Baffled MBBR biochemical system of flexible suspended filler

A technology of suspended filler and biochemical system, which is applied in the field of MBBR biochemical system, can solve the problems of dead sludge of filler, increase of filler biomass, uneven fluidization of suspended carrier, etc., to solve easy clogging, reduce water shear force, improve The effect of the biological treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

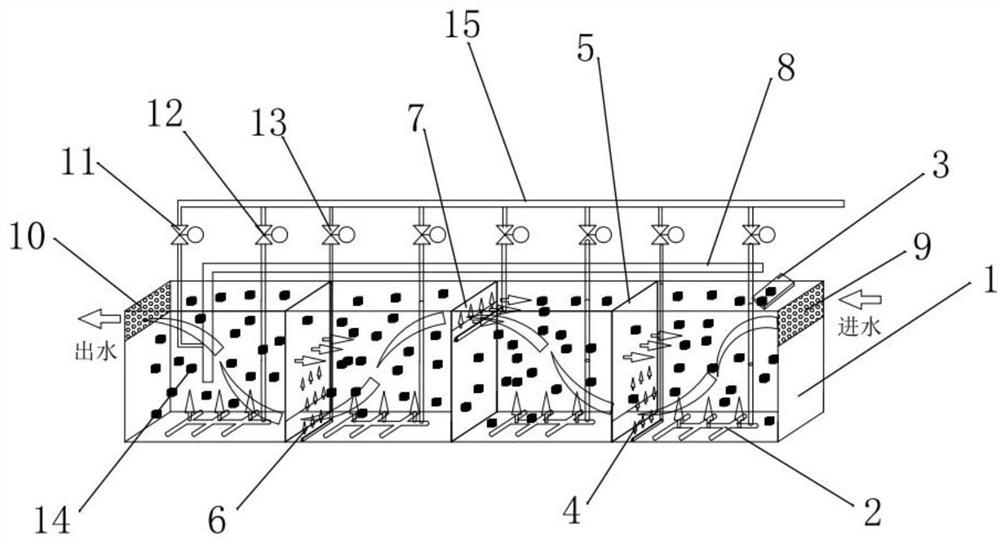

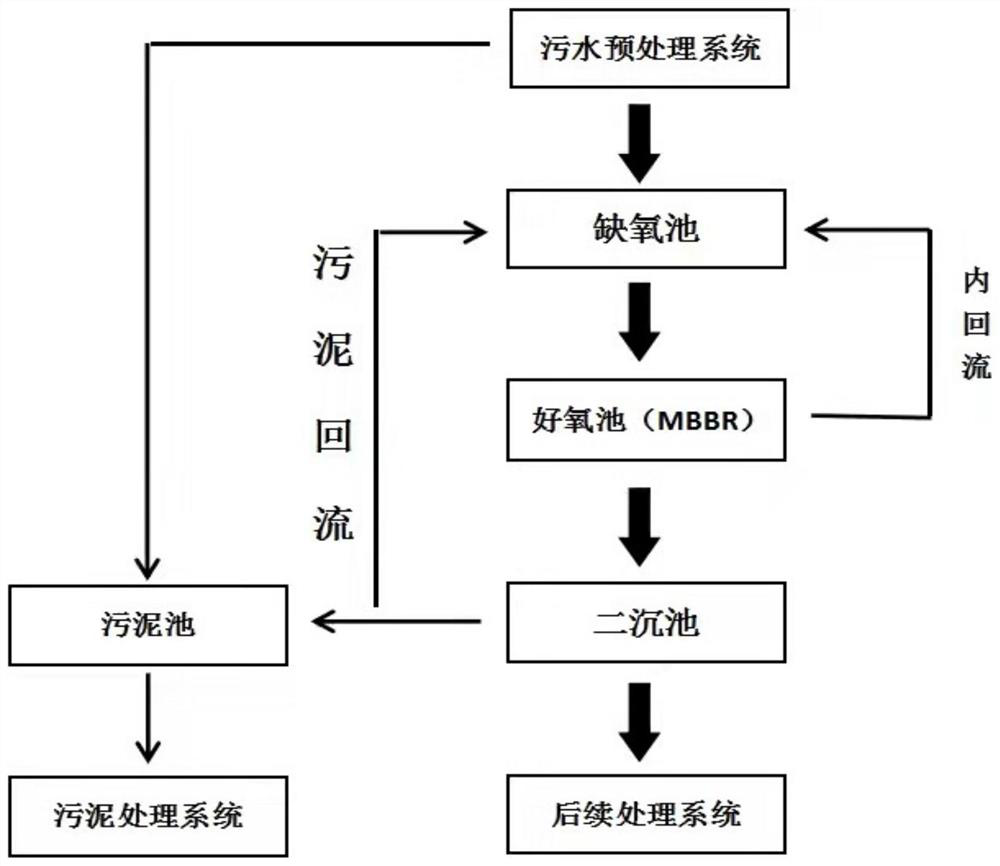

[0033] A flushing MBBR system of a flexible suspension, including: a pool body 1, aeration line 2, a main transporting device 15, a gas knife 4, an air reflow device, and a collision plate 3; the pool body 1 is a single row, the pool The three sets of baffles 5 are provided in the body 1 to four sets of baffle 14, and the baffle 5 is sequentially set in sequential sequential sequential sequential sequential sequential order, so that the liquid forms up and down in the pool body 1; The length of the water port 6 and the uproots 5 is equal to the baffle 5. The strip-shaped air knife 4 is provided at the liquid opening 5 outlet and the main ventilation device 15 is connected by the air knife control valve 13, and the air knife 4 forms upward in the effluent wall 5 outlet and flows