 4 hours, and dry to constant temperature. Heavy, that is, to obtain lignin functionalized modified graphene powder, its SEM picture is as follows figure 2 shown. Depend on figure 2 It can be seen that the modified molecules are effectively inserted between the graphene sheet...

Embodiment 3

[0035] (1) Graphene oxide nanosheets were prepared by the improved Hummers method, and a uniform dispersion was obtained after step-by-step centrifugal washing and ultrasonic dispersion. The solid content of graphene oxide was measured to be 5 mg / mL;

[0036] (2) Take 6 mL (30 mg) of the dispersion from step (1) in 50 mL of 0.01 mol / L sodium bicarbonate solution, add 3 mg of enzymatic lignin, and ultrasonically disperse for 1 hour to obtain enzymatic lignin-oxidized Graphene mixed solution;

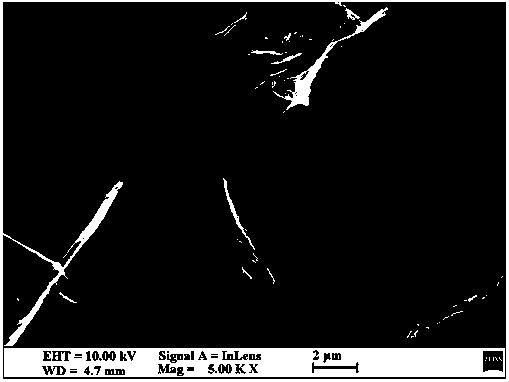

[0037] (3) Add 80 mg polyaniline / lignosulfonic acid complex to the enzymatic lignin-graphene oxide mixed solution obtained in step (2), stir continuously to make it fully and uniformly contact, and then react at 1 °C for 5 hours, Dry to constant weight to obtain lignin functionalized modified graphene powder, its SEM picture is as follows image 3 shown. Depend on image 3 It can be seen that the obtained lignin-functionalized modified graphene has good dispersion and no agglomeration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com