Large air-cooling steam turbo generator stator capable of improving aeration-cooling effect

A steam turbine generator, ventilation and cooling technology, applied in the direction of magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of increasing the copper loss of the wire rod, exceeding the allowable temperature rise, and the coil temperature rising, etc. Improve heat dissipation efficiency, increase heat load and power density, and uniformize the overall temperature area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

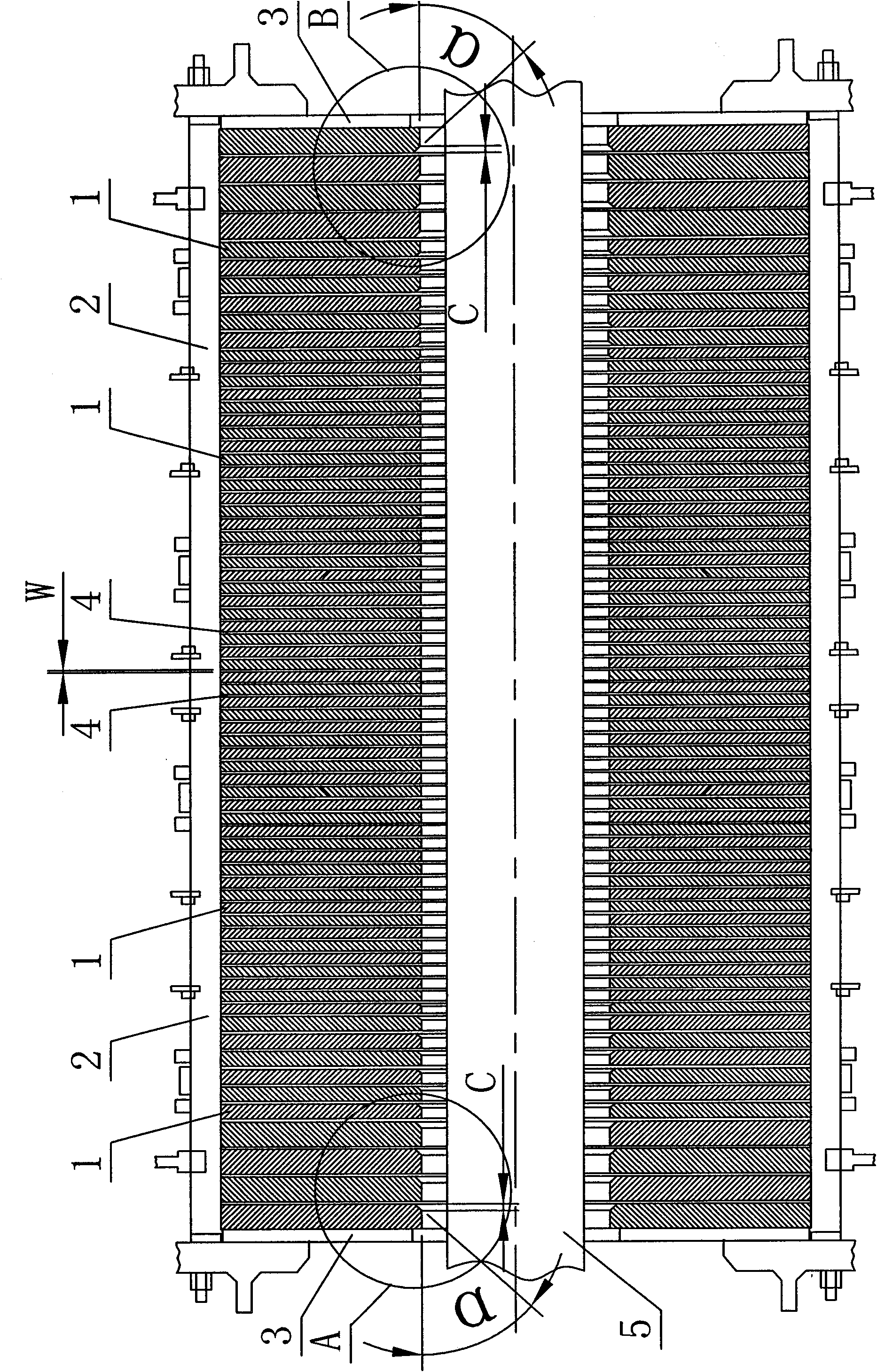

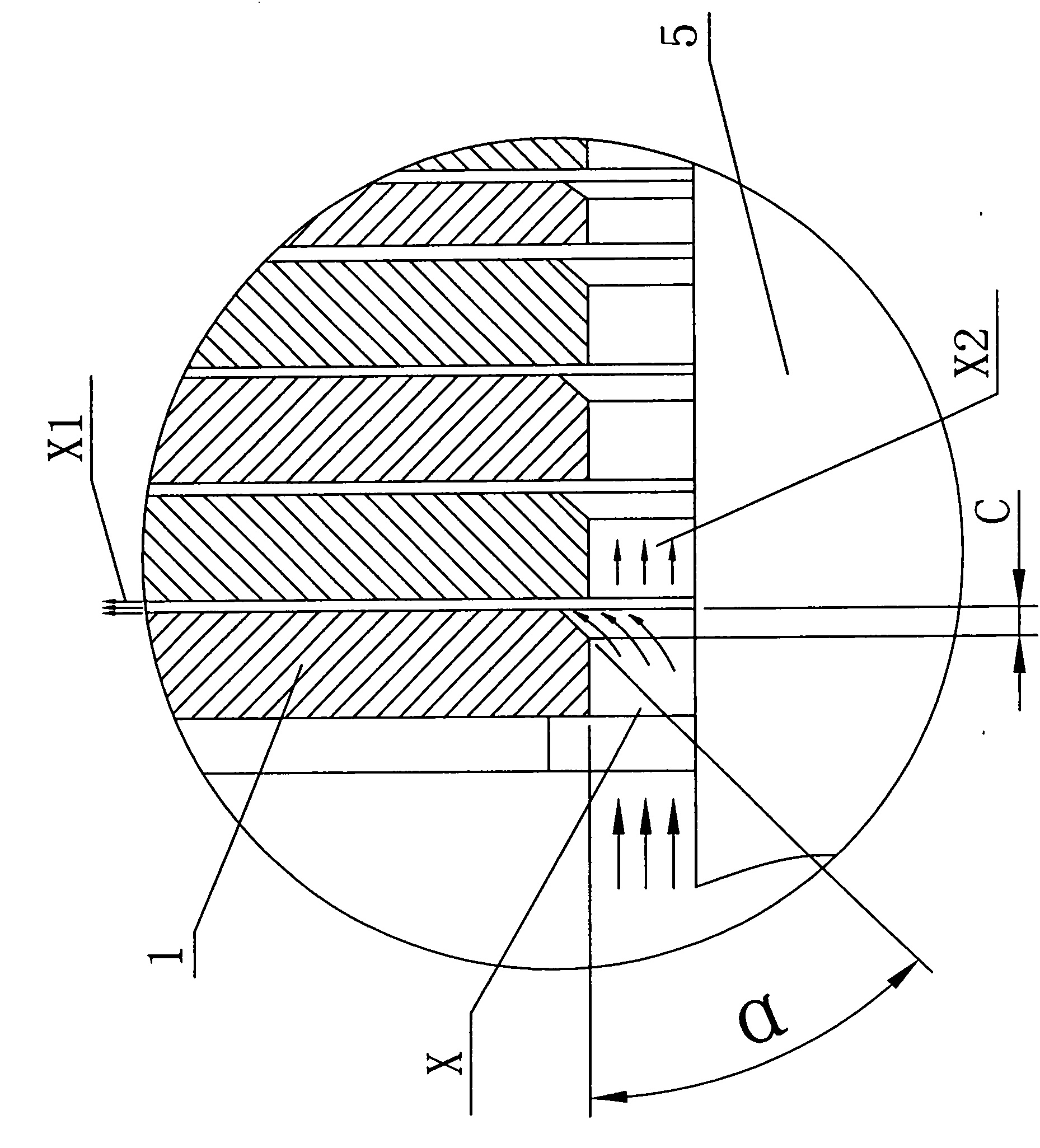

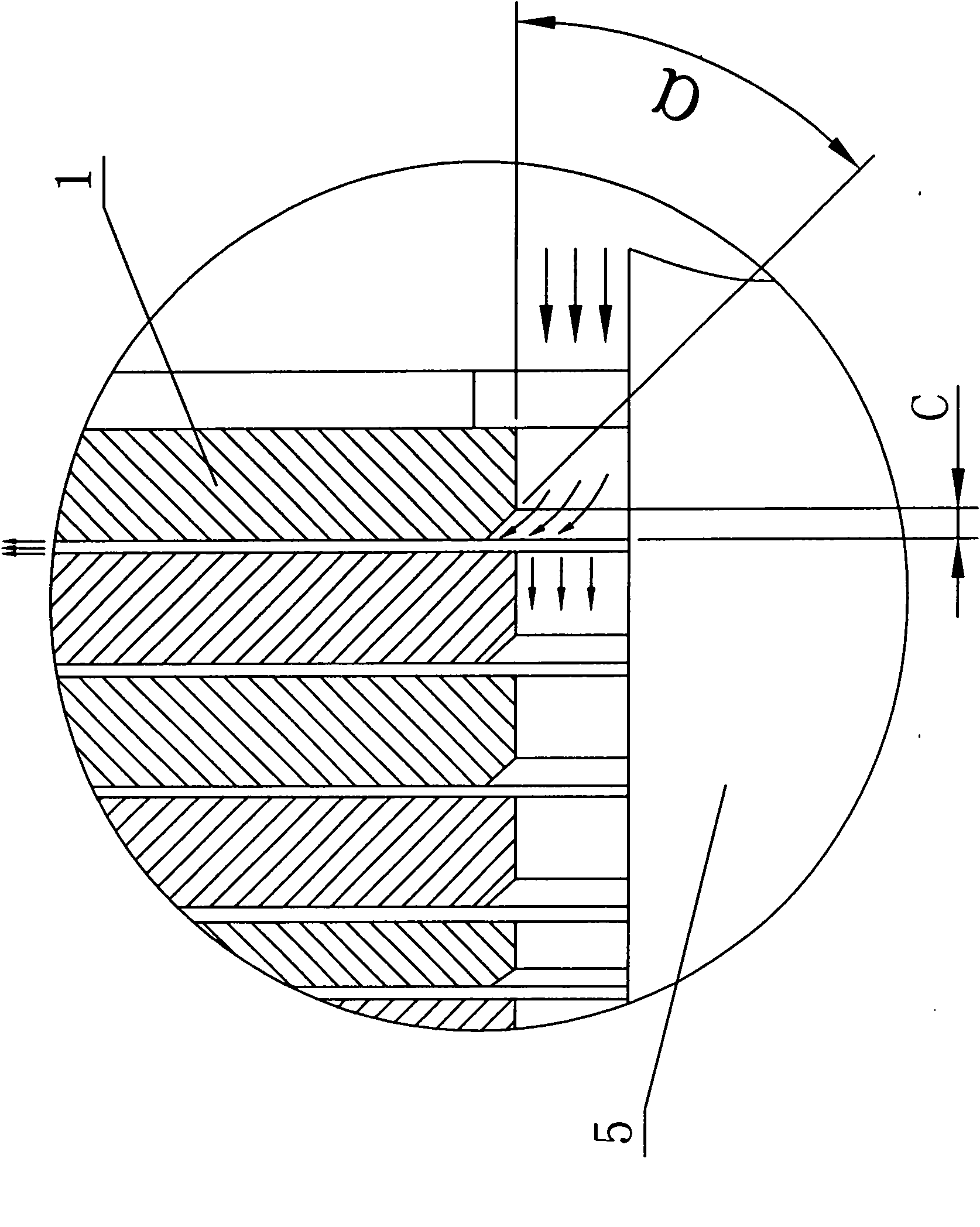

[0008] Specific implementation mode one: as Figure 1~5 , Figure 6a~6c As shown, a large-scale air-cooled turbogenerator stator that can improve the ventilation and cooling effect described in this embodiment includes two pressure plates 3, at least two positioning ribs 2 and a