Corrosion-resistant ferronickel electrode and preparation method and application thereof

An electrode, nickel-iron technology, applied in the field of corrosion-resistant nickel-iron electrode and its preparation and application, can solve the problems of low corrosion resistance stability, poor activity, stability and corrosion resistance, poor stability, etc. Achieve the effect of improving corrosion resistance, improving activity and stability, and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

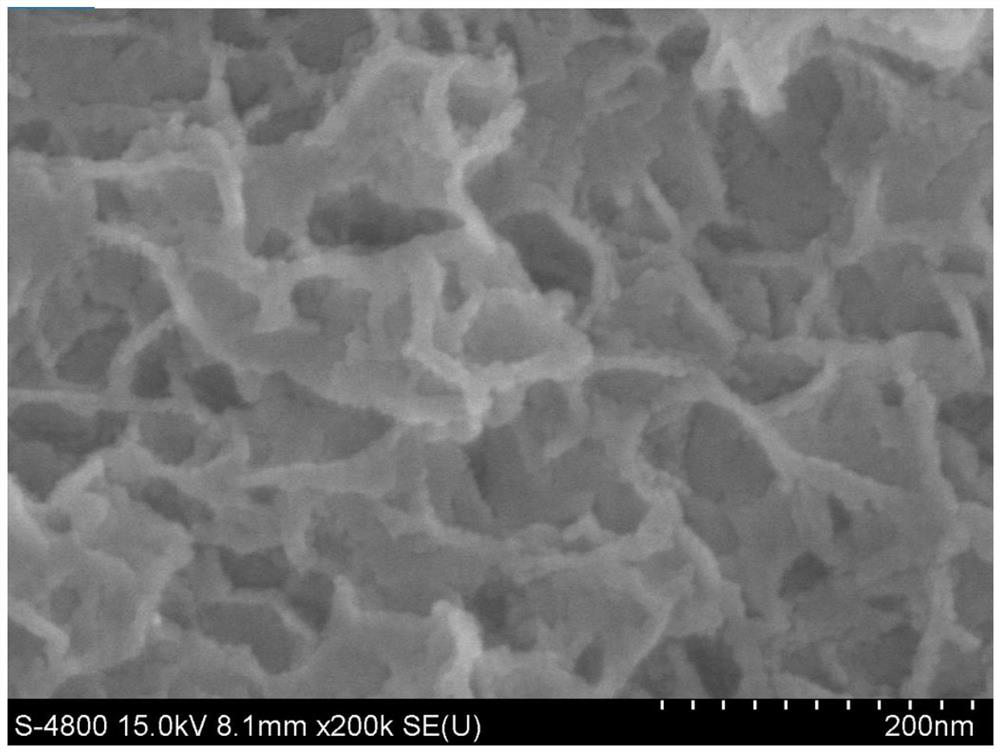

[0068] (1) Cut 0.5cm×0.4cm foamed nickel-iron (iron content is 20%), and ultrasonically sonicate each in acetone, ethanol and deionized water for 20 min in turn to obtain a pretreated foamed nickel-iron substrate.

[0069] (2) Weigh 0.0248 g (0.1 mmol) of sodium thiosulfate and 15 mg of bis-decyl dimethyl ammonium acetate and dissolve in 20 mL of ethylene glycol, and magnetically stir at room temperature for 30 min to dissolve, forming a transparent and colorless solution.

[0070] (3) Transfer the obtained transparent and colorless solution to a 100 mL hydrothermal kettle, place the pretreated foamed nickel-iron substrate in the hydrothermal kettle, tighten the hydrothermal kettle, and place it in a 180°C oven to maintain a constant temperature for 24h;

[0071] (4) After the hydrothermal kettle was cooled down to room temperature, the hydrothermal kettle was taken out and opened, the samples after hydrothermal were cleaned with deionized water and ethanol, and then placed in ...

Embodiment 2

[0077] (1) Cut out 0.5cm×0.4cm foamed nickel-iron (iron content is 40%), and ultrasonically sonicate each in acetone, ethanol and deionized water for 20 min in turn to obtain a pretreated foamed nickel-iron substrate.

[0078] (2) Weigh 0.0248 g (0.1 mmol) of sodium thiosulfate and 15 mg of bis-decyl dimethyl ammonium acetate and dissolve in 20 mL of ethylene glycol, and magnetically stir at room temperature for 30 min to dissolve, forming a transparent and colorless solution.

[0079] (3) Transfer the obtained transparent and colorless solution to a 100 mL hydrothermal kettle, place the pretreated foamed nickel-iron substrate in the hydrothermal kettle, tighten the hydrothermal kettle, and place it in a 180°C oven to maintain a constant temperature for 24h;

[0080] (4) After the hydrothermal kettle was cooled to room temperature, the hydrothermal kettle was taken out and opened, and the sample after hydrothermal was cleaned with deionized water and ethanol, and then placed in...

