An intelligent punching device

A drilling device and intelligent technology, applied in medical science, surgery, etc., can solve the problems of inability to remove the skull, low drilling efficiency, time-consuming and laborious, etc., to avoid the influence of human factors, simple structure and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

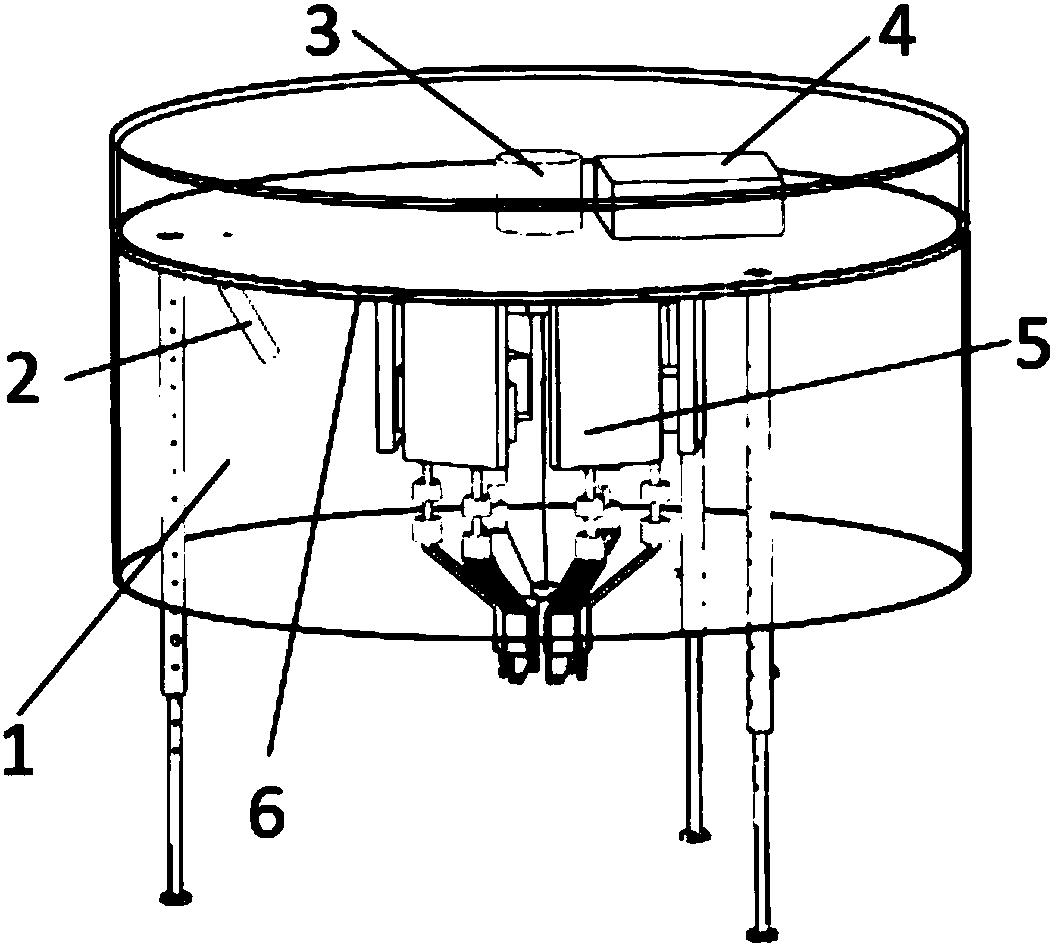

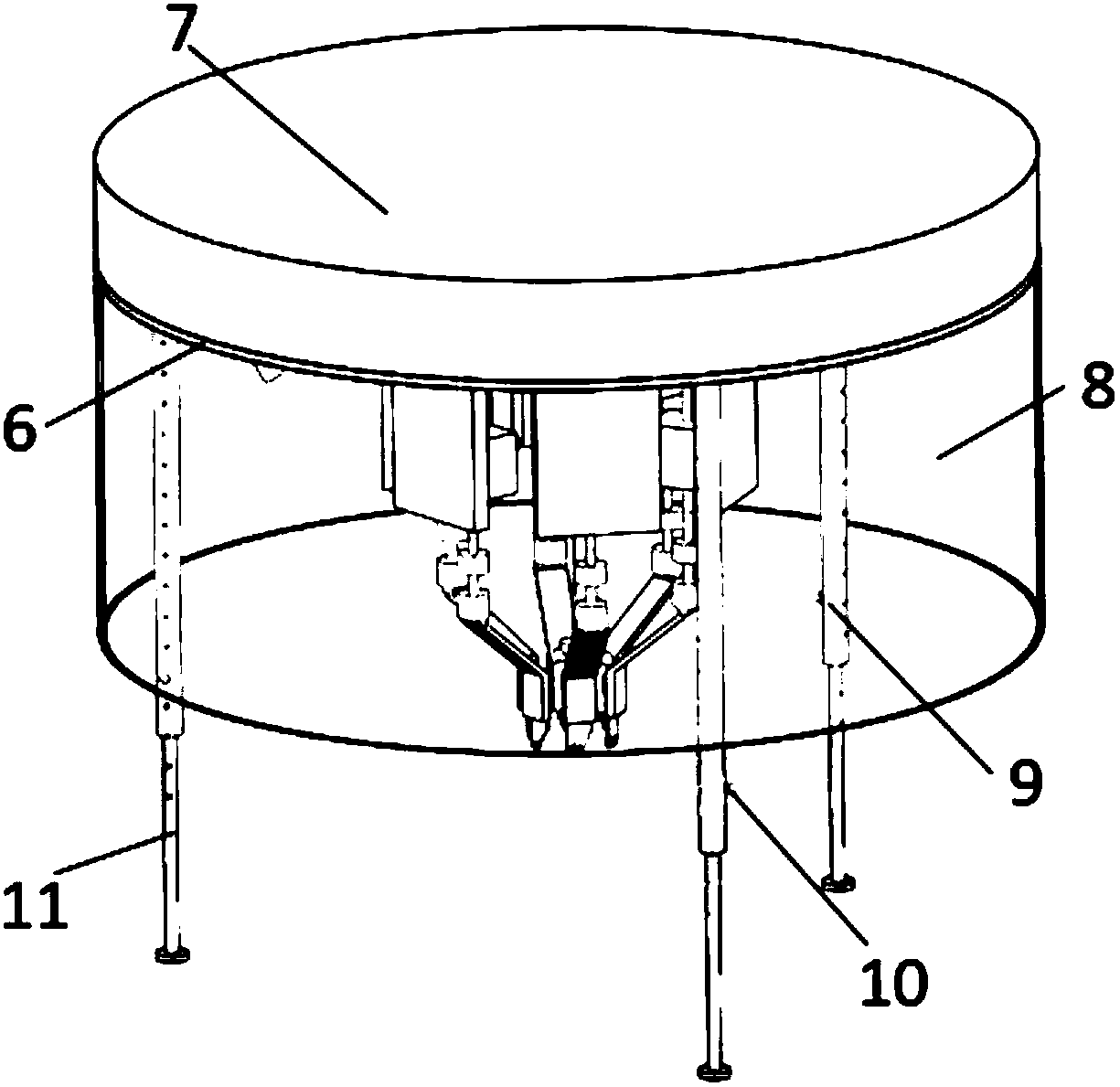

[0075] It is an example to make the hole of 8mm in diameter on the rabbit calvaria, to illustrate the working process of the device of the present invention:

[0076] 1. Take a rabbit weighing between 2.5 and 3.5kg, inject a certain dose of general anesthesia reagent into the rabbit's ear vein to perform general anesthesia