Combined body of composite type rotating sludge incineration kiln and reciprocating type sludge incineration kiln

A sludge incineration and composite technology, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as high mobility, sewage sludge, environmental pollution, etc., and achieve strong heat exchange capacity, good effect, and heat exchange. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

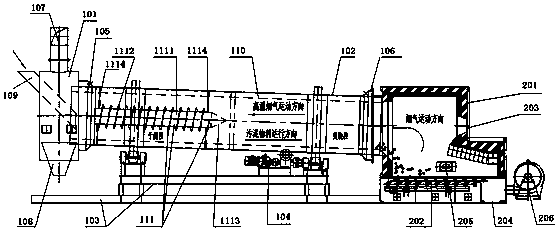

[0015] Such as figure 1 As shown, a combination of a composite rotary sludge incineration kiln and a reciprocating sludge incineration kiln. The composite rotary sludge incineration kiln includes an exhaust gas ash collection device 101, a cylinder 102, a support frame 103 for supporting the cylinder and A power device 104 that drives the cylinder to rotate. The front end of the cylinder is connected to the waste gas ash collection device through a soft sealing device 105. The top of the waste gas ash collection device has a waste gas discharge port 107, and the bottom of the waste gas ash collection device has an ash collection box 108. The waste gas There is a feed inlet 109 at the front end of the ash collecting device; a plurality of lifting plates 110 are arranged at intervals on the inner wall of the cylinder, which can lift the sludge material to the upper side of the cylinder according to the set angle, and the sludge material is discharged along the angle of the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com