Paper web double wire forming process

A double-wire forming and crafting technology, applied in the field of cardboard forming and paper web, can solve the problems of bubble bursting, reducing the retention force and the effect of paper quality, and achieve the effect of improving the tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

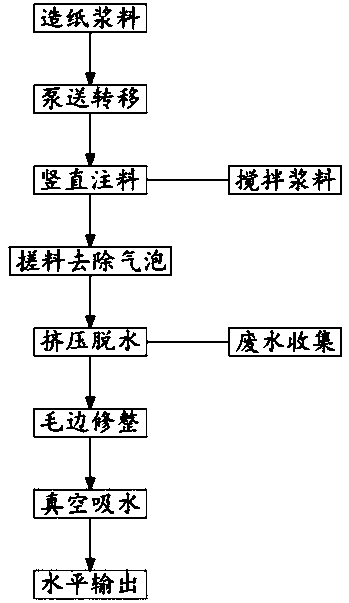

[0047] like figure 1 As shown, the double-web forming process of the paper web includes:

[0048]Step 1: Feeding process, the slurry in the slurry box 511 is pumped by the feeding pump 512 at the top of the slurry box 511 and transferred to the feeding box 521 located at the top of the first forming wire 2 and the second forming wire 3 through the feeding pipe 513. ;

[0049] Step 2: Material injection process, the slurry entering the material injection box 521 is output vertically downward through the screw discharge head 522, and the output slurry enters the first forming wire 2 and the second forming wire 3 vertically downward. In the airtight gap between, and transported down to the rubbing station located below the material injection box 521;

[0050] Step 3: rubbing process, the slurry that reaches the rubbing station is driven by the driving mechanism 612 to reciprocate the sliding plate 6110 and the second rubbing plate 6111 to rub the slurry. During the rubbing proc...

Embodiment 2

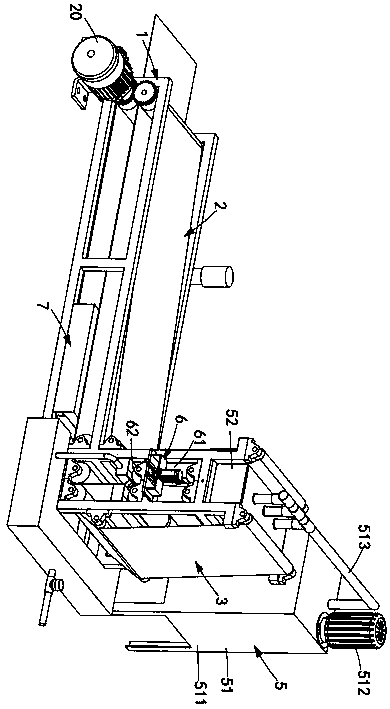

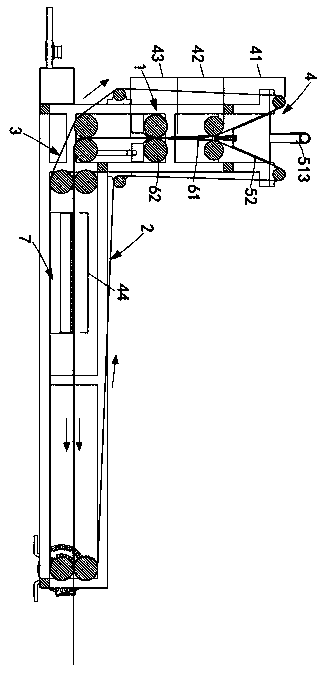

[0073] like figure 2 and image 3 As shown, a paper web twin-wire forming system includes:

[0074] A rack 1, the rack 1 is L-shaped and includes a first mounting portion 11 arranged vertically and a second mounting portion 12 arranged horizontally;

[0075] The first forming wire 2, the first forming wire 2 is arranged in a circular rotation along the frame 1 to form an endless wire ring;

[0076] The second forming wire 3, the second forming wire 3 is arranged in a circular rotation along the frame 1 to form an endless wire ring, which is correspondingly arranged with the first forming wire 2, and is arranged between the second forming wire 3 and the first forming wire 2. A forming zone 4 is formed between the forming wires 2;

[0077] The feeding device 5 includes a feeding mechanism 51 and a feeding mechanism 52 communicating with the feeding mechanism 51. The feeding mechanism 51 is arranged on one side of the first installation portion 11, and the feeding mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com