Water purifier system with flush valve

A flushing valve and pure water machine technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high failure rate, high cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

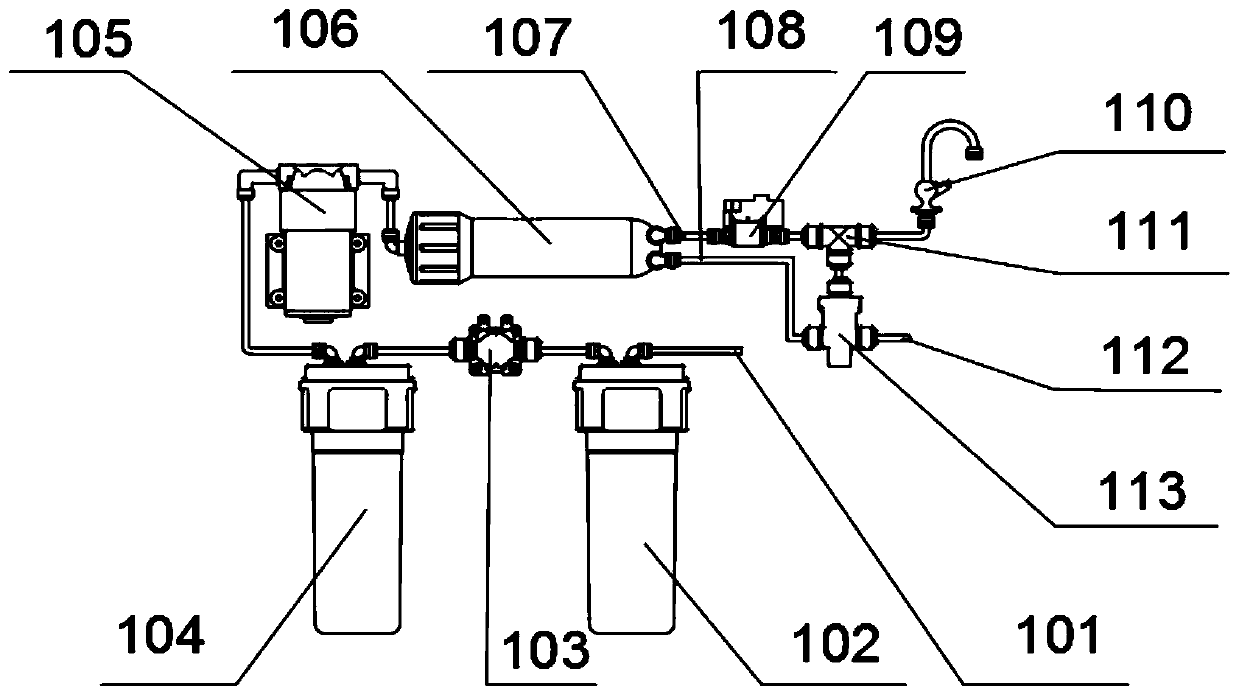

[0031] Such as figure 1 As shown, the present invention connects the concentrated water inlet 1 of the flushing valve 113 on the concentrated water pipe 108 of the large flux reverse osmosis filter group 106, the drain port 11 of the flushing valve 113 is connected to the concentrated water discharge pipe 112, and the flushing valve 113 The upper end communicates with the vertical opening of the tee 111 on the clean water pipe 107, the tee 111 is located between the high pressure switch 109 and the clean water faucet 110, and the two horizontal openings are respectively the high pressure switch 109 and the clean water faucet 110 When the pure water mechanism is used, the flushing valve 113 is in a conduction state with a small flow rate, the high-pressure switch 109, the water shut-off valve 103 and the booster pump 105 are activated, and the raw water enters from the raw water pipe 101 and passes through the first filter group 102, the second The second filter group 104 pre-f...

