Vertical smoke tube exhaust-heat boiler

A waste heat boiler and smoke tube technology, applied in the field of waste heat boilers, can solve the problems of corrosion on the heating surface, difficulty in cleaning ash, burst tubes, etc., and achieve the effect of high-efficiency heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

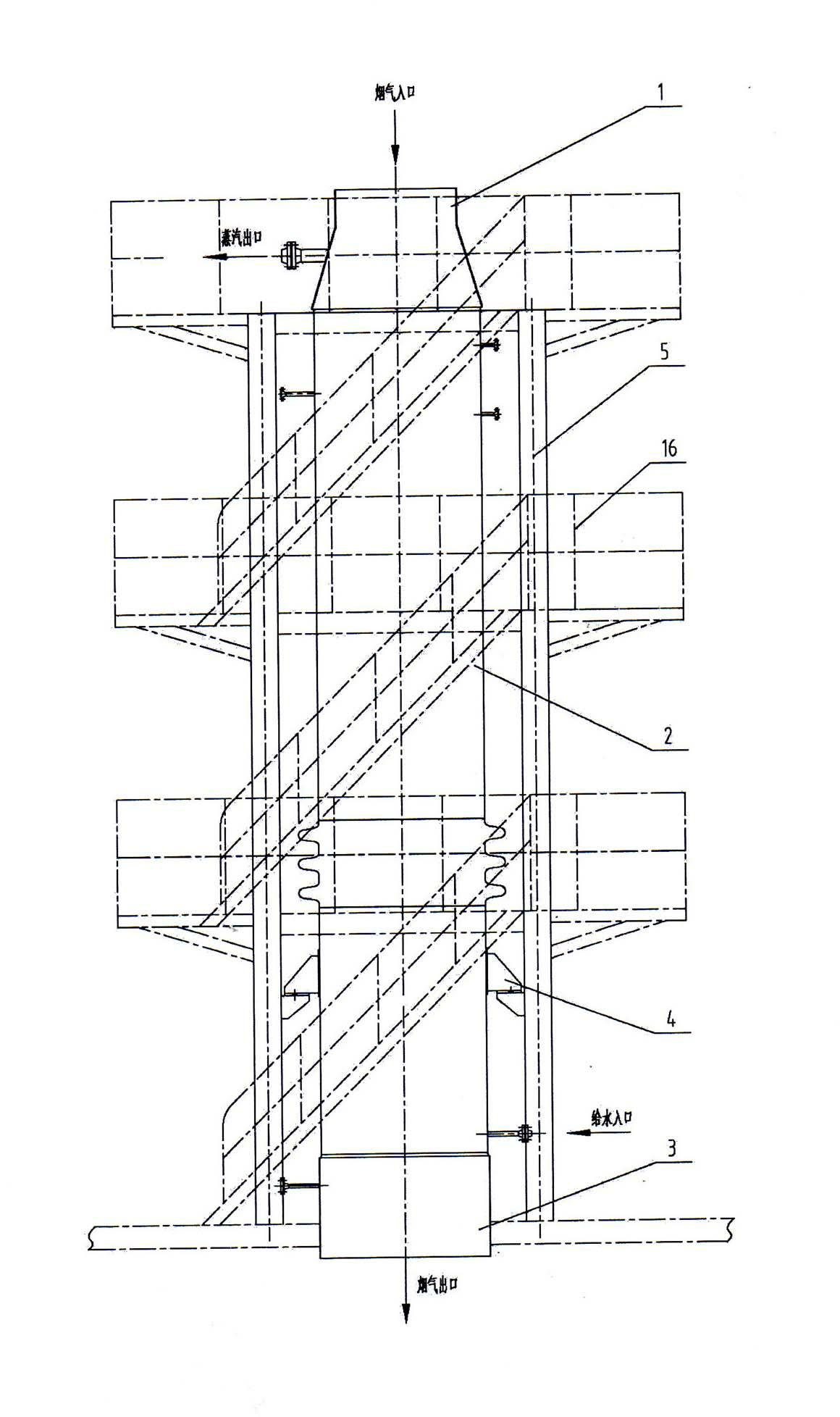

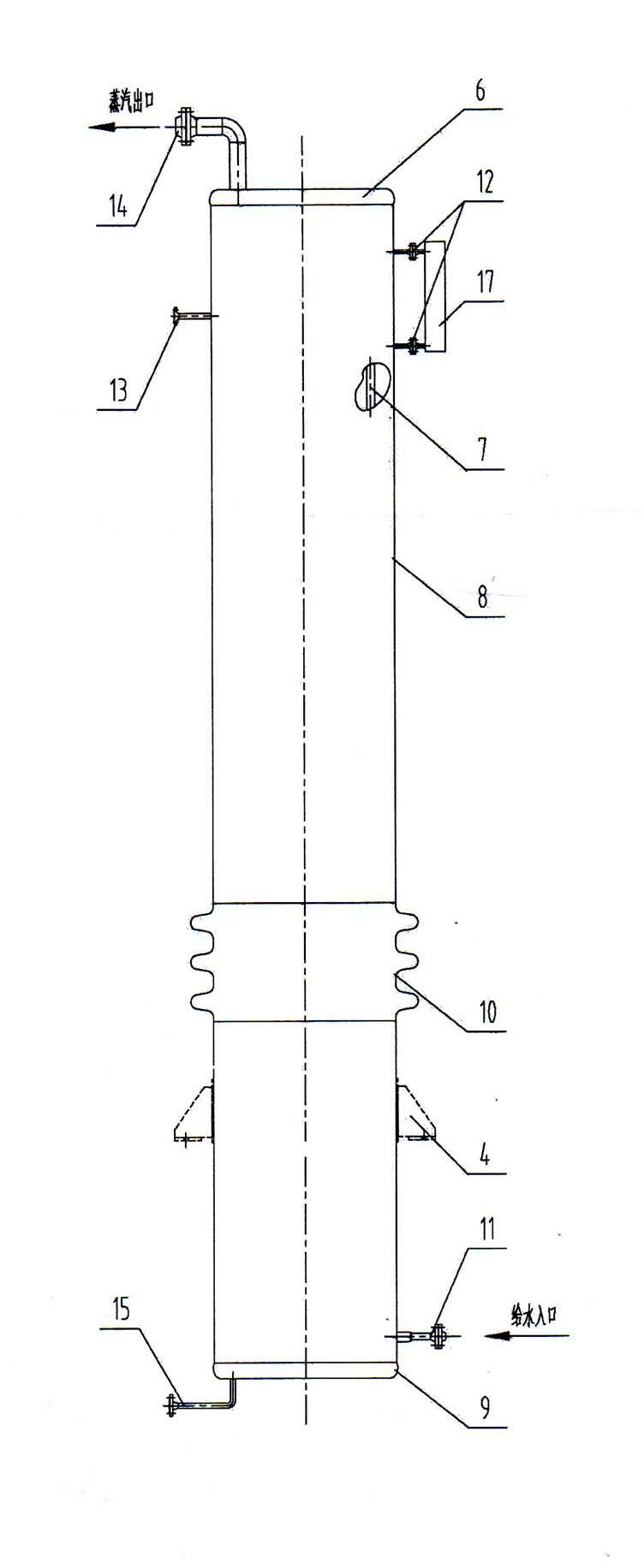

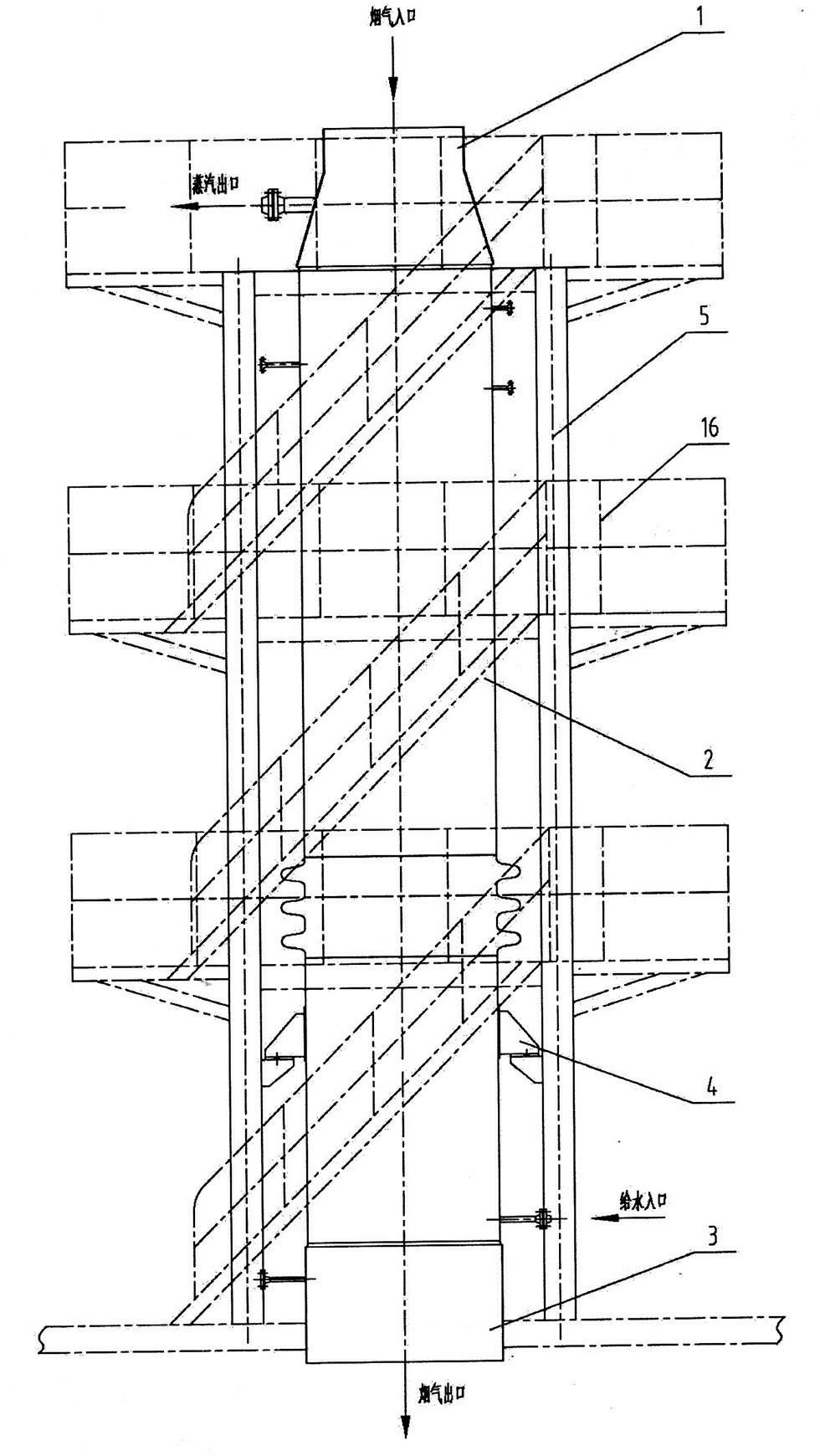

[0017] exist figure 1 and figure 2 In the schematic diagram of the vertical smoke tube waste heat boiler shown, the drum 2 is a vertical cylinder with an upper tube plate 6 at its upper end opening and a lower tube plate 9 at its lower end opening. Several vertical smoke tubes 7. The two ends are respectively fixed on the corresponding through holes of the upper tube plate 6 and the lower tube plate 7 to form a smoke tube bundle. A flue gas inlet smoke box 1 is provided at the upper end of the drum 2, and a smoke outlet smoke box 3 is provided at the lower end of the drum 2, and the three are connected together. The lower part of the outer wall of the above-mentioned drum 2 is provided with a feedwater inlet pipe 11 communicating with the cavity thereof, and the upper part of the upper tube plate 6 is provided with a steam outlet pipe 14 communicating with the cavity of the drum 2, which passes through the steam outlet of the flue gas inlet smoke box 1 Tube 14 may be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com