Embodiment 3

[0084] (1) Cut out 0.5cm×0.4cm foamed nickel-iron (iron content is 60%), and ultrasonically sonicate each in acetone, ethanol and deionized water for 20 min in turn to obtain a pretreated foamed nickel-iron substrate.

[0085] (2) Weigh 0.0248 g (0.1 mmol) of sodium thiosulfate and 15 mg of bis-decyl dimethyl ammonium acetate and dissolve in 20 mL of ethylene glycol, and magnetically stir at room temperature for 30 min to dissolve, forming a transparent and colorless solution.

[0086] (3) Transfer the obtained transparent and colorless solution to a 100 mL hydrothermal kettle, place the pretreated foamed nickel-iron substrate in the hydrothermal kettle, tighten the hydrothermal kettle, and place it in a 180°C oven to maintain a constant temperature for 24h;

[0087] (4) After the hydrothermal kettle was cooled down to room temperature, the hydrothermal kettle was taken out and opened, the samples after hydrothermal were cleaned with deionized water and ethanol, and then placed...

PUM

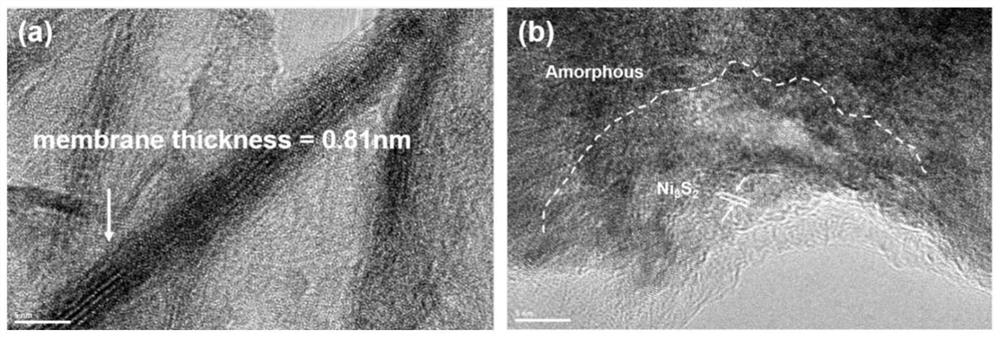

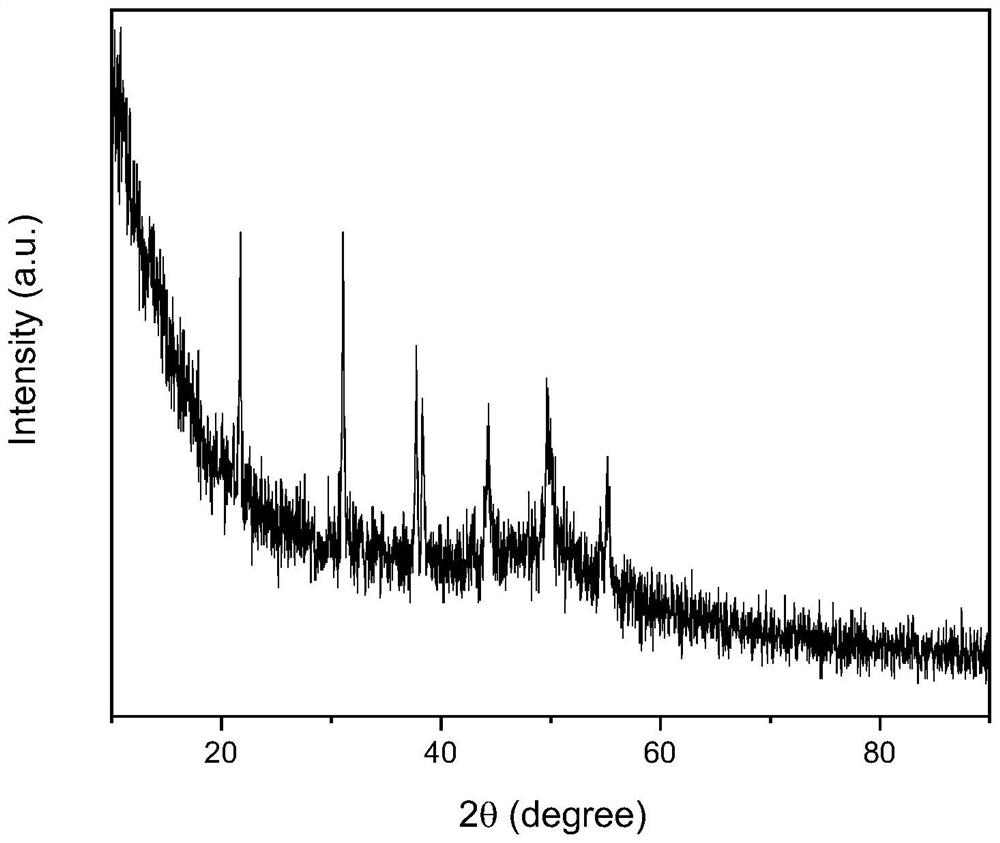

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com