Method for fluidized catalytic decomposition of gypsum

A fluidized catalysis, gypsum technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problems of high energy consumption, low product added value, slow decomposition rate, etc. The effect of high value and fast decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

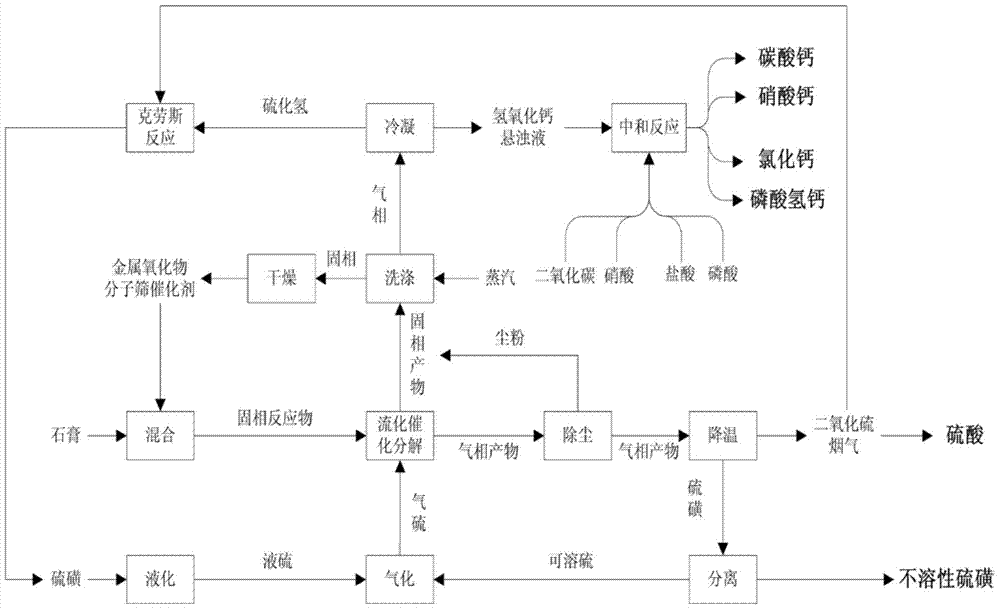

Image

Examples

Embodiment 1

[0028] (1), powdered natural gypsum or anhydrite raw material and iron or scandium oxide molecular sieve catalyst particles are mixed evenly according to the mass ratio of 1:1, and then added to the fluidized reactor;

[0029] (2) Sulfur gas after sulfur gasification of the reducing agent enters from the bottom of the fluidized reactor at a mass ratio of 2:1 to gypsum powder and a mole fraction of the gas phase of 10%, and contacts with the material in (1), at 550°C To decompose gypsum, the residence time of the material is 1min, and the decomposition rate of gypsum is 60%.

[0030] (3), the solid phase obtained by the fluidized catalytic decomposition reaction (calcium sulfide mass fraction is 40% powder and catalyst particles) is steam washed, and the solid phase after washing is a metal oxide molecular sieve catalyst, after drying at 120 ° C Return to step (1) for recycling. The gas phase is first condensed to obtain a suspension with a mass fraction of calcium hydroxide o...

Embodiment 2

[0033] (1), powdery desulfurization gypsum or salt gypsum raw material and titanium or manganese oxide molecular sieve catalyst particles are mixed evenly according to the mass ratio of 10:1, and then added to the fluidized reactor;

[0034] (2) Sulfur gas after gasification of sulfur as a reducing agent enters from the bottom of the fluidized reactor at a mass ratio of 3:1 to gypsum powder and a mole fraction of the gas phase of 40%, and contacts with the material in (1), at 600°C Decompose gypsum, the material residence time is 10min, and the gypsum decomposition rate is 80%.

[0035] (3), the solid phase obtained by the fluidized catalytic decomposition reaction (calcium sulfide mass fraction is 70% powder and catalyst particles) is steam washed, and the solid phase after washing is a metal oxide molecular sieve catalyst, after drying at 150 ° C Return to step (1) for recycling. The gas phase is first condensed to obtain a suspension with a mass fraction of calcium hydroxi...

Embodiment 3

[0038] (1), powdery titanium dioxide by-product gypsum raw material and vanadium or chromium oxide molecular sieve catalyst particles are mixed evenly according to the mass ratio of 5:1, and added to the fluidized reactor;

[0039] (2) Sulfur gas after sulfur gasification of the reducing agent enters from the bottom of the fluidized reactor at a mass ratio of 6:1 to gypsum powder and a mole fraction of the gas phase of 50%, and contacts with the material in (1), at 620°C Decompose gypsum, the material residence time is 20min, and the gypsum decomposition rate is 90%.

[0040] (3), the solid phase obtained by the fluidized catalytic decomposition reaction (calcium sulfide mass fraction is 95% powder and catalyst particles) is steam washed, and the solid phase after washing is a metal oxide molecular sieve catalyst, after drying at 180 ° C Return to step (1) for recycling. The gas phase is first condensed to obtain a suspension with a mass fraction of calcium hydroxide of 45%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com