Embodiment 2

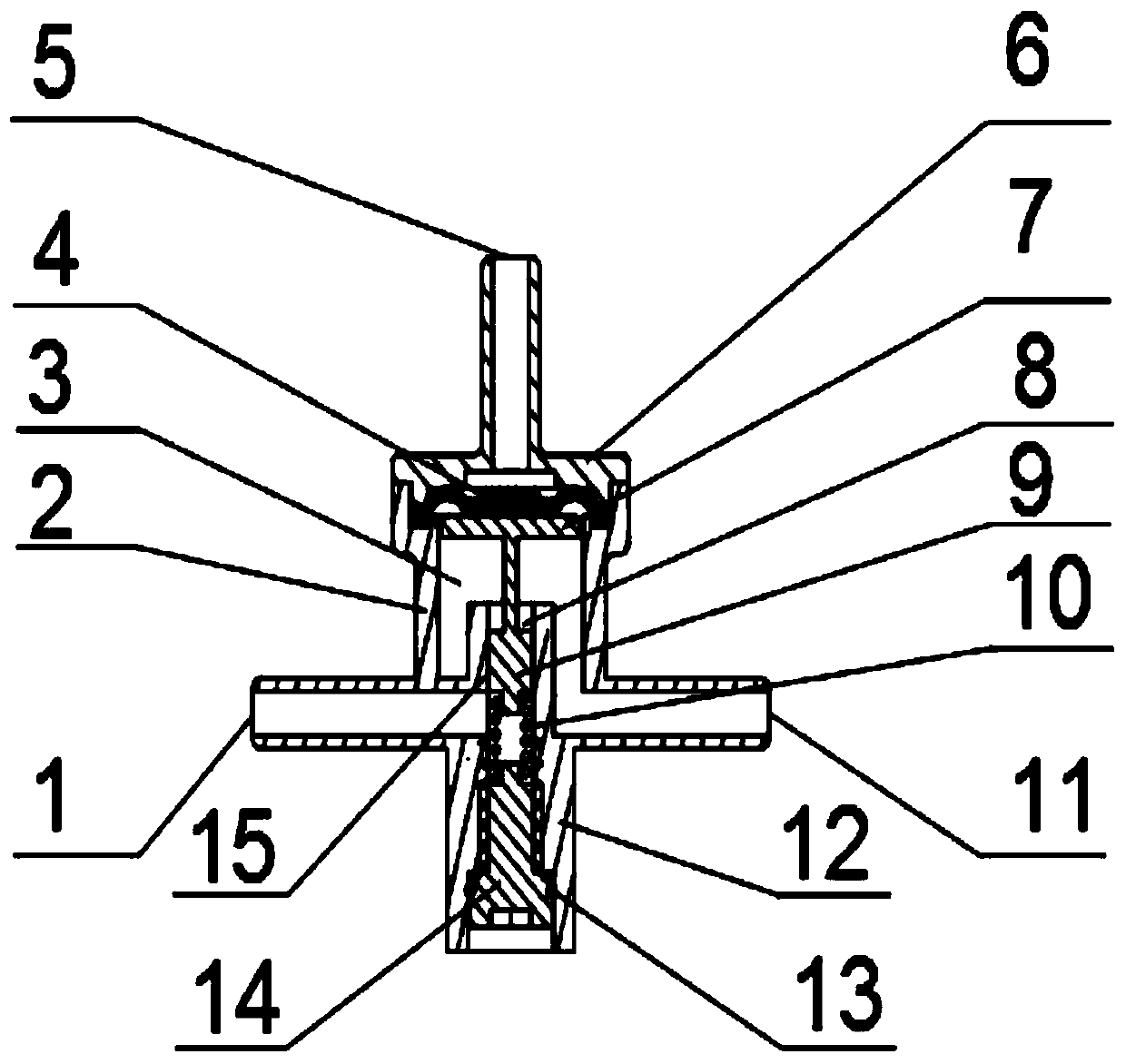

[0033] In this example, if figure 2 As shown, the flushing valve 113 also includes a valve body 2, the upper end of the valve body 2 is provided with a matching bonnet 6, and the clean water inlet 5 on the bonnet 6 communicates with the clean water pipe 107. During the pure water machine water process, the clean water Continuously flow out from the water purification faucet 110. At this time, the water pressure in the water purification pipe 107 is relatively small, and the flow blocking assembly hinders the concentrated water from the concentrated water inlet 1 into the drain chamber 3. The concentrated water in the valve body 2 passes through the first resistance. The flow channel 15 slowly enters the drain cavity 3 in a small amount, and then is discharged to the outside of the valve body 2 through the connected drain port 11 . When the water machine is stopped, the high-pressure switch 109 is closed, and the delay circuit starts. At this time, the booster pump 105 and the...

