Blade head overhanging type runner

A blade and runner technology, applied in the field of blade head cantilever runners, can solve problems such as the inability to effectively improve the internal flow state of the cavity, and the inability to significantly reduce the adverse effects of the S-characteristic pressure pulsation of the pump turbine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

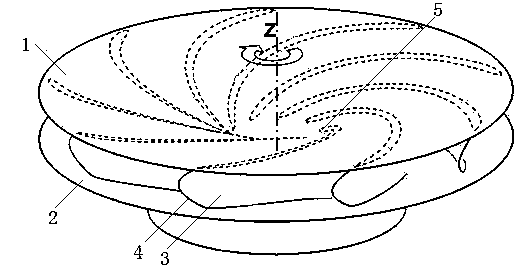

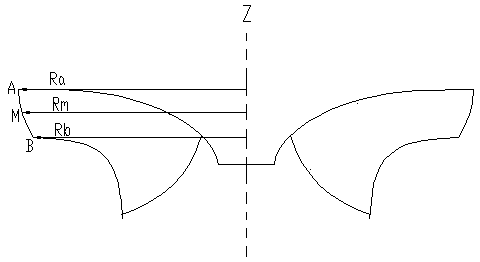

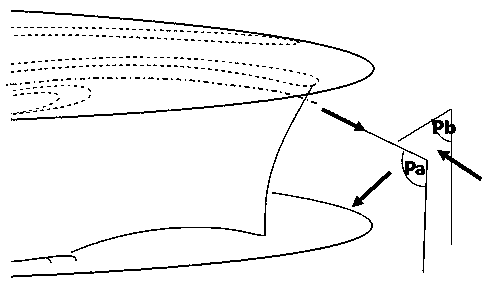

[0031] see Figure 1-Figure 5, a blade head cantilever type runner, comprising an upper crown 1, a lower ring 2 and a plurality of blades 3, the upper crown 1 and the lower ring 2 are rotationally symmetrical about the rotation axis of the runner, and the blades 3 include a water inlet edge 4 and the water outlet edge 5, the blade 3 is located between the upper crown 1 and the lower ring 2, the blade 3 is connected with the upper crown 1 and the lower ring 2 respectively, and the intersecting line formed by the connection between the blade 3 and the upper crown 1 is the blade upper crown shape line , the intersecting line formed by the connection between the blade 3 and the lower ring is the lower ring profile line of the blade, the intersection point of the water inlet edge 4 and the upper crown 1 is A, the intersection point of the water inlet edge 4 and the lower ring 2 is B, and the water outlet The intersection point between the side 5 and the upper crown 1 is C, the inte...

Embodiment 2

[0038] see Figure 1-Figure 5 , a blade head cantilever type runner, comprising an upper crown 1, a lower ring 2 and a plurality of blades 3, the upper crown 1 and the lower ring 2 are rotationally symmetrical about the rotation axis of the runner, and the blades 3 include a water inlet edge 4 and the water outlet edge 5, the blade 3 is located between the upper crown 1 and the lower ring 2, the blade 3 is connected with the upper crown 1 and the lower ring 2 respectively, and the intersecting line formed by the connection between the blade 3 and the upper crown 1 is the blade upper crown shape line , the intersecting line formed by the connection between the blade 3 and the lower ring is the lower ring profile line of the blade, the intersection point of the water inlet edge 4 and the upper crown 1 is A, the intersection point of the water inlet edge 4 and the lower ring 2 is B, and the water outlet The intersection point between the side 5 and the upper crown 1 is C, the int...

Embodiment 3

[0043] see Figure 1-Figure 5 , a blade head cantilever type runner, comprising an upper crown 1, a lower ring 2 and a plurality of blades 3, the upper crown 1 and the lower ring 2 are rotationally symmetrical about the rotation axis of the runner, and the blades 3 include a water inlet edge 4 and the water outlet edge 5, the blade 3 is located between the upper crown 1 and the lower ring 2, the blade 3 is connected with the upper crown 1 and the lower ring 2 respectively, and the intersecting line formed by the connection between the blade 3 and the upper crown 1 is the blade upper crown shape line , the intersecting line formed by the connection between the blade 3 and the lower ring is the lower ring profile line of the blade, the intersection point of the water inlet edge 4 and the upper crown 1 is A, the intersection point of the water inlet edge 4 and the lower ring 2 is B, and the water outlet The intersection point between the side 5 and the upper crown 1 is C, the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com