Dilution water addition device and method for adjusting cross-direction paper basis weight

A technology of quantitative and adding devices for banners, which is applied in the direction of papermaking, paper machine, paper machine wet end, etc. It can solve the problems of affecting fiber orientation, making manufacturing difficult, increasing the manufacturing difficulty and processing cost of dilution and water release devices, and avoiding cross flow , Guarantee the performance of slurry distribution and the effect of diluting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

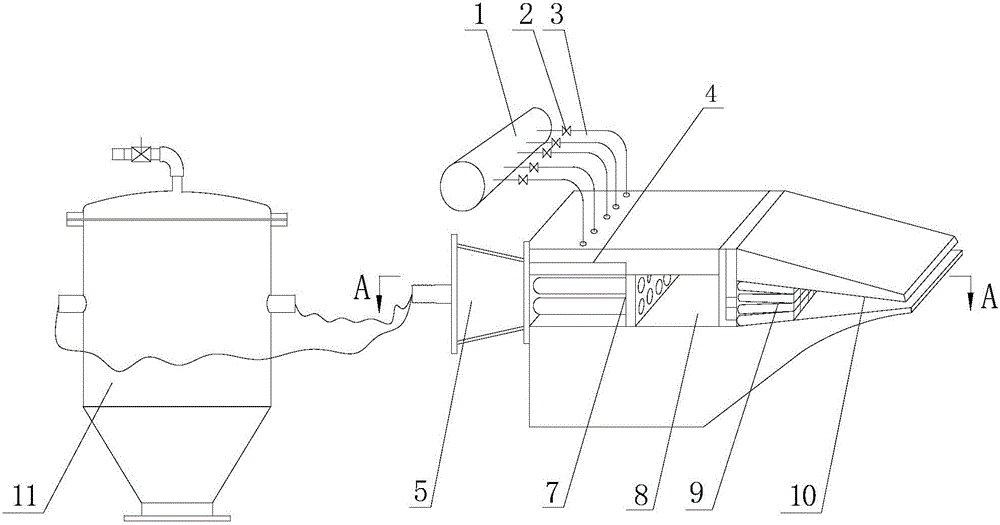

[0038] In this embodiment, a kind of dilution water adding device for adjusting paper banner quantitatively is used, and the used headbox is as figure 1 As shown, it is composed of a slurry distribution main pipe, a slurry distribution tube bundle, a steady flow chamber, a turbulence generator and a lip area, and a centralized slurry distribution device is also connected to the inlet end of the headbox.