on the rabbit, and then shave the rabbit's calvaria. On the operating table, tie up its four legs, sterilize the shaved area with povidone iodine, and then spread a drapery and incise the skin with surgical instruments to expose the position of the calvaria to be punched;

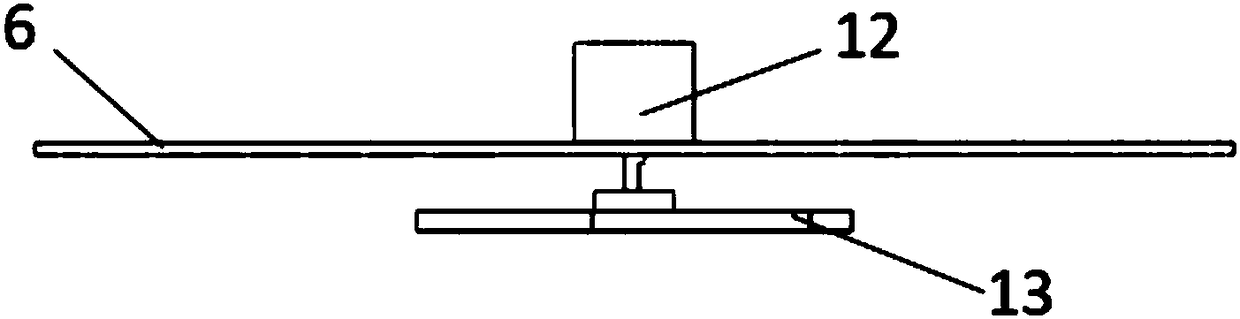

[0077] Two, select the blade and blade base for punching 8mm diameter holes, install the blade and blade base that have been sterilized in advance on the punching device of the present invention, then put the device on the operating table, and adjust the position of the device , so that the blade is located directly above the hole to be punched, by pulling out the positioning pin on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com