Horizontal pulverized coal boiler with single furnace pipe

A pulverized coal boiler and furnace furnace technology is applied in the directions of using multiple fuel combustion, block/powder supply/distribution, using block fuel and powder fuel combustion, etc., and can solve problems such as inconvenient operation of furnace furnace, etc. Achieve high position accuracy, improve efficiency, and ease of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiments shown below are intended as a description of various configurations of the disclosed subject technology, and are not intended to represent the only configurations in which the disclosed subject technology may be practiced. The specific embodiments include specific details to provide a thorough understanding of the technology of the disclosed subject matter. It will be clear and obvious, however, to those skilled in the art that the disclosed subject technology is not limited to the specific details shown herein and can be practiced without these specific details.

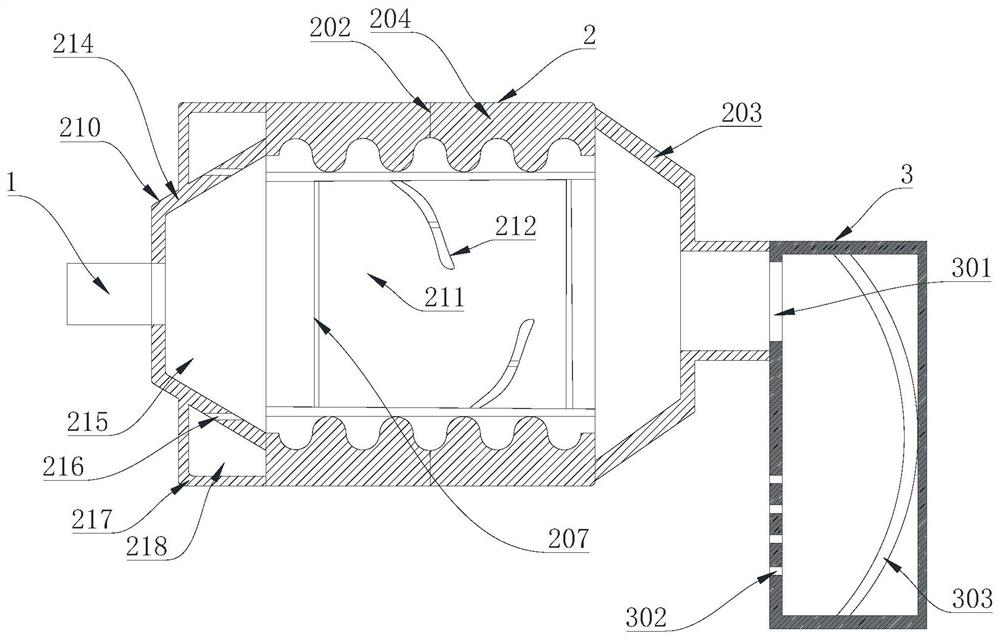

[0039] Generally, the operating principle of a pulverized coal boiler is that the pulverized coal and the primary air burner 1 are sprayed into the furnace body 202, and the tertiary air or return air enters the furnace body 202 according to a certain proportion. The fuel has a higher combustion efficiency, thereby improving the efficiency of the boiler. The high-temperature flue gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com