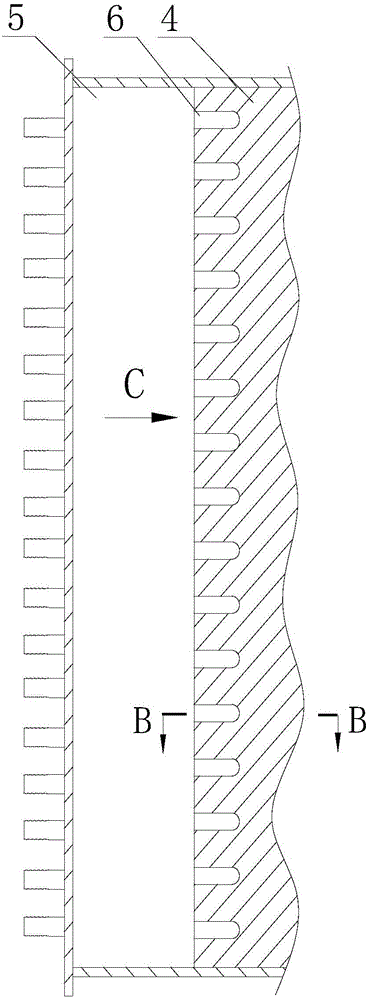

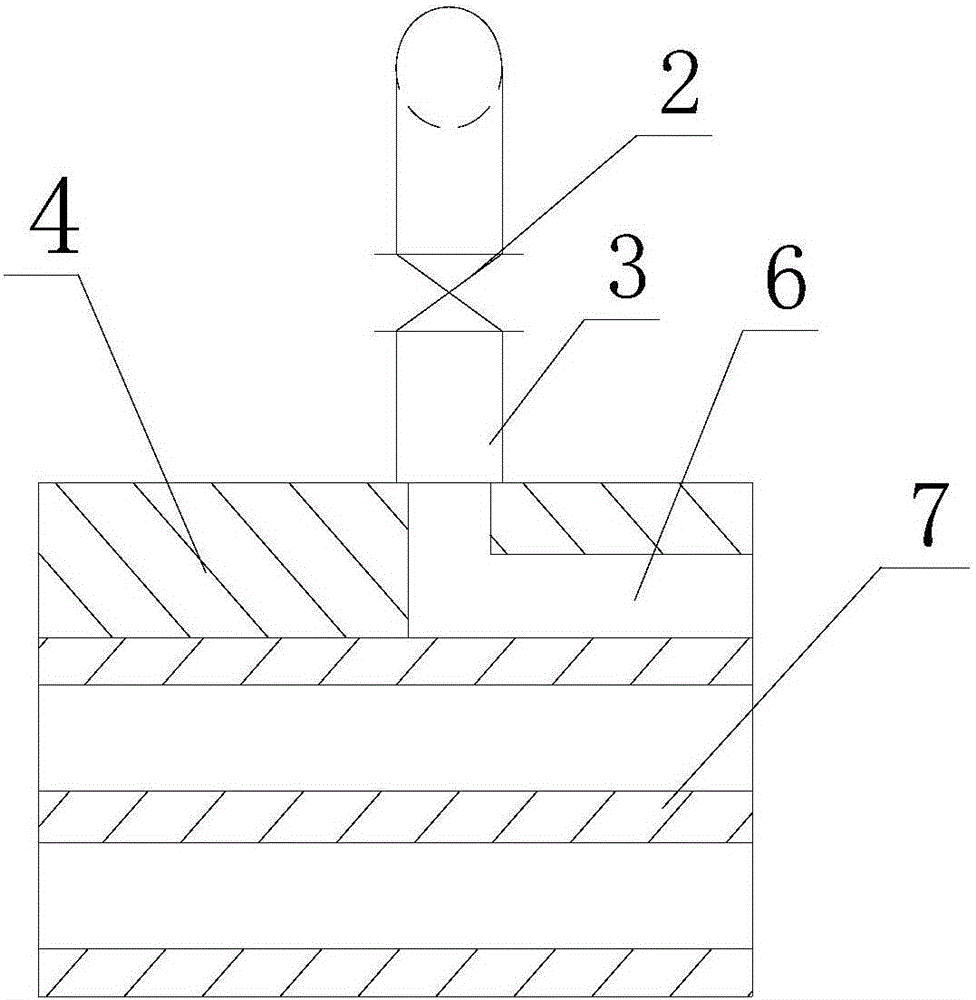

[0039] Dilution water addition device such as Figure 1-7 As shown, it includes a dilution water main pipe, a dilution water regulating valve, a dilution water branch pipe, a concentration adjustment module, a dilution water control system (not shown in the figure) and a slurry distribution main pipe. The slurry distribution main pipe is not only a part of the dilution water adding device, but also a component of the headbox. The dilution water from the dilution water main pipe passes through the dilution water regulating valve to adjust the flow rate, and then enters the co...

Embodiment 2

[0050] A kind of dilution water adding device that the present embodiment adjusts the quantitative use of paper banner, compared with embodiment 1, its difference is:

[0051] Such as Figure 8 or Figure 9 As shown, the device is equipped with two sets of dilution water adding components, and at the same time, concentration adjustment modules are installed above and below the slurry distribution branch pipe, and the number of rows of the slurry distribution branch pipe is relatively large (such as Figure 4~6 row, shown as 3 rows in the figure), there are two sets of dilution water adding components, and the dilution water above and below the slurry distribution branch pipe enters the slurry distribution main pipe, and then turns 180° to enter the slurry distribution after mixing with the slurry In branch pipe 7, this increases the uniformity of slurry concentration in each distribution slurry branch pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com