Inclined plate settling separating device

A separation device and inclined plate precipitation technology, applied in separation methods, feeding/discharging devices of sedimentation tanks, separation of dispersed particles, etc., can solve problems such as dust enrichment, and achieve simple shape, reasonable flow field distribution and flow rate. , the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

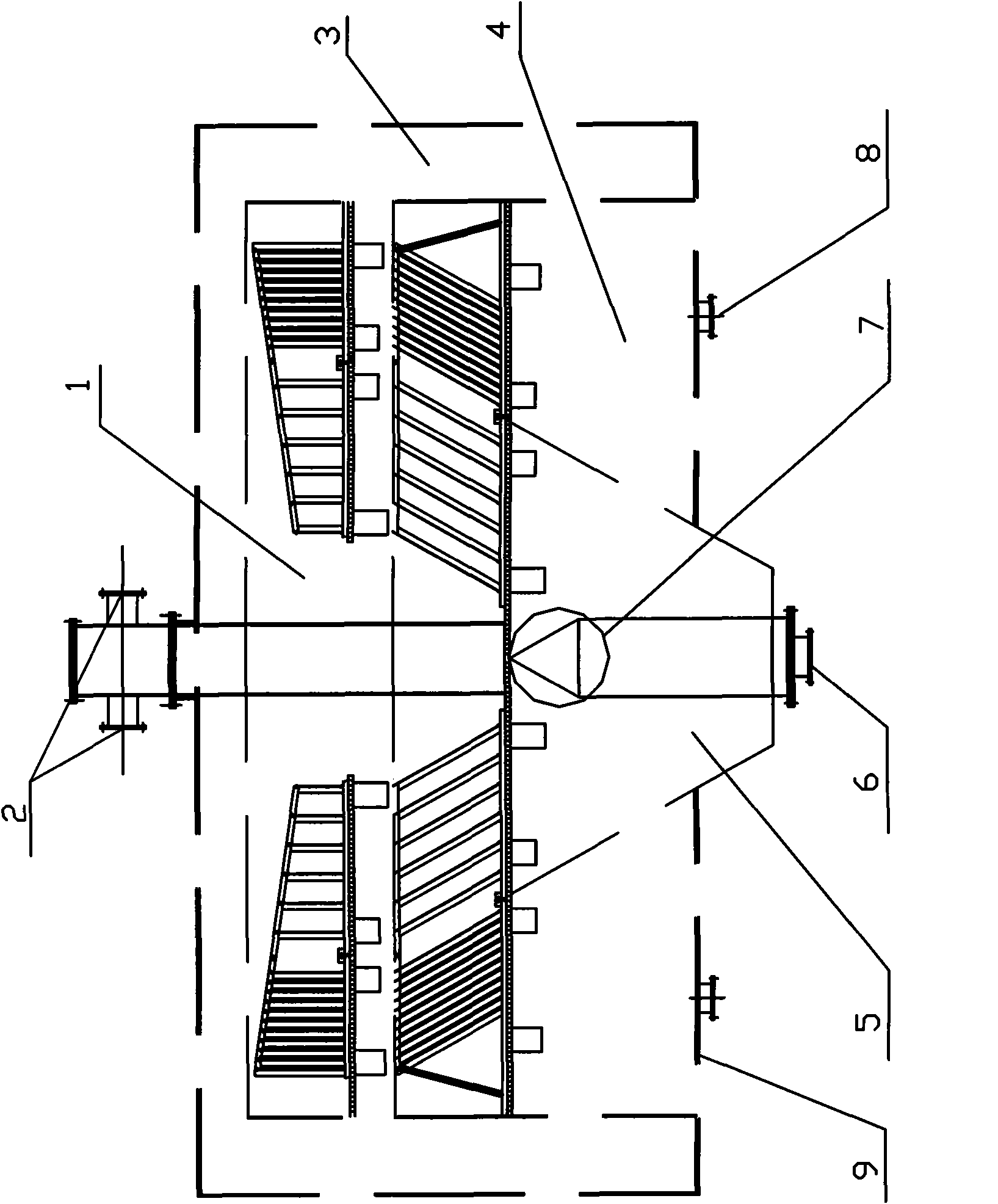

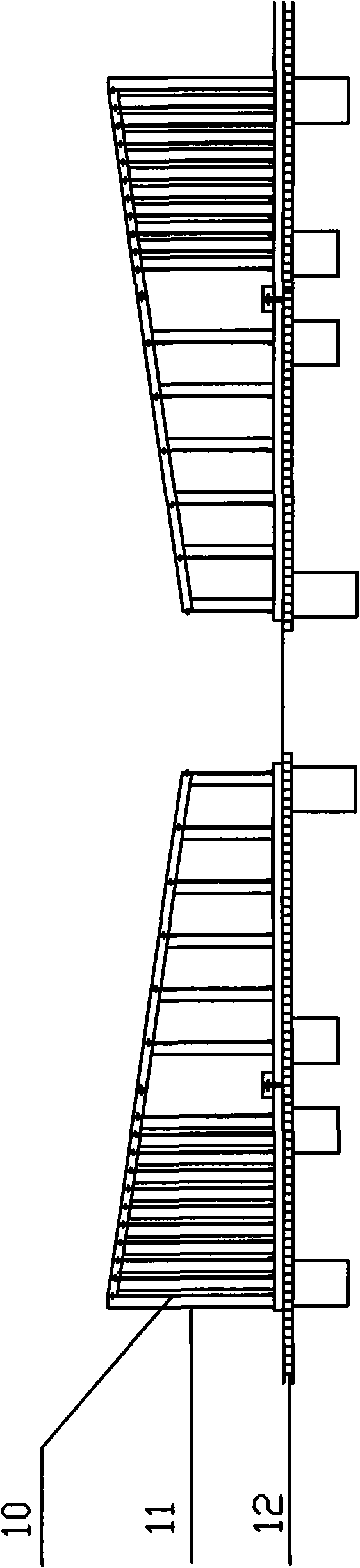

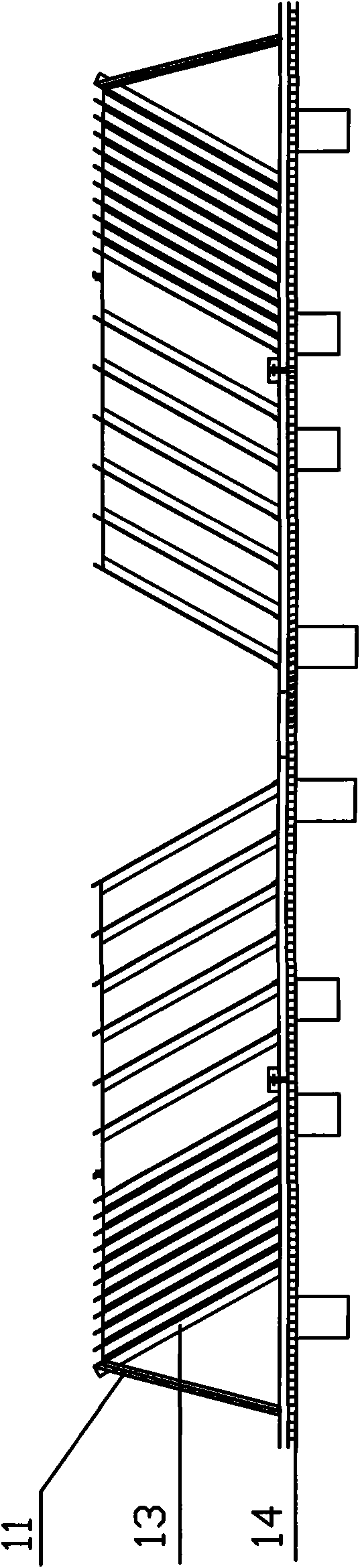

[0019] The technical scheme and specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] like Figure 1-Figure 3 As shown, a kind of inclined plate sedimentation separation device that the present invention relates to includes a tower body 9, an ammonium sulfate slurry inlet 2 entrained with soot, an ash accumulation area 4, a finished product area 5, a finished product outlet area 6, and an ash accumulation discharge port 8, The tower body 9 is made of steel or concrete, and the middle top of the tower body 9 is provided with an ammonium sulfate slurry inlet 2 entrained with soot. The finished product area 5 is arranged in the tower body 9 above the middle of the bottom of the tower body 9, and the finished product outlet Area 5 is set on the bottom of the tower body 9 below the finished product area 4, and around the finished product area 5 inside the tower body 9 is the ash accumulation area 4, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com