Automatic assembling machine for lithium battery production

A technology for automatic battery packs and lithium batteries, which is used in battery assembly machines, secondary battery manufacturing, non-aqueous electrolyte batteries, etc., and can solve problems such as battery position offset and slippage, battery and pole piece pressing cannot be aligned, and battery pressing fails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

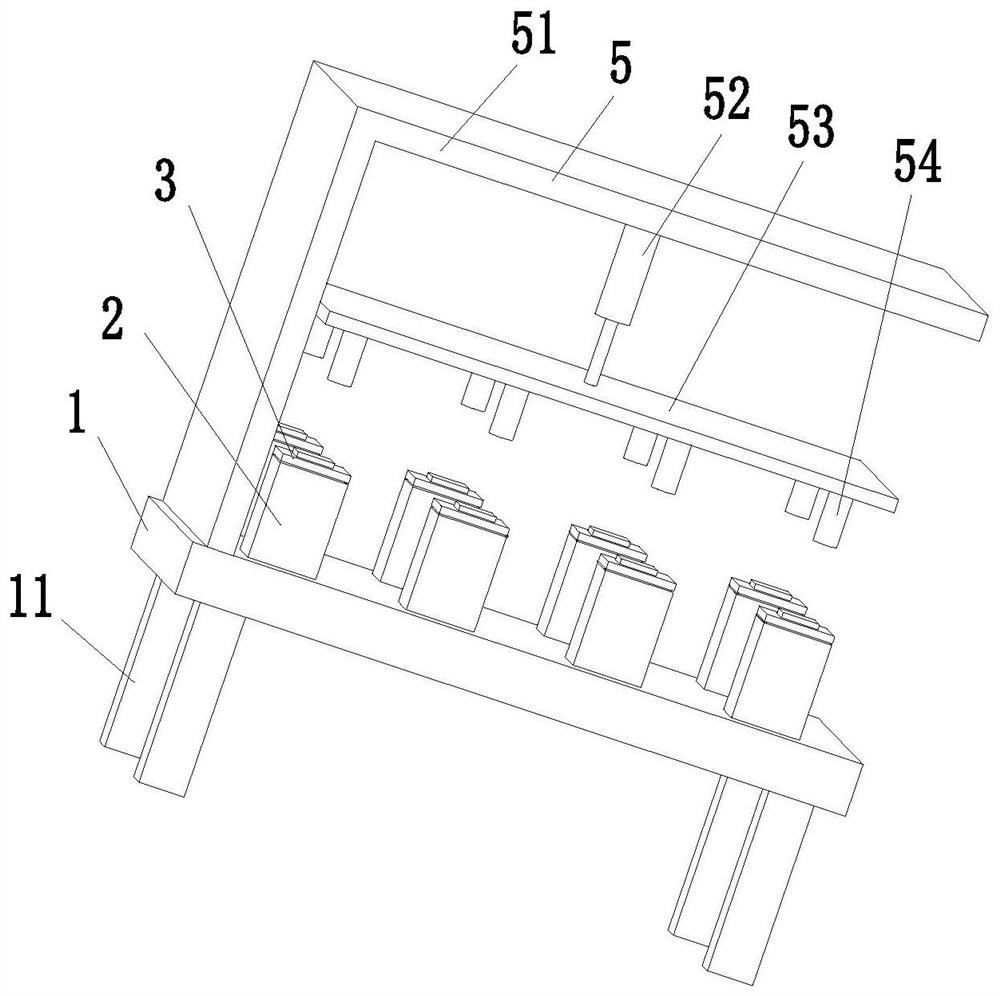

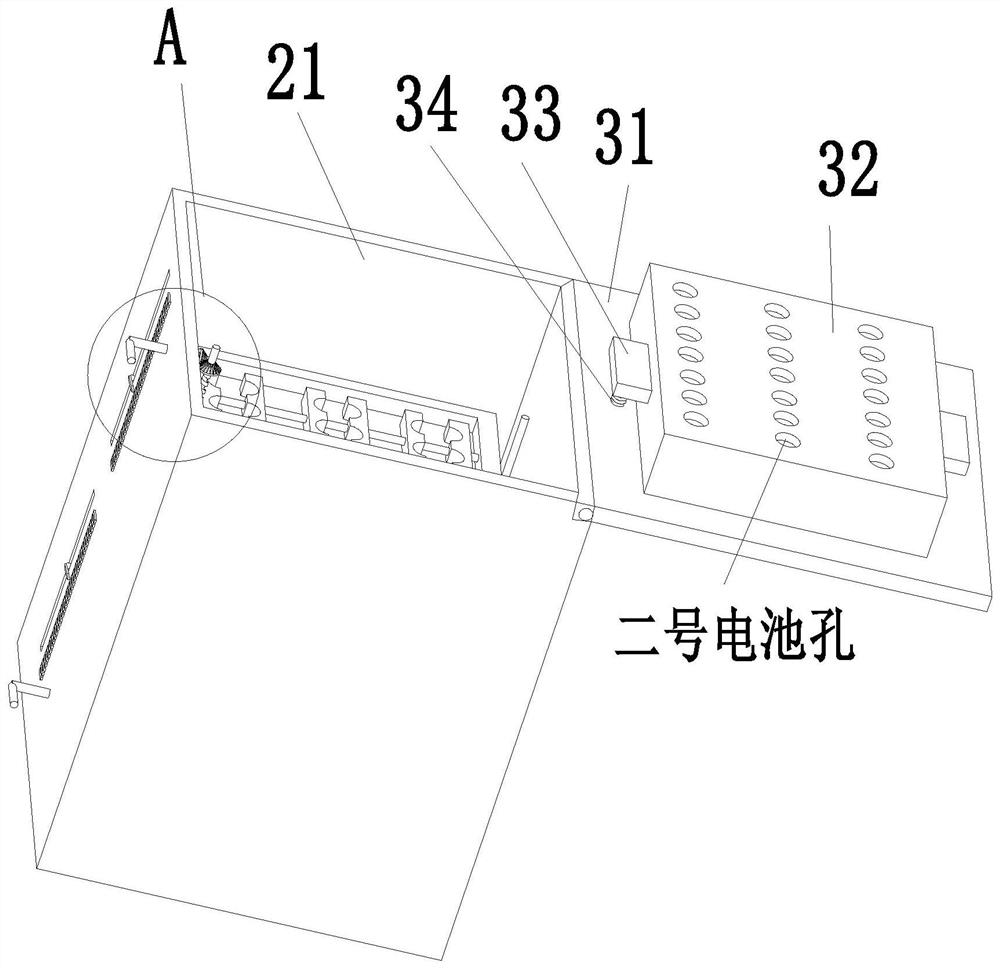

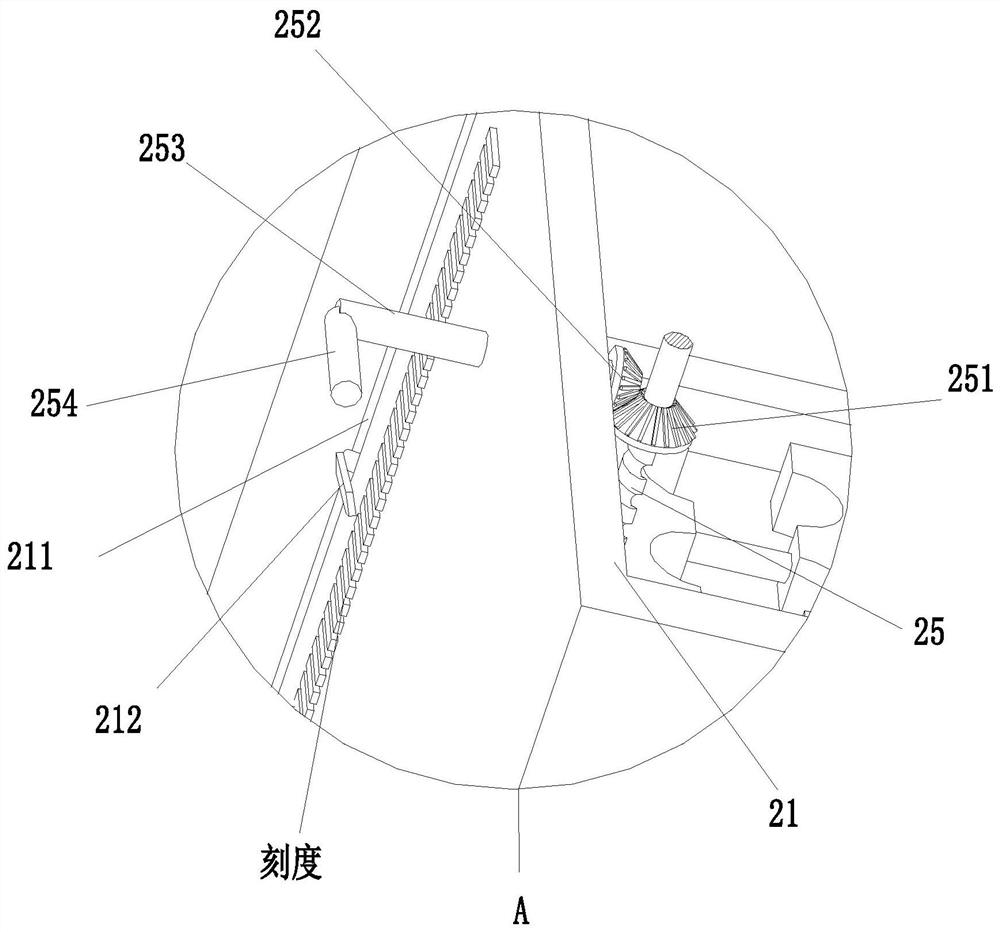

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0033]An automatic assembly machine for lithium battery production, comprising a workbench 1, a tablet press box 2, an installation cover 3 and a pressing device 5, with tripods 11 installed at the four corners below the workbench 1, and a plurality of groups installed above the workbench 1 Tablet pressing box 2, a pressing device 5 is installed above the pressing box 2, and an installation cover 3 is hinged on the upper end of the tablet pressing box 2. In addition, an installation sleeve 4 is also included, wherein;

[0034] The tablet pressing box 2 includes an installation box 21, a locking mechanism 22, a limit post 23, a connecting block 24, a No. 2 screw 25, a No. 1 screw 26, a return frame 27 and a fixing mechanism 28. The installation box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com