A plate evaporator

A plate evaporator and substrate technology, applied in evaporator accessories, evaporation, evaporator/condenser, etc., can solve the problems of high cutting cost, high equipment investment cost, and increased equipment control cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

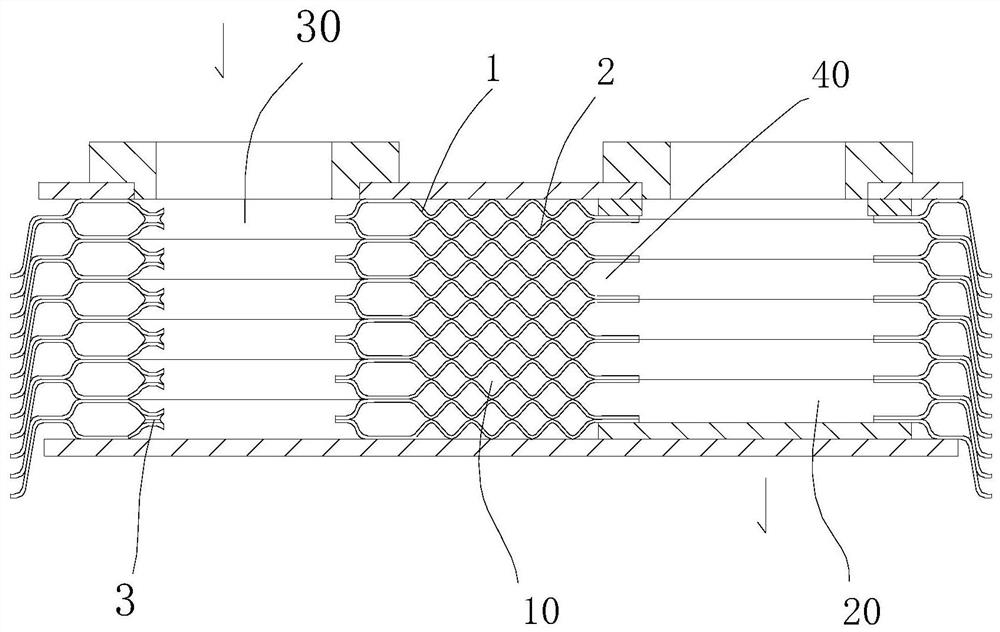

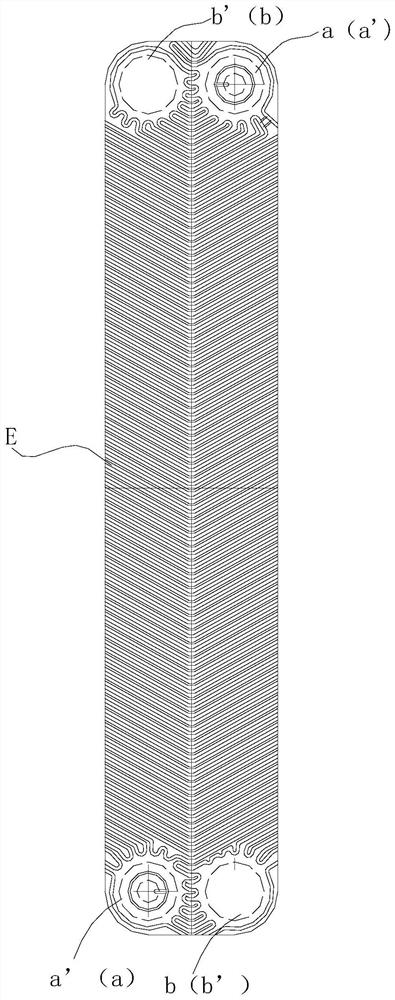

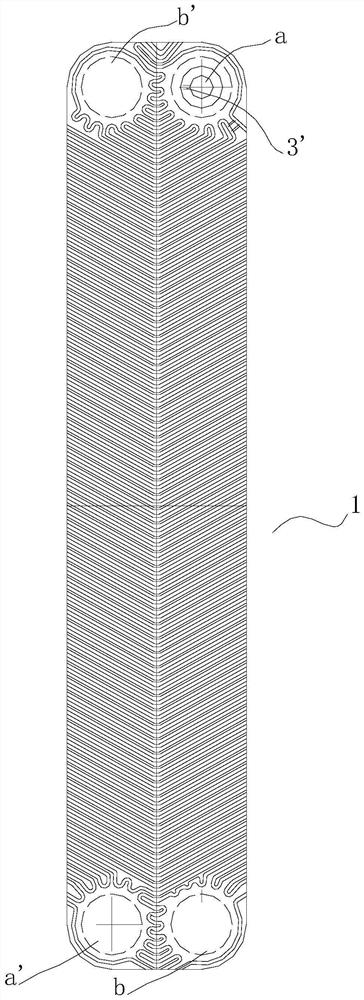

[0040]The main structure of the plate evaporator of the present embodiment is a series of heat exchange plates that are laminated together by the first heat exchange sheet 1 and the second heat exchange sheet 2, and the first heat exchange sheet 1 and the second heat exchange sheet 2 are between Formation of mutually interlocation, isolating heat transfer flow paths, respectively, isolated, respectively. In the first, the first surface 6 of the second heat transfer plate is provided with four corner apertures, including the first in-liquid holes A and the first liquid holes A 'for the flow through flow flow out of the evaporation agent for heat transfer agent. The second liquid hole B and the second liquid hole B 'of the flow flowing out corresponds to the same corner aperture on the thickness direction corresponding to the first in liquid passage 30, the first liquid passage, the first Different liquid passages and second liquid passage 20. The same corner aperture is concave or co...

Embodiment 2

[0044]Based on the plate evaporator according to Example 1, the first and second heat transfer plates may be respectively punched by the center symmetrical same substrate, and the punching means including the first intake / outlet and the second into / outlet. Synchronous stamping operation of a total of four corner apertures within the same. When the second liquid hole and the second liquid hole of the first embodiment are the same, the first and second heat exchange plates may further be further rushing the second into the same substrate, the same substrate of the liquid holes, respectively. Synchronous rolled out the first in / outlet.

[0045]The preparation of the above-mentioned plate evaporator is achieved on a production line.

[0046](1) The continuous feed volume of the copper foil and substrate metal material is prepared;

[0047](2) Copper foil feed: to the copper foil punching punch, in the calculated position punched hole, the left-blank portion covers the recess of the first i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com