Hood for circulating fluidized bed boiler

A circulating fluidized bed and air cap technology, applied in the field of air cap structure, can solve problems such as poor fluidization effect, clogging of ash particles, air cap wear, etc., and achieve the effects of optimizing the fluidization effect, preventing air hole clogging and convenient air outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

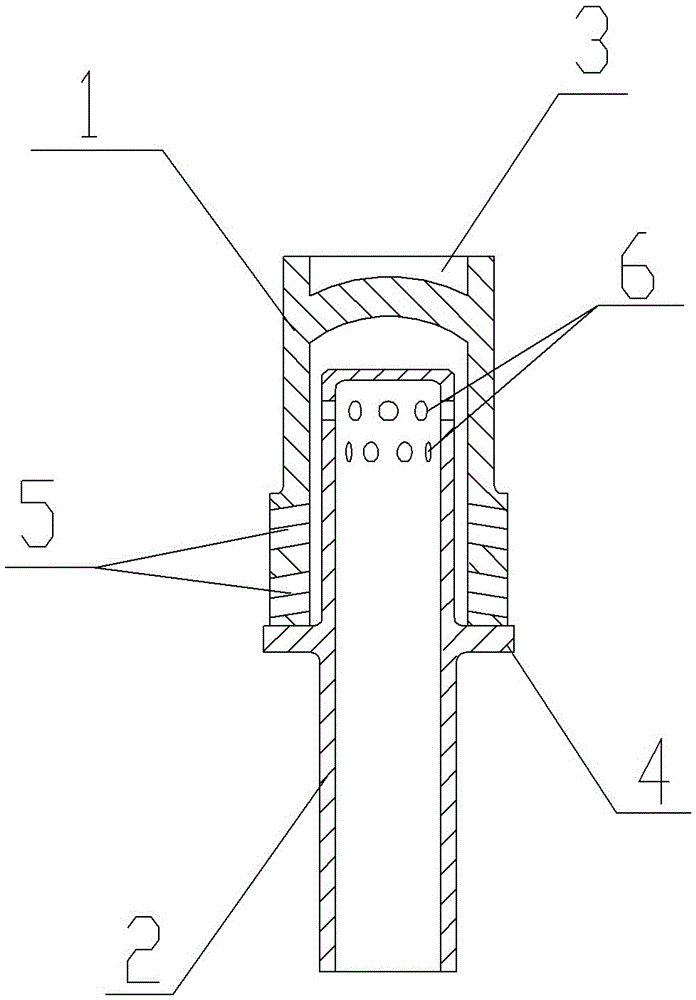

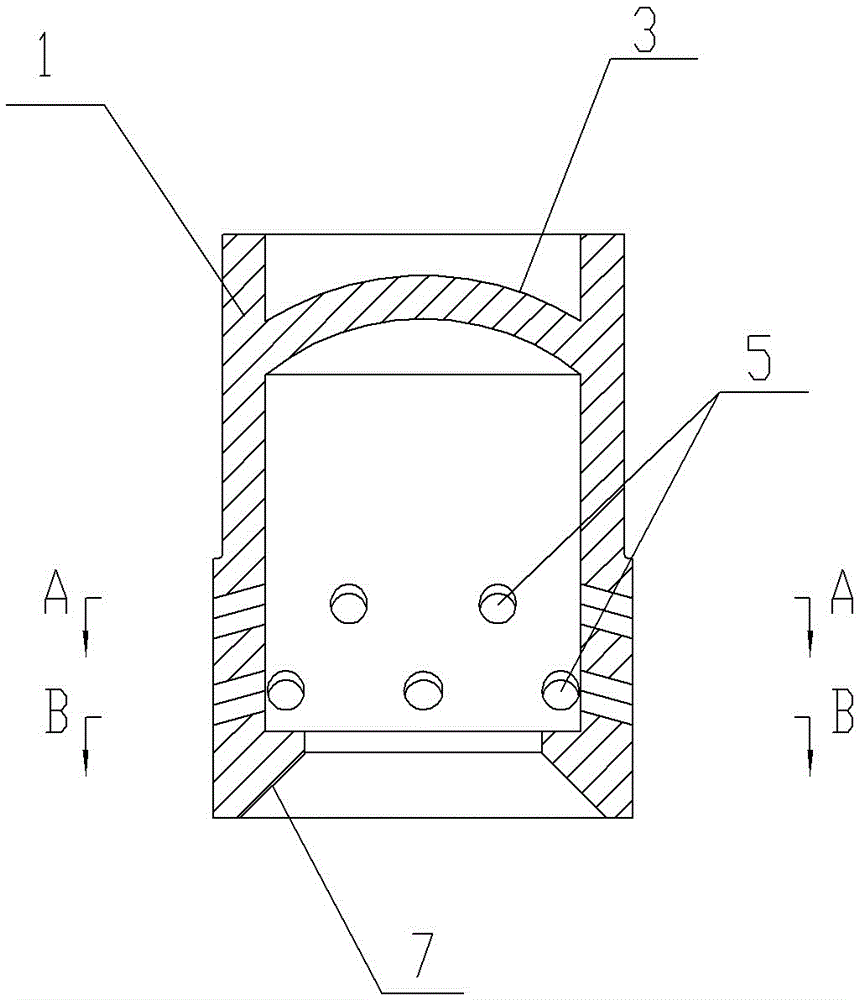

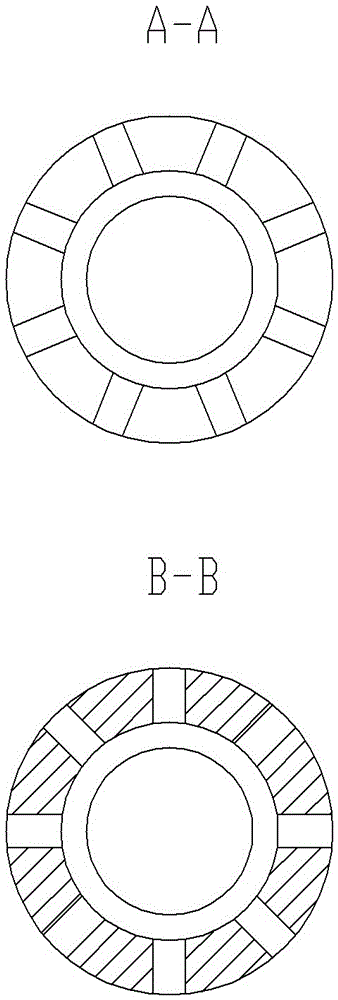

[0016] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a hood for a circulating fluidized bed boiler includes a hood head 1 and a connecting pipe 2, the hood head 1 is set on the upper end of the connecting pipe 2, the bottom of the hood head 1 is fixedly connected to the boss 4 of the connecting pipe 2, and the connecting pipe 2 The upper side wall is provided with two rows of connecting air holes 6 along the circumferential direction, and there may be more rows. The lower side wall of the hood head 1 is provided with two rows of air outlet holes 5 along the circumferential direction. The hole 6 and the adjacent two rows of air outlet holes 5 of the hood are arranged in a staggered manner, the best is a row of eight connecting air holes 6 and eight air outlet holes 5 of the hood, and the air outlet holes 5 of the hood are inclined downward Arrangement, the angle of downward inclination is 10 °-20 °, the best is 15 °; the top of the hood head 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com