System and method suitable for low-pressure steam-water separation

A steam-water separation, low-pressure technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high separator resistance, limited separation efficiency, and high steam parameters, achieve high removal efficiency, and improve vapor-liquid The effect of improving separation efficiency and flow uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

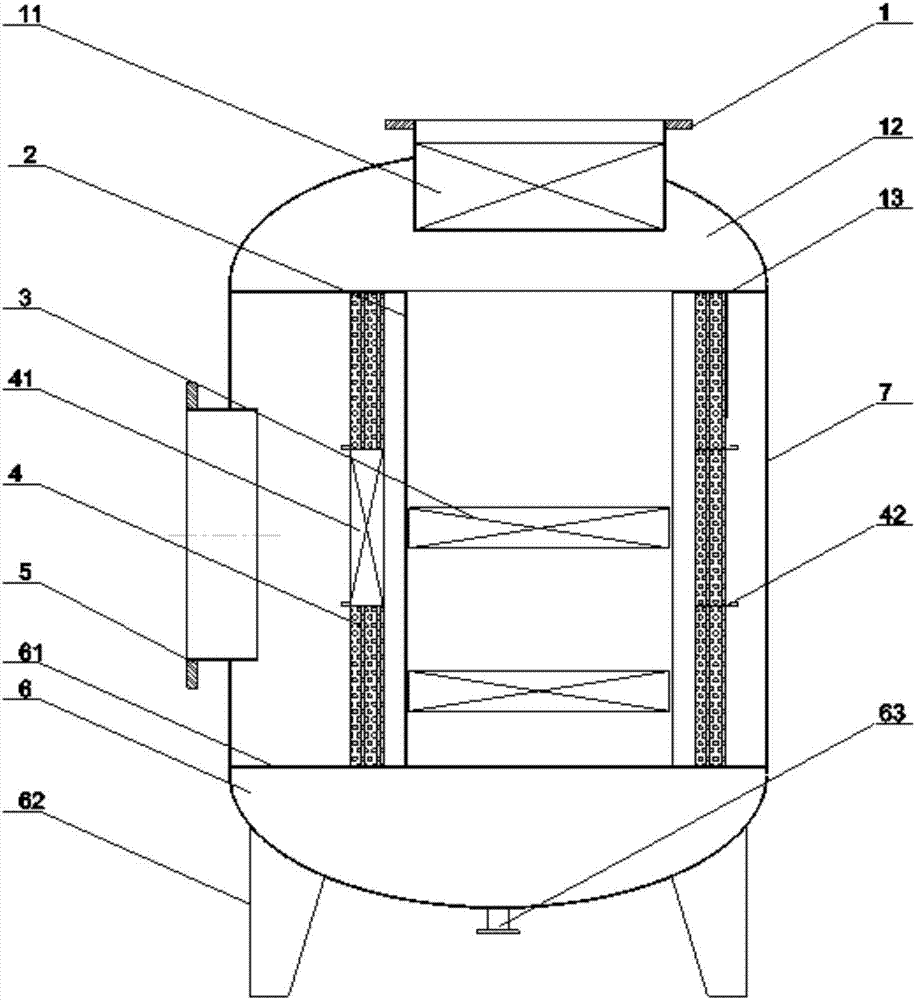

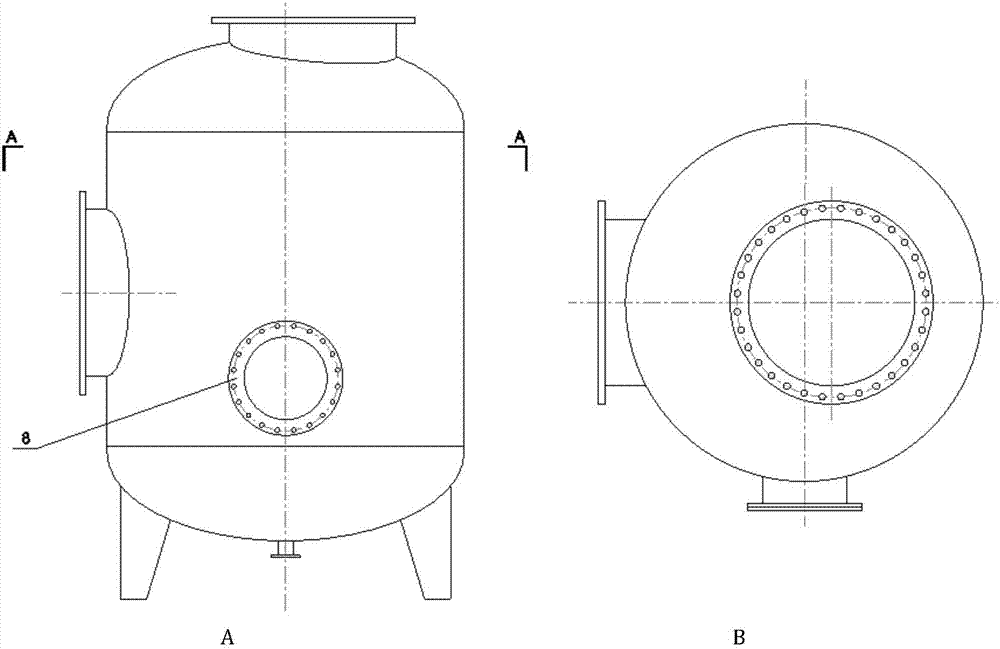

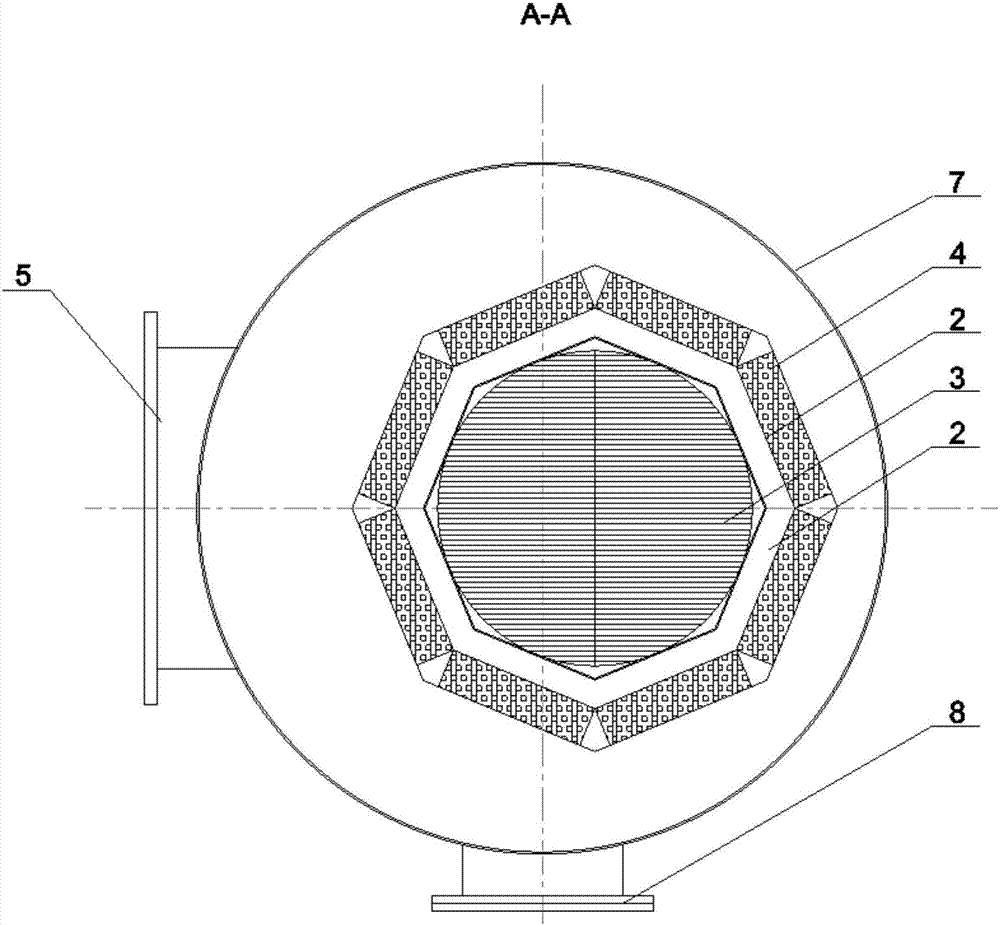

[0043] Such as figure 1 As shown, this embodiment includes: steam inlet 1, inlet steam distribution device 11, buffer steam chamber 12, steam chamber partition 13, flow uniform distribution cylinder 2, baffle separator 3, wire mesh separation system 4 , Reserved separation area 41, independent hydrophobic device 42, steam outlet 5, hydrophobic chamber 6, hydrophobic chamber partition 61, hydrophobic chamber base 62, hydrophobic outlet 63, vapor-liquid separator housing 7, manhole door 8.

[0044] The specific working process of this device is as follows:

[0045] The steam fluid with a certain humidity enters the steam-water separation device through the steam inlet 1 at a relatively high flow rate, and then enters the inlet steam flow uniform distribution device 11 for preliminary flow equalization, and enters the buffer steam chamber 12 after passing through the outlet of the flow equalization device 11, and after preliminary buffer Afterwards, the outlet of the buffer stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com