Method for detecting content of benzene series in lithographic printing materials based on ionic liquid

A technology of ionic liquid and benzene series, which is applied in the field of chemical analysis and detection materials, can solve problems such as instability and inaccurate detection results of benzene series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

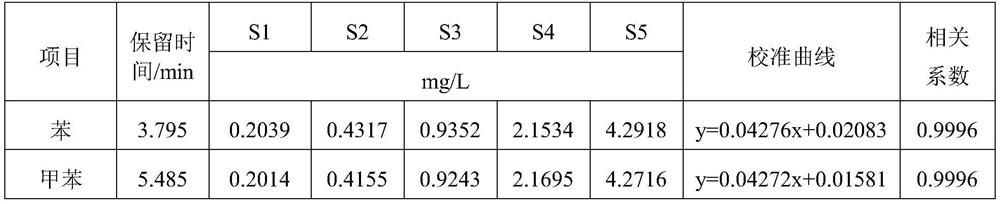

[0047] In this example, the method for detecting benzene series hazards in lithographic printed matter is detected by GC-MS method, and the detection data is analyzed by external standard method.

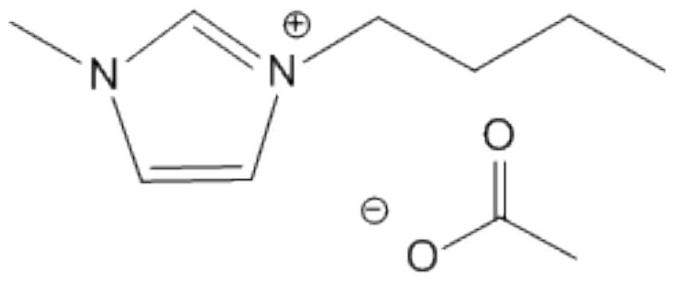

[0048] The method for detecting benzene series hazards in lithographic printed matter in this embodiment uses 1-butyl-3-methylimidazolium acetate ionic liquid as a solvent for the dispersion pretreatment of the sample, because 1-butyl-3-methyl Imidazolium acetate ionic liquid is easy to absorb water. Before using the ionic liquid that has been placed for a long time after opening, it is necessary to evaporate the ionic liquid at 80°C with a vacuum of 0.1MPa for 8 hours to ensure that all residual organic solvents are removed; if necessary , add alcohol to the ionic liquid, and carry out vacuum distillation after mixing until there is no distilled liquid. This method utilizes the strong hydrogen bond and mutual solubility between methanol and water, thereby destroying the Interaction...

Embodiment 2

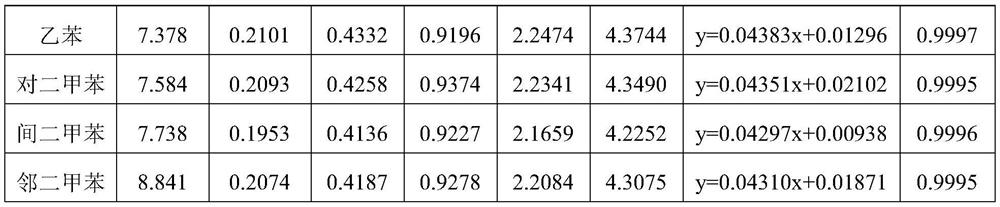

[0077] Embodiment 2 precision and accuracy experiment

[0078] Use a paper cutter to cut the base paper of selected lithographic samples into six pieces of paper with an area of 0.5cm×0.5cm according to the above method, put them into six headspace bottles respectively, and add 1ml to each bottle with a concentration of 1mg / L standard sample, capped immediately.

[0079] The detection and analysis method in the above-mentioned embodiment 1 was used for parallel determination 6 times, and the repeatability detection results are shown in Table 2 below.

[0080] Table 2 Repeatability test results

[0081]

[0082] The data in Table 2 above shows that the relative standard deviations of the peak areas of the various benzene series components involved in the present invention are all less than 4%, which shows that the detection precision of this method is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com