Vacuum adsorption disc, polishing machine, polishing method, full-automatic polishing machine system and full-automatic polishing method

A technology of vacuum adsorption and adsorption disk, which is applied in the field of polishing, and can solve the problems of adsorption pad consumables, uneven force of adsorption glass, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

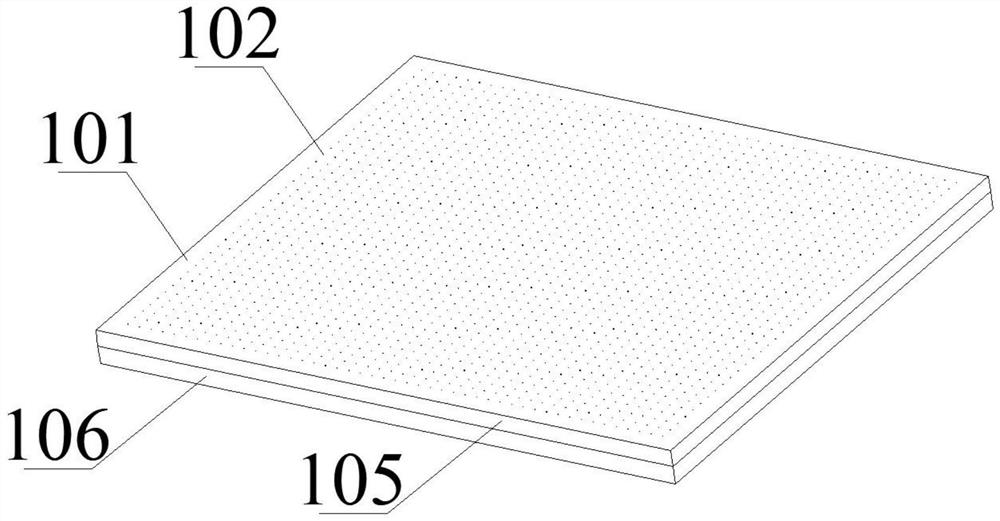

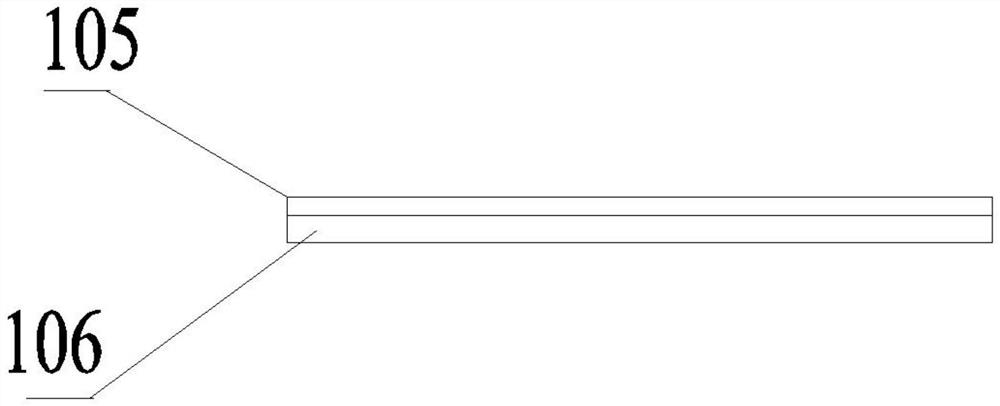

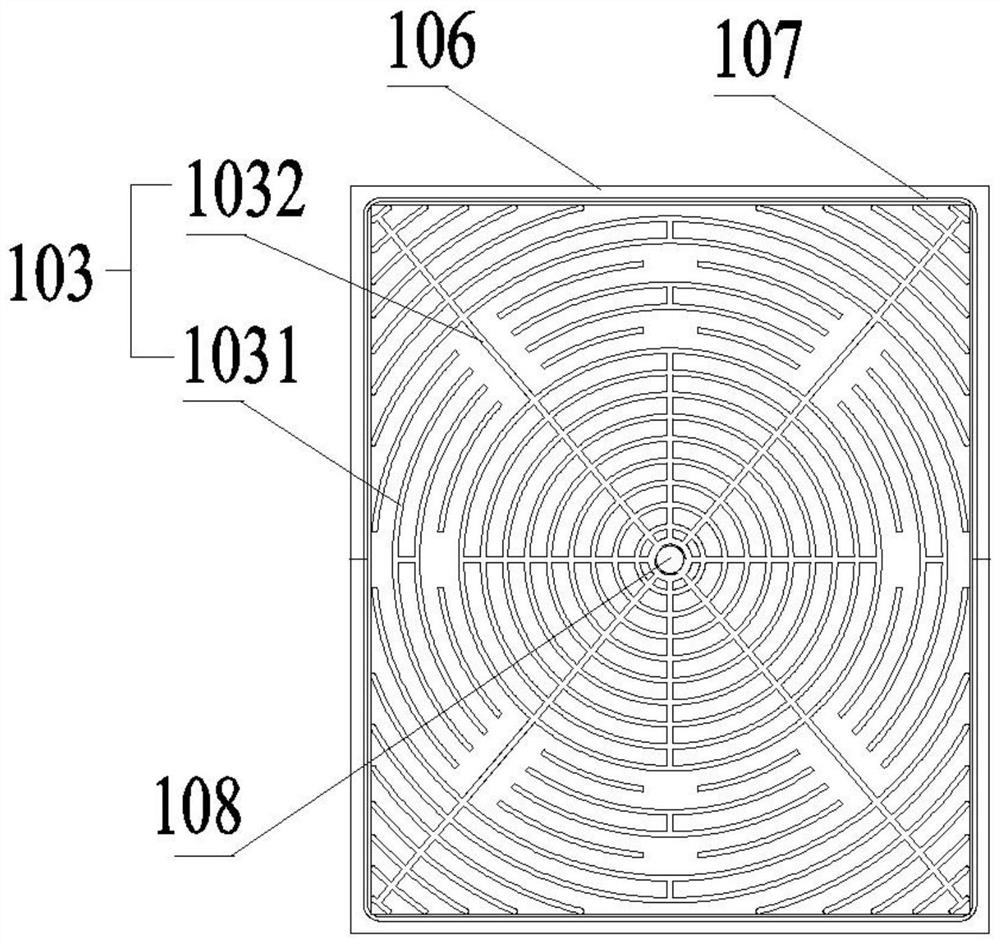

[0064] Such as Figure 1-Figure 5 As shown, the vacuum suction disc that can be used for the polishing machine in this embodiment includes a first suction disc 105 and a second suction disc 106, both of which are hard materials, and the first suction disc 105 It fits closely with the second suction disk 106 and forms a half-closed suction vacuum chamber. The suction vacuum chamber includes the first suction chamber 104 inside the first suction disk 105 and the second suction chamber inside the second suction disk 106. 103, the outer side of the first adsorption plate 105 is set as a polishing piece adsorption surface 101, and the polishing piece adsorption surface 101 is uniformly arranged with adsorption holes 102, and the first adsorption chamber 104 is formed by connecting with each other with a plurality of uniformly arranged first adsorption air channels , and the first adsorption chamber 104 penetrates to the adsorption hole 102; the second adsorption chamber 103 is form...

Embodiment 2

[0101] The vacuum suction disk used in the polishing machine of this embodiment is the same as that of Embodiment 1.

[0102] Such as Figure 13 As shown, the polishing machine with the above-mentioned vacuum suction plate in this embodiment includes a polishing machine body 3, the polishing machine body 3 includes an upper fixed plate 302, and the vacuum adsorption plate is fixed on the upper fixed plate 302.

[0103] In this embodiment, the pressure regulating assembly 2 includes a main shaft 201 and an air pump 202 . The main shaft 201 is provided with a vacuum pipeline 203 .

[0104] In this embodiment, the main shaft 201 includes a first main shaft 2011 and a second main shaft 2012 that are sealed and connected to each other. The lower part of the first main shaft 2011 communicates with the air passage communication hole 108 through the vacuum suction chamber, and the second main shaft 2012 passes through the upper fixed plate 302 It is connected with the first main shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com