plurality of iron core segments 1, and each iron core segment 1 The outline shape is circular, a plurality of iron core segments 1 are coaxially arranged to form a stator main body and the stator main body is placed between two pressure plates 3, and the at least two positioning ribs 2 are evenly distributed in the axial direction on the On the outer surface of the stator main body, the at least two positioning ribs 2 form an air gap 4 between every two adjacent iron core segments 1, the air gap 4 is a radial ventilation groove and the radial ventilation groove The width W of the at least two positioning ribs 2 is 6 mm to 8 mm, and one end of the at least two positioning ribs 2 is fixedly connected to...

specific Embodiment approach 2

[0009] Specific implementation mode two: as figure 1 As shown, the iron core segments 1 located at both ends of the stator main body in this embodiment refer to ten to fifteen iron core segments 1 located at both ends of the stator main body, that is, from the outermost ends of the two ends of the stator main body to the The above-mentioned chamfers are all formed on the ten to fifteen iron core segments 1 of the inner number. The core sections of the 200MW air-cooled turbogenerator are not equally spaced in the axial direction, and the thickness of the iron core section from the end is relatively thick, so the electromagnetic loss generated by each iron core section at the end is larger than that of the middle section. When the width of the ventilation ditch is constant, The ability of the fluid in the ventilation ditch to take away the heat of the heating element is certain, causing the iron core temperature of the end section to be higher than that of the middle section. R...

specific Embodiment approach 3

[0010] Embodiment 3: The chamfer α in this embodiment is 65°. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com