Magnetic gold-cobalt composite catalyst as well as preparation method and application thereof

A composite and catalyst technology, which is applied in the field of magnetic gold-cobalt composite catalyst and its preparation, can solve the problems of polluting the environment and difficult recovery of the catalyst, and achieve the effects of high conversion rate, efficient electron transfer effect and high catalytic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a preparation method of the magnetic gold-cobalt composite catalyst described in the above technical scheme, comprising the following steps:

[0039] Mixing the water-soluble gold precursor, the water-soluble cobalt precursor, the borohydride salt and water, adjusting the pH value to 5-10, and carrying out the precipitation-reduction reaction in sequence to obtain the catalyst precursor;

[0040] The catalyst precursor is subjected to a hydrogen reduction reaction to obtain a magnetic gold-cobalt composite catalyst.

[0041] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0042] In the invention, the water-soluble gold precursor, the water-soluble cobalt precursor, borohydride salt and water are mixed, and the precipitation-reduction reaction is carried out to obtain the catalyst precursor.

[0043] In the present invention, the...

Embodiment 1

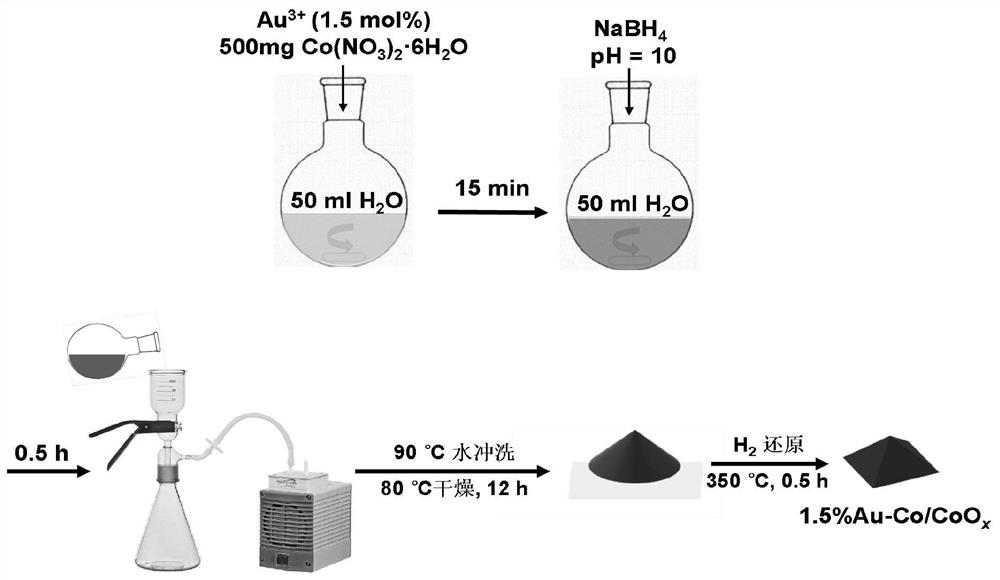

[0066] use figure 1 The preparation flow chart shown prepares magnetic gold-cobalt composite catalyst;

[0067] (1) Add 1 mL of HAuCl with a concentration of 5 mg / mL 4 4H 2 O solution and 0.5g Co(NO 3 ) 2 ·6H 2 O was placed in a 250mL round-bottomed flask, added 50mL deionized water and stirred for 15min, then added dropwise the newly prepared NaBH with a concentration of 1mg / mL 4 Aqueous solution to a pH value of 10, under the condition of avoiding light and stirring for precipitation-reduction reaction for 2 hours, suction filtration, suction filtration and washing with 1.5L deionized water at a temperature of 90°C until the filtrate is a colorless transparent liquid, and then placed in an oven at 80°C dry in medium for 12 hours to obtain the catalyst precursor; wherein, the filter membrane used for suction filtration is an organic phase filter membrane with a specification of 50mm×0.08μm~50mm×0.2μm;

[0068] (2) The catalyst precursor was subjected to a hydrogen reduc...

Embodiment 2

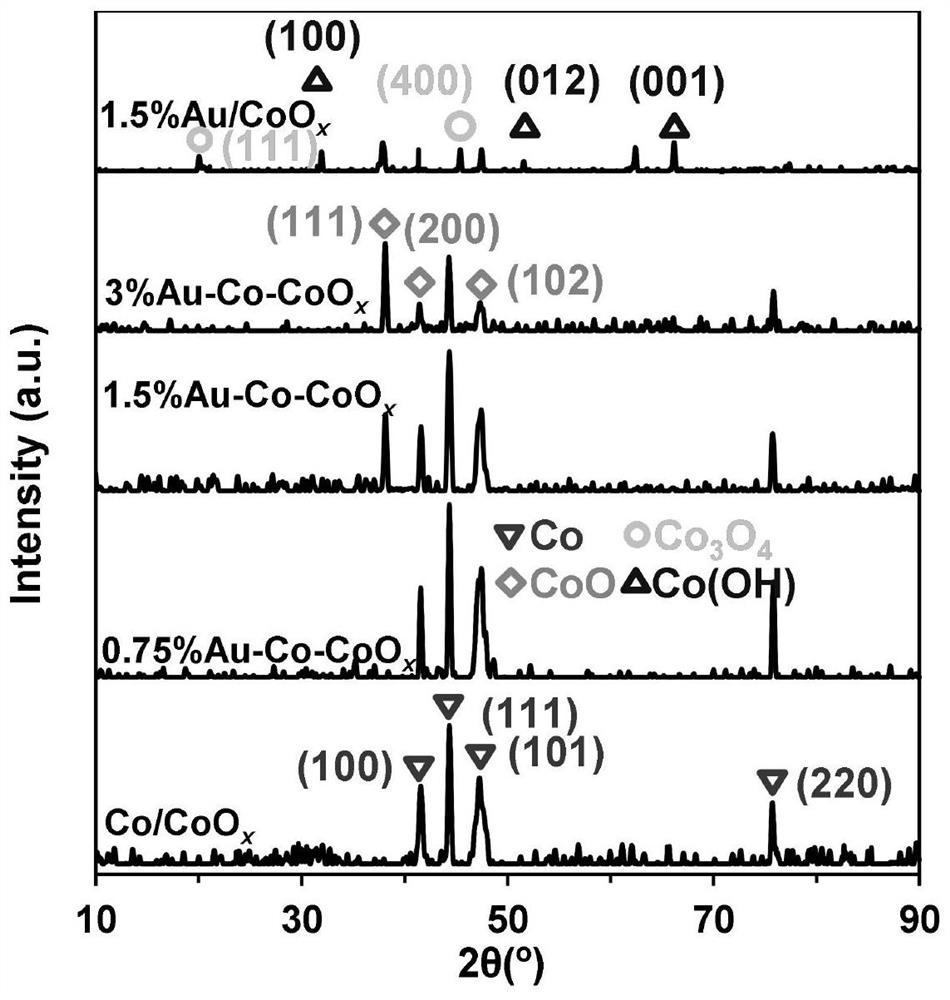

[0070] Prepare the magnetic gold-cobalt composite catalyst according to the method of Example 1, the difference from Example 1 is that HAuCl in step (1) 4 4H 2 The volume of the O solution is 2mL, and the magnetic gold-cobalt composite catalyst (abbreviated as 3%Au-Co / CoO x , where x=1.25).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com