Embodiment 3

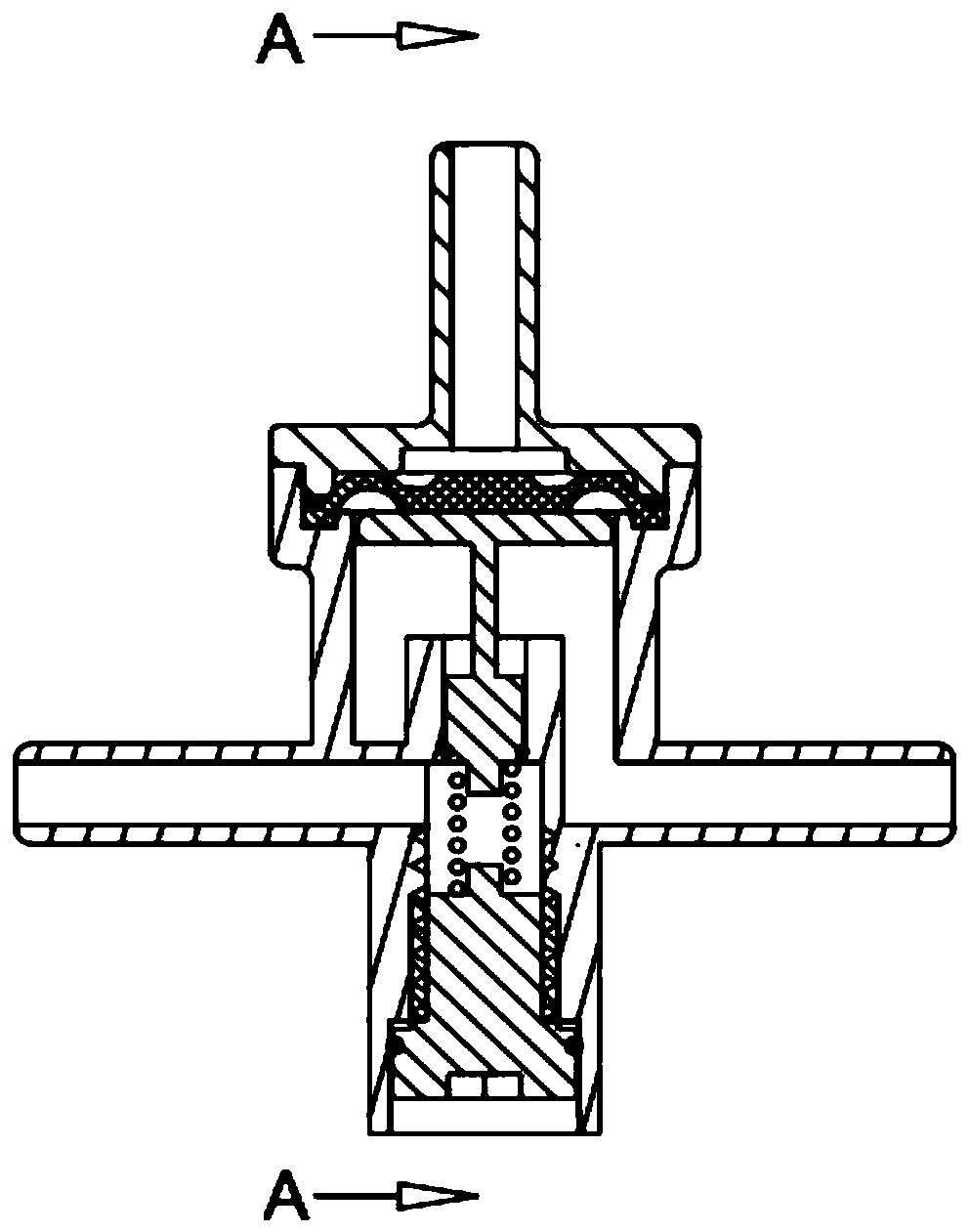

[0035] In this example, if image 3 with Figure 4 As shown, the valve body 2 is provided with a third blocking channel 18 for the concentrated water to enter the drain chamber 3. The valve body 2 has a sealing water port with a structure of the valve body 2 inside the valve body 2, and the sealing water port is located on the third blocking channel 18. During the water production process, the pressure at the clean water inlet 5 is small, so that the concentrated water stays in the concentrated water channel 24 until the water pressure rises and pushes the second diaphragm 23; at this time, the concentrated water passes through the third blocking channel 18 A small amount enters the drain chamber 3; under the fixing action of the outer cover 21, the second spring 20 exerts elastic force on the pressure plate 22 in the opposite direction, so that the second diaphragm 23 can return to block the concentrated water channel 24 and the third blocking channel 18, effectively maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com