Preparation method of compact corrosion-resistant low-radiation film material

A low-E film and corrosion-resistant technology, applied in the field of film materials, can solve the problems of poor corrosion resistance of low-E film, achieve the effects of weakening Van der Waals force, improving corrosion resistance, and preventing oxidation erosion

Inactive Publication Date: 2018-11-20

FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved by the present invention: Aiming at the problem of poor corrosion resistance of th

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

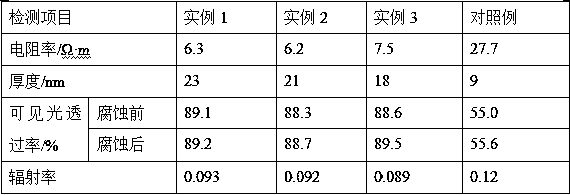

The invention relates to a preparation method of a compact corrosion-resistant low-radiation film material and belongs to the technical field of film materials. The preparation method provided by theinvention has the benefits that the effects of preparing a tin dioxide material and acting as a steric hindrance through coating layers formed by coating the surfaces of the colloidal particles with adispersing agent are adopted, so that the van der Waals force between the particles is greatly weakened; meanwhile, a target material is prepared by compounding tin dioxide and silica sol; a penetrating structure is formed in the silica sol by the tin oxide material, and during the use, TiNx forms an unsaturated bond and can be slowly combined with O in air to form Ti-N-O and Ti-O bonds; the surface of a TiNx thin film is compact because of expansion in the TiNx thin film and pressure stress produced on the surface; the result has a closed effect on the surface of the coating layer, which canprevent the further oxidation erosion and improve the corrosion resistance of the material. The sputtering preparation in the invention needs to not only control the distance between a base materialand the target material as well as the nitrogen flow, but also control the sputtering power of a modified target material; and after being sputtered, a modified thin film is pressurized and introducedwith nitrogen, and the flow rate is adjusted.

Description

technical field [0001] The invention relates to a preparation method of a dense corrosion-resistant low-emissivity membrane material, which belongs to the technical field of membrane materials. Background technique [0002] Due to its outstanding contribution to building energy saving, low-e glass has been widely used in western countries. With my country's continuous emphasis on energy-saving and environmental protection technologies, my country's demand for low-e glass has gradually increased. However, western countries have monopolized the production of low-e glass. In order to obtain high-performance low-e glass at a lower price, we urgently need to develop low-e glass with independent intellectual property rights and excellent performance. At the same time, in order to be more conducive to the large-scale industrial production of low-e glass, we also need to explore new film structures, select new materials and new processes, so that Chinese people can use economical l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03C17/22

CPCC03C17/225C03C2218/155

Inventor 胡次兵韩桂林朱华

Owner FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com