to the vertical flow of the liquid to vertical. The flexible suspended filler is passed, and the water intercepting net 10 is provided in the pool body 1 outlet 10, and the water intercepting net 9 is provi...

Embodiment 2

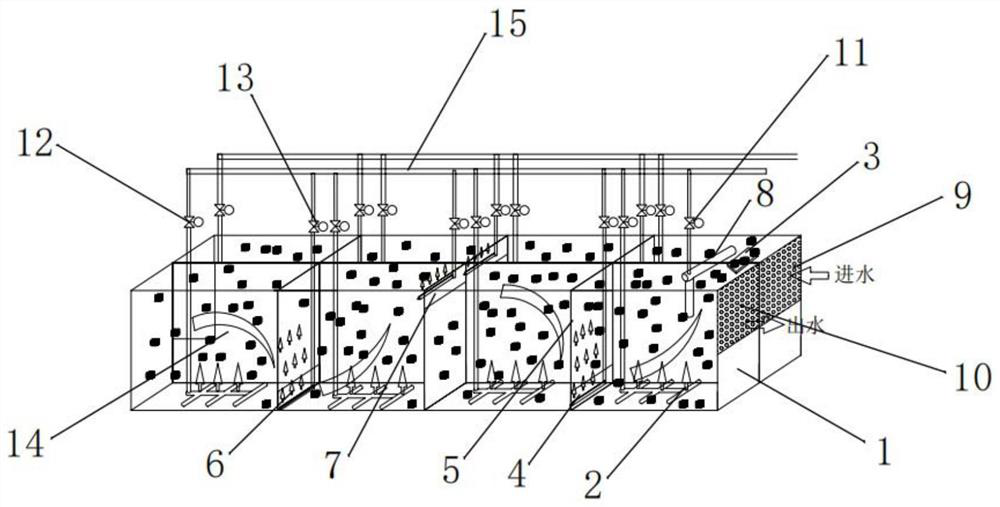

[0037] A flushing MBBR system for flexible suspension filler, including: pool body 1, aeration line 2, main transport gas device 15, air knife 4, air reflow device and collision plate 3; pool body 1 is double-row-series The six sets of baffles 5 are provided in the pool body 1 into a seven sets of baffle 14, and the baffle 15 is in parallel, regarded as a large liquid chamber, and the baffle 5 sequentially sets the water port 6 in sequence. The uproots 7, so that the liquid forms up and down the liquid in the pool body 1; the length of the lower moisture port 6 and the uproots 5 are equal to the baffle 5. The strip-shaped air knife 4 is provided at the liquid opening 5 outlet and the main ventilation device 15 is connected by the air knife control valve 13, and the air knife 4 forms upward in the effluent wall 5 outlet and flows to the vertical flow of the liquid to vertical. The flexible suspended filler is passed, and the water intercepting net 10 is provided in the pool body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com